- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

22KW

-

Weight:

-

1700

-

Dimension(L*W*H):

-

3700x765 x850

-

Model:

-

LWS350

-

Separation mode:

-

Settlement type

-

Operation mode:

-

Continuous type

-

Installation mode:

-

horizontal

-

Material:

-

SUS304

-

Temperature range:

-

-80-120℃

-

After Warranty Service:

-

Online support

-

Diameter(mm):

-

350

-

Drum Work Speed(r/min):

-

4200

-

Material Handling Capacity(m³/h):

-

4

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New Product 2022

-

Brand Name:

-

HX Centrifuge

-

Voltage:

-

220V/380V

-

Power:

-

22KW

-

Weight:

-

1700

-

Dimension(L*W*H):

-

3700x765 x850

-

Model:

-

LWS350

-

Separation mode:

-

Settlement type

-

Operation mode:

-

Continuous type

-

Installation mode:

-

horizontal

-

Material:

-

SUS304

-

Temperature range:

-

-80-120℃

-

After Warranty Service:

-

Online support

-

Diameter(mm):

-

350

-

Drum Work Speed(r/min):

-

4200

-

Material Handling Capacity(m³/h):

-

4

Products Description

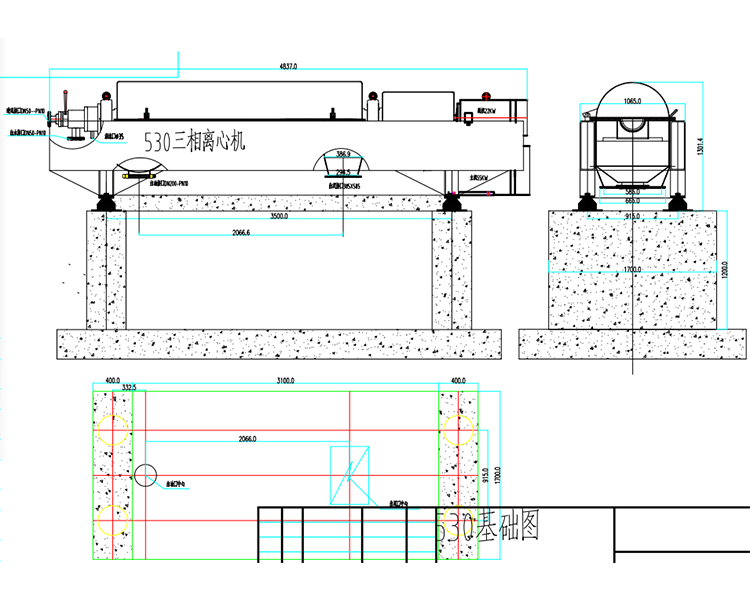

LWS Series Horizontal Spiral Discharing Sedimentation Centrifuge

Solid-Liquid Separation System

LWS350 three-phase horizontal screw centrifugal dehydrator is a high-speed, stable and efficient automatic control equipment, which is mainly used for solid-liquid oil clarification and separation in food waste treatment, petrochemical and other industries. All parts and components in contact with materials are made of high-grade stainless steel materials, which effectively reduces the corrosion of the separated materials and the surfaces of the parts in contact. The separated materials enter the drum of the centrifuge. Under the strong centrifugal force field, the materials are accelerated by the accelerating cone and then enter the material separation zone between the screw pusher and the straight section drum. The solid materials with large specific gravity move along the direction of the drum wall, accumulate in the sediment zone of the drum wall, and are transported out of the centrifuge by the screw pusher. The liquid phase materials with small specific gravity are pushed on the surface of the sedimentation tank by the heavy phase materials, and move toward the light phase outlet under the axial force of the cone section drum. The separated light phase material is thrown out by the centrifugal force of the drum itself, and flows out of the centrifuge after free convergence.

Extraction Cycle

|

1.Start Machine

|

The main engine starts and accelerates automatically. When the predetermined index is reached and the drum speed reaches the feeding speed, the feeding valve opens.

|

|

2

.Feedstock

|

The suspension waiting to be separated enters the silo of the screw pusher from the feeding pipe, and enters the drum through the outlet of the silo after initial acceleration.

|

|

3.Solid-Liquid Separation

|

The suspension passes the outlet of the compart ment and into the revolving drum. In response to the centrifugal force,the suspension in the drum is quickly divided into two phases:the heavier solid phase deposits to the inner wall of the drum and

driven by the differential gear which results in the nonsynch ronous movement between the spiral feeder and the drum. |

|

4.Solid

|

The solid phase is transferred into the small end for further dehydration and is finally discharged through waste exit.

|

|

5.Liquid

|

The separated liquid is discharged through the big end or driven out by the centripetal pump.

|

Product Paramenters

|

Model

|

LWS350

|

|

Basket Dia

|

350mm

|

|

Drum length

|

1400mm

|

|

Length to Diameter Ratio

|

4

|

|

Drum speed

|

4200rpm

|

|

Differential RPM

|

0-30 rpm

|

|

Differential adjustment accuracy

|

0.1 to 0.5 rpm

|

|

Material Handling Capacity(m³/h)

|

1-4

|

|

Separating Factor Max

|

3454

|

|

Water Content

|

≤80%

|

|

Feed Solids

|

1-10%

|

|

Solids Recovery Rate

|

98%

|

|

Noise

|

≤70dB(A)

|

|

Overall Dimensions

|

3700x765 x850mm

|

|

Machine Weight

|

2050 Kg

|

|

Maximum Service Weight

|

500Kg

|

|

Motor Model

|

YD160-4/2

|

|

Motor Power

|

22KW

|

Details Images

Related Products

About Us

Certifications

Packaging&Shipping

Our Service

Pre-service

--24 Hours online service for your consult.

--Help choose right model,and a series of service,person,advise.

Middle service

--Give you best offer

--Provide discount for many sets order

--Do customer's request:

--Choose payment term you convienent.

--Promptly production and delivery,inform you in time.

--Can provide invoice value as you like to decrease your tax.

After sale service

--1 year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Free change for some parts

--Remote control technical consult

--Free installation DVD

--Maintenance plan

Hot Searches