- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Banarta

-

Model Number:

-

XPS

-

Type:

-

XPS Foam Board

-

Product name:

-

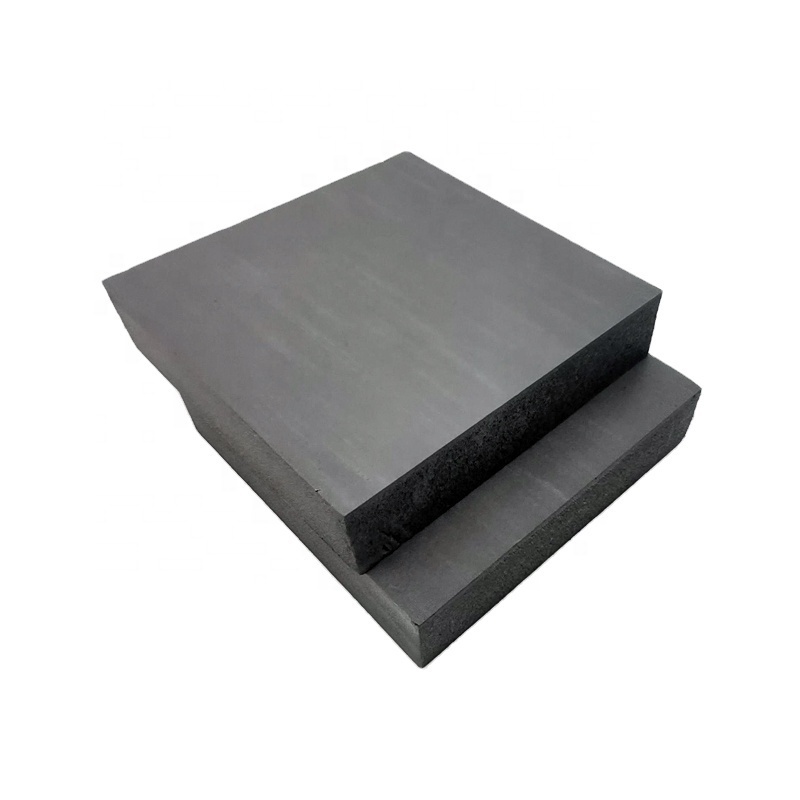

Graphite XPS foam board

-

Color:

-

Black

-

Length:

-

1200mm/1250mm/2400mm

-

Width:

-

600mm

-

Thickness:

-

6-120mm

-

Compress Strength:

-

150~1000Kpa

-

Flame Retardant:

-

B1 B2

-

Thermal Conductive:

-

0.028W/m.k

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training, Onsite Inspection, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Banarta

-

Model Number:

-

XPS

-

Type:

-

XPS Foam Board

-

Product name:

-

Graphite XPS foam board

-

Color:

-

Black

-

Length:

-

1200mm/1250mm/2400mm

-

Width:

-

600mm

-

Thickness:

-

6-120mm

-

Compress Strength:

-

150~1000Kpa

-

Flame Retardant:

-

B1 B2

-

Thermal Conductive:

