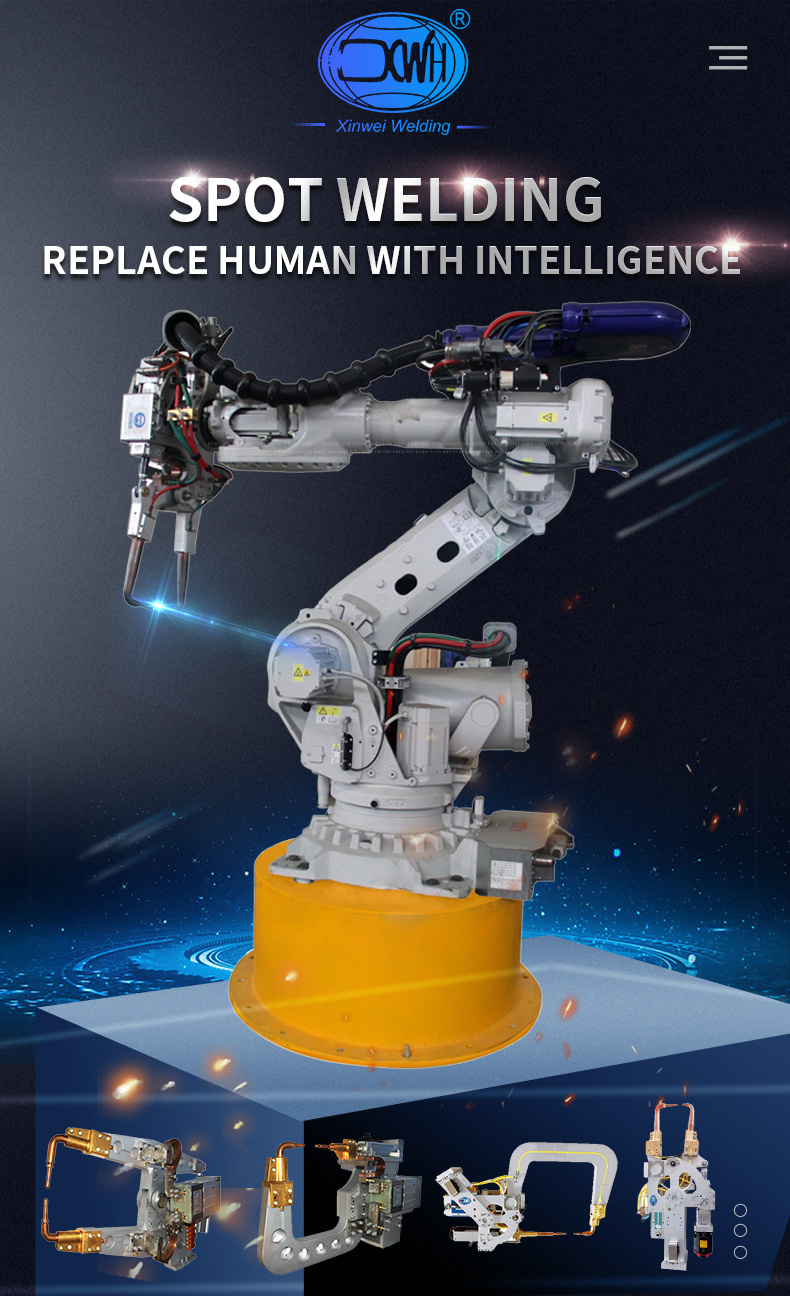

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

800

-

Voltage:

-

220V/380V

-

Rated Capacity:

-

40-200KVA

-

Rated Duty Cycle:

-

50%

-

Dimensions:

-

170cm*90cm*200cm

-

Usage:

-

Welding sheet metal

-

Product Name:

-

Projection Weld

-

Machine type:

-

Resiatance Welding Machine

-

Application:

-

Sheet Metal Welding

-

Function:

-

Galvanized Sheet Welding Machine

-

Keyword:

-

Multi Spot Welding Machine

-

Welding material:

-

Stainless Steel Carbon Steel Metal

-

MOQ:

-

1 Set

-

After Warranty Service:

-

Video technical support, Online support and Spare parts

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training

-

Certification:

-

ISO,CE

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

XinWeiHan

-

Weight (KG):

-

800

-

Voltage:

-

220V/380V

-

Rated Capacity:

-

40-200KVA

-

Rated Duty Cycle:

-

50%

-

Dimensions:

-

170cm*90cm*200cm

-

Usage:

-

Welding sheet metal

-

Product Name:

-

Projection Weld

-

Machine type:

-

Resiatance Welding Machine

-

Application:

-

Sheet Metal Welding

-

Function:

-

Galvanized Sheet Welding Machine

-

Keyword:

-

Multi Spot Welding Machine

-

Welding material:

-

Stainless Steel Carbon Steel Metal

-

MOQ:

-

1 Set

-

After Warranty Service:

-

Video technical support, Online support and Spare parts

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training

-

Certification:

-

ISO,CE

ChengDu Xinweihan is one of the leading welding equipment manufacturer in china,

Specialized in manufacturing and provide customers with a complete set of welding solutions.

