- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Keyou

-

Application:

-

Wood carving and trimming

-

Packing:

-

1ps/ Plastic Box

-

Controlling Mode:

-

CNC Tooling System

-

Product name:

-

1/2'' and 1/4''sharp mouth carving bits

-

Keywords:

-

sharp mouth carving bits

-

Machine Type:

-

ANCA

-

Shank Diameter:

-

1/2'' and 1/4''

-

Use:

-

CNC Woodworking

Quick Details

-

Material:

-

Carbide

-

Coating:

-

AlTiN

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

Keyou

-

Application:

-

Wood carving and trimming

-

Packing:

-

1ps/ Plastic Box

-

Controlling Mode:

-

CNC Tooling System

-

Product name:

-

1/2'' and 1/4''sharp mouth carving bits

-

Keywords:

-

sharp mouth carving bits

-

Machine Type:

-

ANCA

-

Shank Diameter:

-

1/2'' and 1/4''

-

Use:

-

CNC Woodworking

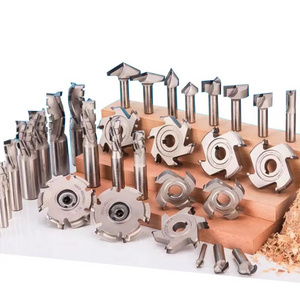

Products Description

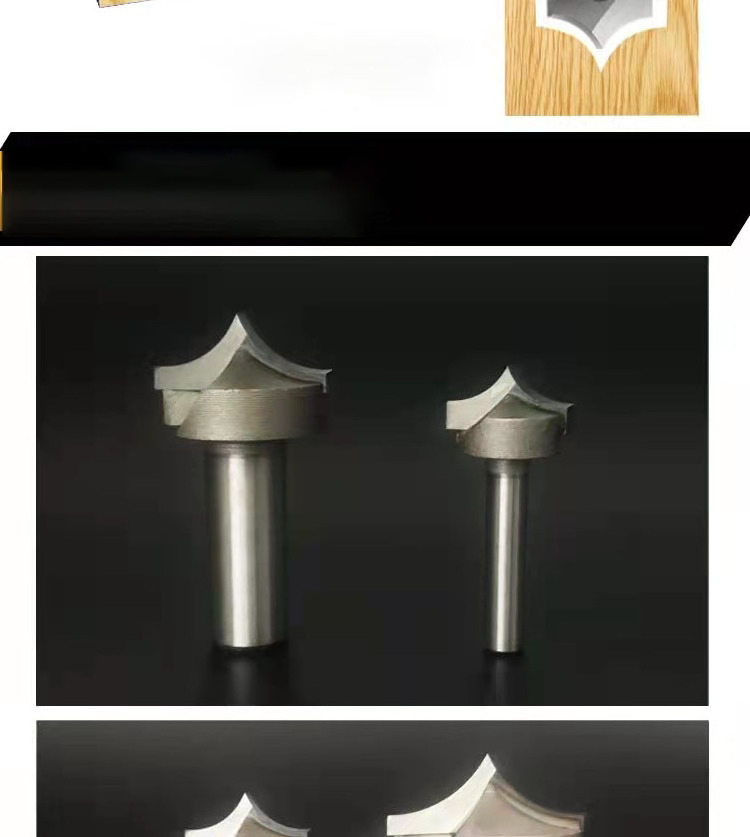

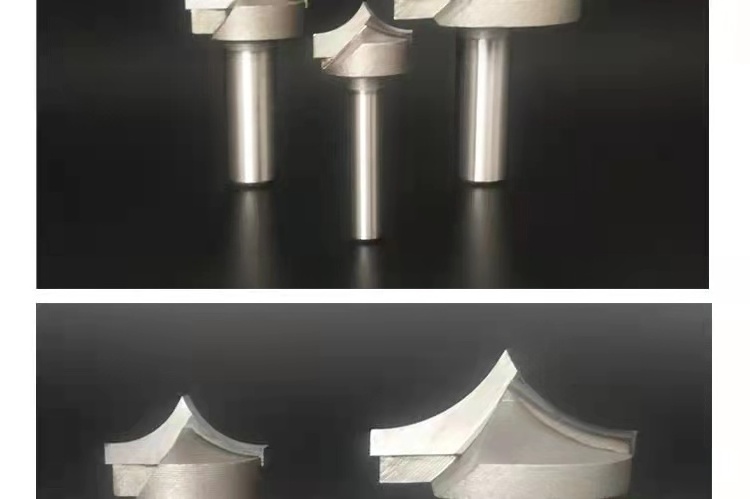

<h2>woodworking sharp mouth carving bits 1/2 and 1/4 shank solid carbide end mills router bits<h2>

