- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KECHUANG

-

Voltage:

-

According to customer needs

-

Dimension(L*W*H):

-

1800*1100*1400MM

-

Weight:

-

1500KG-3000KG

-

PLASTIC EXTRUDER:

-

PLASTIC SINGLE SCREW EXTRUDER

-

TWIN SCREW EXTRUDER:

-

PVC EXTRUDER

-

WPC EXTRUDER:

-

PVC PROFILE EXTRUDER

-

SCREW & BARREL MATERIAL:

-

38CrMnALA

-

MOTOR:

-

SIMENS

-

CONTACTOR:

-

SIMENS

-

PLC CONTROL SYSTEM:

-

SIMENS

-

INVERTER:

-

ABB

-

TEMPERATURE METER:

-

RKC

-

ELECTRIC BUTTONS:

-

SCHENEILDER

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Viet Nam, Philippines, Brazil, Peru, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Kazakhstan, Ukraine, Uzbekistan

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

ISO9001:2000; CE; BV

Quick Details

-

Screw Design:

-

Double-screw

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

40 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KECHUANG

-

Voltage:

-

According to customer needs

-

Dimension(L*W*H):

-

1800*1100*1400MM

-

Weight:

-

1500KG-3000KG

-

PLASTIC EXTRUDER:

-

PLASTIC SINGLE SCREW EXTRUDER

-

TWIN SCREW EXTRUDER:

-

PVC EXTRUDER

-

WPC EXTRUDER:

-

PVC PROFILE EXTRUDER

-

SCREW & BARREL MATERIAL:

-

38CrMnALA

-

MOTOR:

-

SIMENS

-

CONTACTOR:

-

SIMENS

-

PLC CONTROL SYSTEM:

-

SIMENS

-

INVERTER:

-

ABB

-

TEMPERATURE METER:

-

RKC

-

ELECTRIC BUTTONS:

-

SCHENEILDER

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Viet Nam, Philippines, Brazil, Peru, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Kazakhstan, Ukraine, Uzbekistan