A R&D team of more than 20 engineers., and a 20000 sq.m manufacturer, which guarantees that we can offer customers the most professional welding advice and after-sales service.

And we have our own overseas technical service teams in many countries in Southeast Asia and South America to provide customers with on-site installation and maintenance services.

(Please contact us to ask if there is a technical team in your country)

Product Description

The metal leaf projection welding machine is composed of components such as a frame, conductive sheet, welding head moving mechanism, electrode components, welding transformer (power frequency), welding machine controller, air circuit system, cooling water system, etc.

Welding action principle: Press the start button, the welding cylinder will be welded from left to right in sequence, and the equipment action will be completed by the welding controller without manual intervention until all welding points are completed. Each welding head completes projection welding of 4 welding points, with a total of 8 protrusions welded in one clamping process, which easily ensures the welding quality of each welding point. The welding pressure and welding current of each welding head are independently adjustable. The movement direction of each welding head is horizontal, and transverse welding points can be welded. Especially suitable for large workpieces, achieving efficient welding when installation is inconvenient.

Technical Parameters

|

Item/Model

|

DN-40

|

DN-63

|

D(T)N-80

|

D(T)N-100

|

D(T)N-125

|

D(T)N-160

|

D(T)N-200

|

|

Rated power At 50%(KVA)

|

40

|

63

|

80

|

100

|

125

|

160

|

200

|

|

Rated primary power(V)

|

380

|

380

|

380

|

380

|

380

|

380

|

380

|

|

Secondary Voltage(V)

|

5.2

|

6.7

|

7.9

|

8.3

|

8.6

|

9.1

|

10.6

|

|

Rated frequency(HZ)

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

|

Max.Short Circuit Current(KA)

|

14

|

15

|

16

|

18

|

20

|

28

|

34

|

|

Max. weld power(KVA)

|

62

|

86

|

170

|

280

|

300

|

330

|

410

|

|

Throat(MM)

|

400

|

400

|

400

|

450

|

450

|

450

|

450

|

|

Max.Froce at electrodes(N)

|

6000

|

6000

|

10000

|

10000

|

10000

|

12000

|

12000

|

|

Working stroke(MM)

|

20

|

20

|

30

|

40

|

40

|

50

|

50

|

|

Cooling Water Consumpion 2.5bar(L/min)

|

6

|

6

|

8

|

8

|

8

|

10

|

10

|

|

Electrodes tip(MM

)

|

Φ13*45

|

Φ13*45

|

Φ16*45

|

Φ16*45

|

Φ16*45

|

Φ20*45

|

Φ20*45

|

|

Arms(MM)

|

Φ50*150

|

Φ50*150

|

Φ80*220

|

Φ80*220

|

Φ80*220

|

Φ80*220

|

Φ80*220

|

|

Projection Clamping Plate(MM)

|

125*125

|

125*125

|

200*200

|

200*200

|

200*200

|

200*200

|

200*200

|

|

Max.Welding

Capaciry A3 steel(MM) |

2.5+2.5

|

3+3

|

4+4

|

4.5+4.5

|

5+5

|

5+5

|

6+6

|

Main Features

1. The body is designed for shock resistance, seismic resistance, and high rigidity, and is finely machined to meet the installation and load strength of each component. Multiple reinforcing ribs have been welded inside the frame to ensure the rigidity of the equipment and minimal deformation during the welding process, ensuring the stability of welding and the safety of manual use.

2. The upper electrode is pressurized by a gas-liquid pressure cylinder, making pressure adjustment convenient and accurate.

3. The backup dedicated air storage tank for welding machines is beneficial for reducing the fluctuation of welding pressure and ensuring the stability of welding force;

4. The upper electrode moves horizontally forward and backward, and the welding stroke and workpiece operation stroke are independent, while the lower electrode is fixed; Easy to operate.

5. The descent and ascent speed of the pressure head can be adjusted arbitrarily, easing the pressure impact on the workpiece and reducing noise;

6. The combination cylinder of aluminum alloy cylinder barrel, low damping sealing ring, and light friction ring, equipped with a pilot large flow electromagnetic directional valve, has faster response speed and extremely sensitive follow-up performance, achieving extremely high tapping speed.

Detail Images

Different Angles of Product

More details,

please contact!

Hot Searches