Engraving machine for 1 / 2 handle

Trimming machine for 1 / 4 handle

This product is a high-grade tungsten steel alloy cutter head

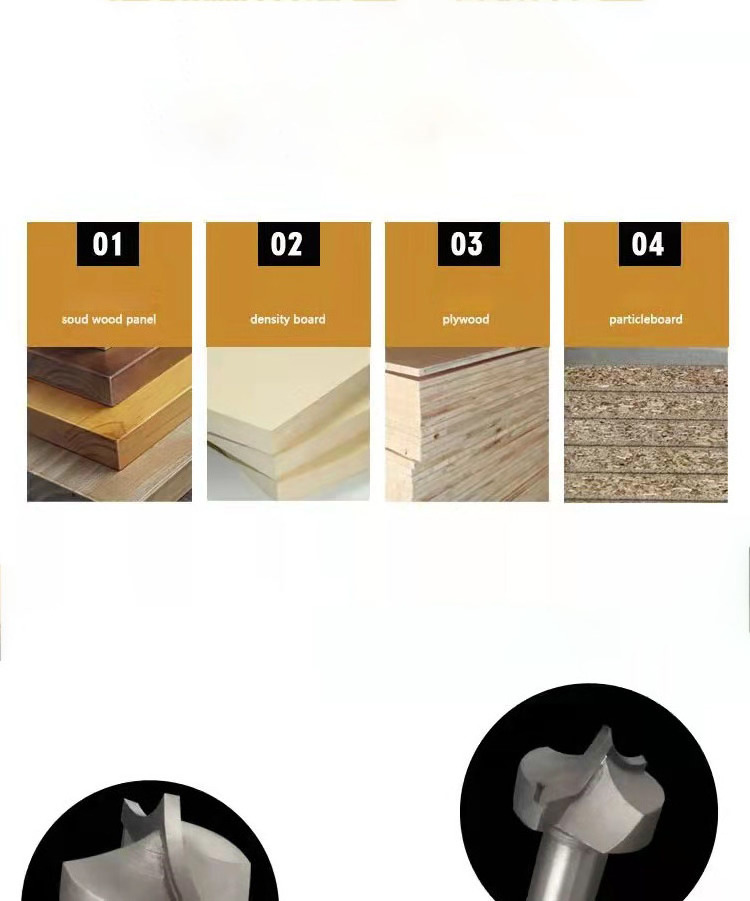

It is suitable for density board, wood board and hardwood

Characteristic:

1. shank: 1/4 and 1/2 inch

2. Industrial Quality

3. C3 carbide

4. Solid Hardened carbon steel body

5. Anti-Kickback Design

6. Build-up Resistant Teflon Coating

7. Lifetime Warranty

8. Satisfaction Guaranteed.

1. shank: 1/4 and 1/2 inch

2. Industrial Quality

3. C3 carbide

4. Solid Hardened carbon steel body

5. Anti-Kickback Design

6. Build-up Resistant Teflon Coating

7. Lifetime Warranty

8. Satisfaction Guaranteed.

PRODUCT SPECIFICATIONS

|

Type NO

|

Size

|

Type NO

|

Size

|

|

1

|

1/4''*1/2

|

9

|

1/2*7/8

|

|

2

|

1/4''*3/4

|

10

|

1/2*1

|

|

3

|

1/4*7/8

|

11

|

1/2*1-1/8

|

|

4

|

1/4*1

|

12

|

1/2*1-3/8

|

|

5

|

1/2*3/8

|

13

|

1/4*3/8

|

|

6

|

1/2*1/2

|

14

|

1/2*5/8

|

|

7

|

1/4*5/8

|

15

|

1/2*1-5/8

|

|

8

|

1/2*3/4

|

16

|

1/2*2

|

DIRECTIONS FOR USE

DIRECTIONS FOR USE

1. In order to prevent the tools from twisting due to excessive pressure, all tools are designed to rotate clockwise.

2. When all tools are finished, they pass the balance test to ensure that there is no doubt of diameter jump, so as to guarantee again. The tool does not swing and jump during use, please pay attention to choose suitable mechanical equipment and excellent jacket.

3. The jacket must choose the appropriate size. If it is found that the jacket is not round enough or worn, it will cause the jacket If the tool cannot be clamped normally and correctly, please replace the intact jacket with standard specifications immediately to avoid the tool being in Under high-speed rotation, the handle vibrates, and then a dangerous situation of flying off or twisting occurs.

4. The installation of the tool shank shall be in accordance with EU regulations. For example, the clamping depth of the 12. 7mm shank diameter must reach 24mm, In order to maintain the pressure bearing range of the handle.

5. Setting of rotating speed: cutting tools with larger outer diameter should be set according to the following tachometer, and push slowly to maintain a uniform speed Propulsion speed, do not stop the propulsion action during cutting.

6. When the tool is blunt, please replace it with a new one and do not continue to use it to avoid tool breakage and work injury. Outside.

7. When using a tool, please select a tool with a blade length greater than the workpiece, for example, to mill a groove with a depth of 12.7mm, Please select tools with a cutting edge length of 25.4mm and avoid tools with a cutting edge length equal to or lower than 12.7mm.

8. When operating and processing, please wear safety glasses and push the handle safely. It is also required when using desktop machinery and equipment.

|

suggested Router Speeds

|

|

|

|

Bit Diameter

|

Maximum Router Speeds

|

|

|

1''

|

24000RPM

|

|

|

1-1/4'' -2''

|

18000RPM

|

|

|

2-1/4'' -2-1/2''

|

16000RPM

|

|

|

3'' -3-1/2''

|

12000RPM

|

|

Hot Searches