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

ISO9001:2000; CE; BV

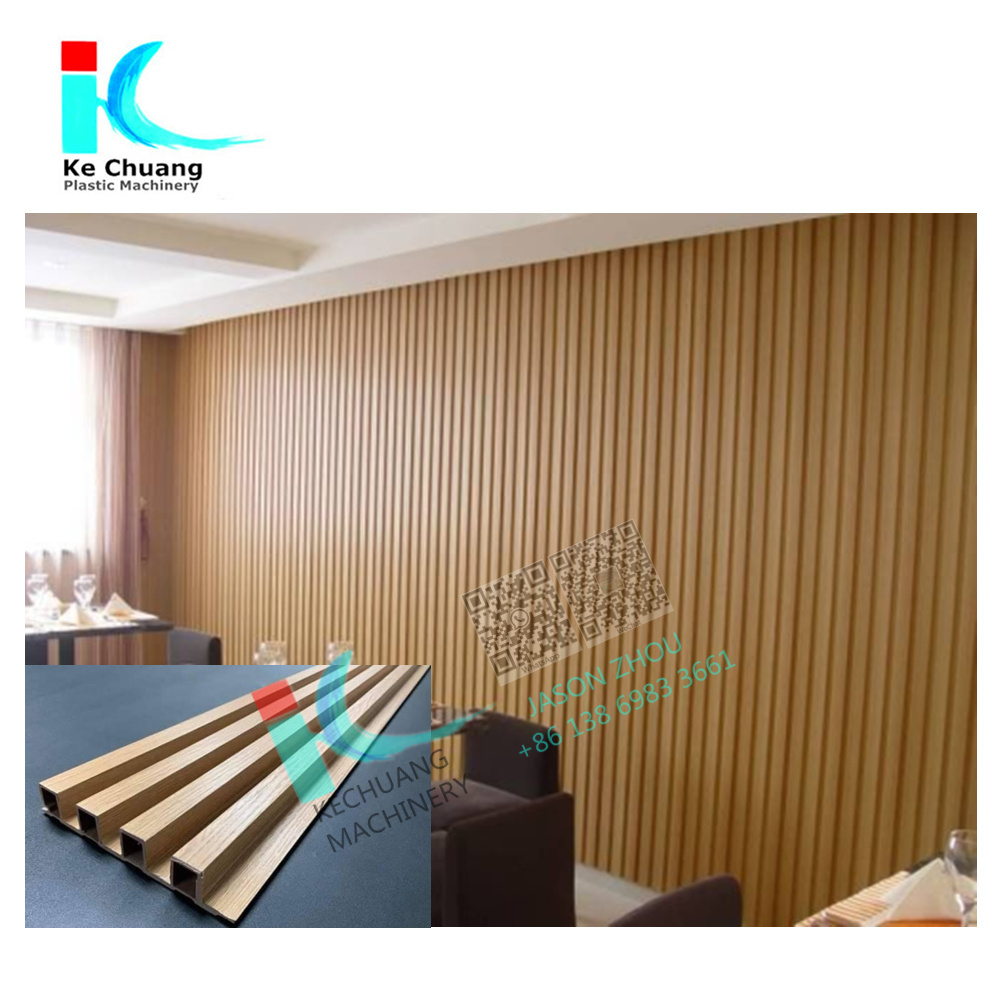

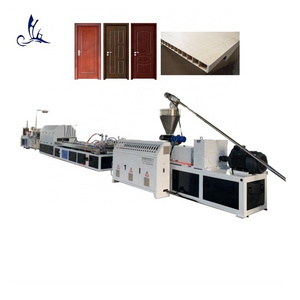

WPC WALL PANEL MAKING MACHINE

PLASTIC WOOD PROFILE EXTRUDER

WPC PROFILE EXTRUDOR MACHIENRY

PVC/PP/PE WOOD PROFILE EXTRUDER

PVC/PP/PE WOOD PROFILE MAKING MACHINE

I. Main description:

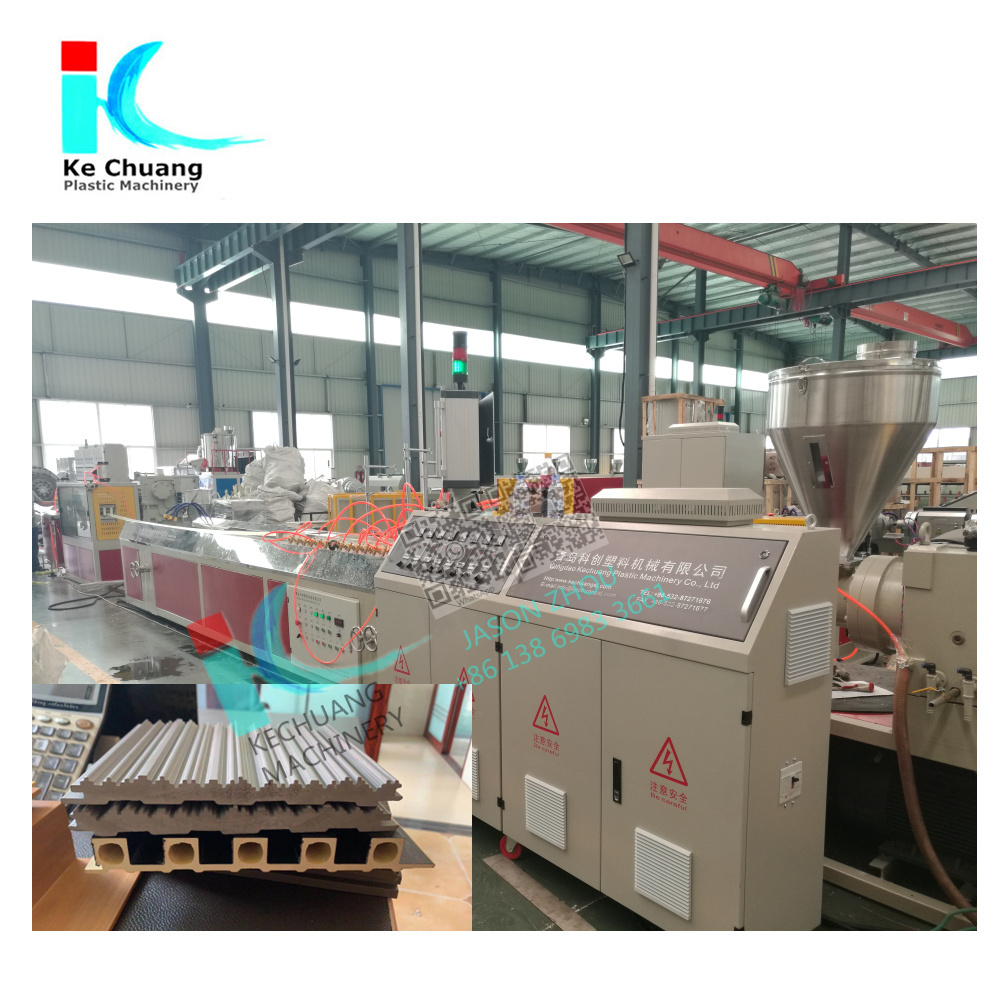