-

0.028W/m.k

Products Description

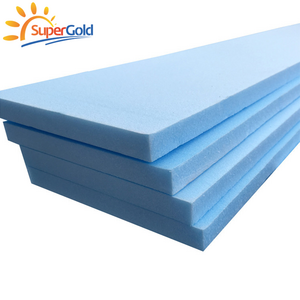

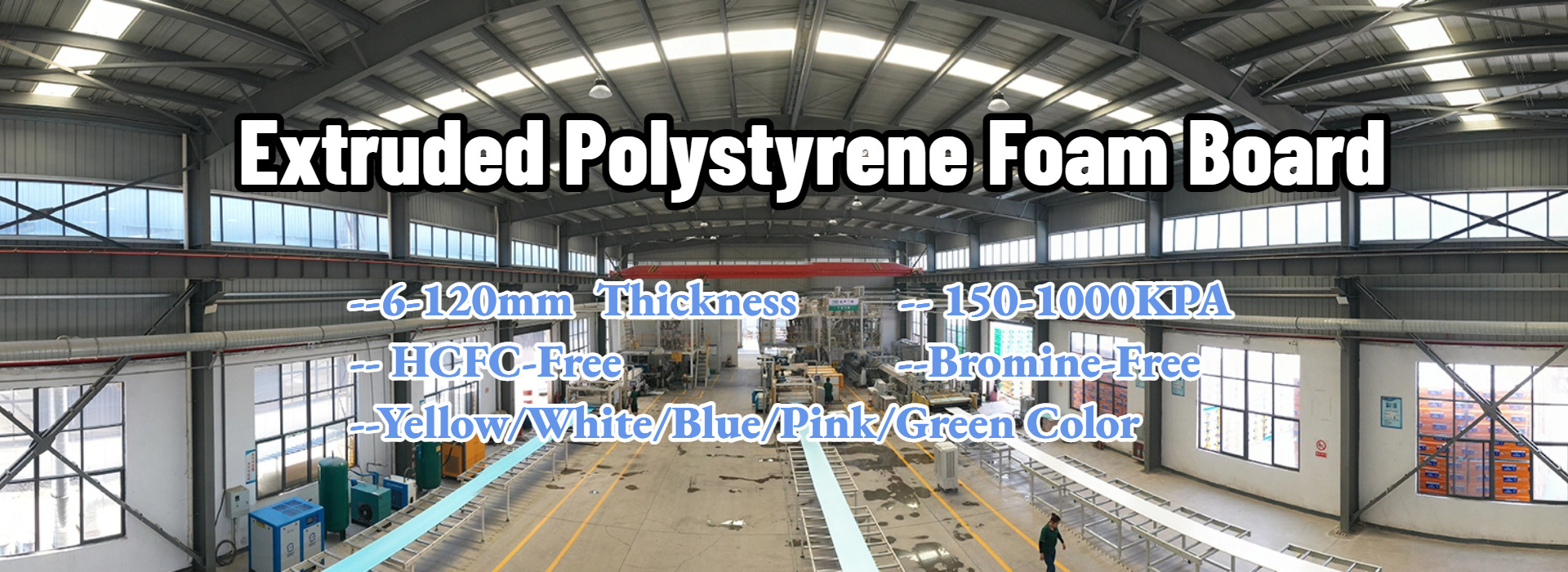

Extruded Polystyrene Foam Board

XPS foam board is a rigid thermoplastic material manufactured from polystyrene(GPPS).

Its cell is closed,continuous and alveolate, every cell wall is interlinked and consistent.

The special structure makes the products have very good heat resistance, high humidity resistance, low water absorption,good sound insulation, high compressive strength, creep resistance and good dimensional stability.

The property of XPS foam board is stabe and light-weight, easy to transport and cut.

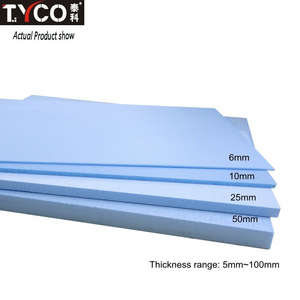

Product Paramenters

|

Features

|

Specifications

|

|

Length

|

1200mm /2400mm /3000mm

|

|

Witdth

|

600mm/1200mm

|

|

Thickness

|

6mm-120mm

|

|

Compressive Strength

|

150-1000KPa

|

|

Dimensional stability70℃±2℃,48h

|

1-2%

|

|

Color

|

Black

|

|

Water absorption

|

≤1.5%

|

|

Water vapour permeability

|

≤3.0% (ng/m.s.pa )

|

|

Thermal conductivity

|

≤0.026W/M.K

|

|

Surface

|

Skin/ Without skin / Slotting / Roughening

|

|

Fire Rating

|

B1 (Oxygen Index ≥27)B2 (Oxygen Index ≥24 ) B3 (Non-Fireproof)

|

|

Working Temperature

|

-30℃-80℃

|

Typical Application

Building Insulation

XPS is considered a good insulator. It has excellent thermal insulation. Its closed-cell structure minimizes heat loss, providing high levels of insulation performance.

It helps maintain constant temperatures, improves energy efficiency, and reduces heating and cooling costs. It is widely used in various of building insulation such as roof,wall and floor etc....

Cold Storage Insualtion

With its good and stable thermal conductive,low water absorption and high compressive strength,

XPS gets very great advantages in cold storage insulation as below:

--Extremely durable.

--Capable of bearing heavy loads.

--Highly resistant to moisture.

--Guaranteed to have low, stable and predictable thermal conductivity.

--Able to withstand the stresses of temperature changes and freeze/thaw cycles.

Refrigerated truck

Comparing to traditional materials, XPS has its advangtages in Refrigerated truck application :

--Stable performance and anti-aging:

--Resistance to compression:

--Water resistance

--Lightweight

--Resistance to deformation

--Recyclable no pollution.

--Easy to cut shapes

Roadbed Construction

Many studies shows, because XPS foam board have the engineering properties such as durability, high compressive strength, excellent thermal efficiency, etc, it make XPS sheets very suitable for roadbed construction, especially in areas with extreme climate conditions,to reduce the frosting effect of the road, extend the life of the road and protect it.

It has been considered as the most suitable, convenient and economical solution for structural integrity. It is widely used in the roadbeds construction of airport , highways, high-speed rails etc...

Greenhouse Hydroponic culture

The xps foam board for hydroponics have a bulk density to allow for optimum thermal insulation. They have a standard dimensional size but are highly customizable by the manufacturers and suppliers to suit the buyer's needs. xps foam board for hydroponics don't absorb moisture so that they are mildew and mold resistant.

This method is the most common for large commercial aquaponics growing leafy green crops such as lettuce, kale, chard, mustard, collards, basil, mint and most herbs.

Details Images

Roughening + Slotting Surface

XPS Foam Board with roughening & slotting surface is suitable for the application of sandwich panel

Roughening Surface

XPS Foam Board with Roughening surface could get better thickness tolerance up to ±0.5mm

Skin Surface

The original surface of XPS Foam Board is skin surface. Skin surface could provide better water absorption.

Packages&Loading

Normal Package & Loading of XPS Foam Board

Our normal package of XPS foam board is by polybag. We can also provide customized package for clients, such as carton package if you need.

Normally, 1X40HQ can load about 66-68 CBM of XPS Foam Board. 1X20GP can load about 25CBM.

Hot Searches