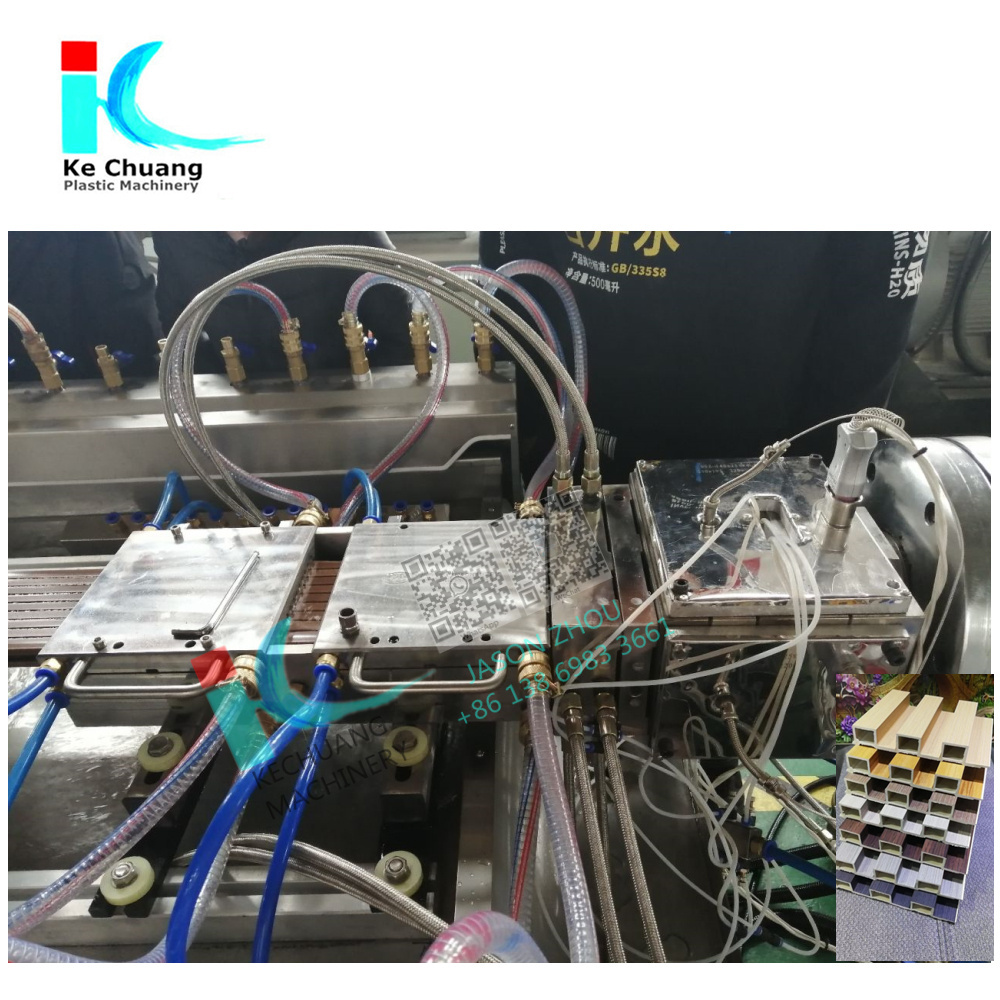

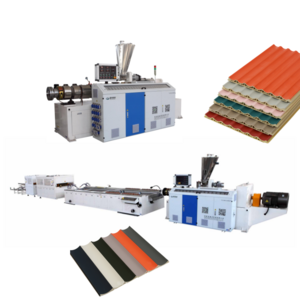

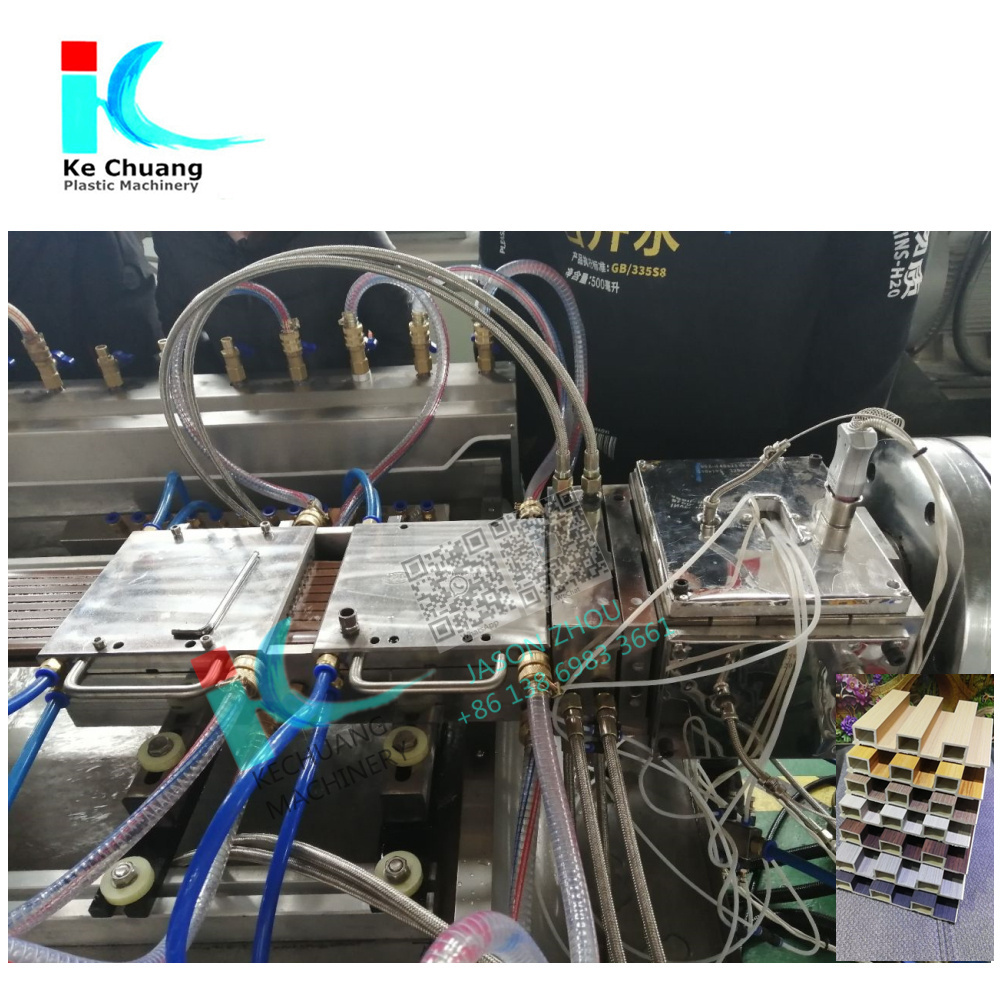

PVC profile extrusion line is mainly used to produce PVC window profiles, wide doors, elbowboards, multi-hole threading pipes(4-hole, 6-hole, 7-hole, 9-hole, etc). The line can adopt different twin screw extruders according to different profiles, sections and moulds, and also equip with vacuum forming table, haul-off machine, cutter, stacker or other auxiliary machines

II. Main models:

| Model | Max output(kg/h) | Production speed (m/min) | Power (kw) | Machine length(m) |

| SJSZ51 | 60-120 | 0.5-2 | 65 | 16 |

| SJSZ65 | 80-200 | 0.5-3 | 85 | 18 |

| SJSZ80 | 150-300 | 0.5-4 | 120 | 20 |

III. Advantages

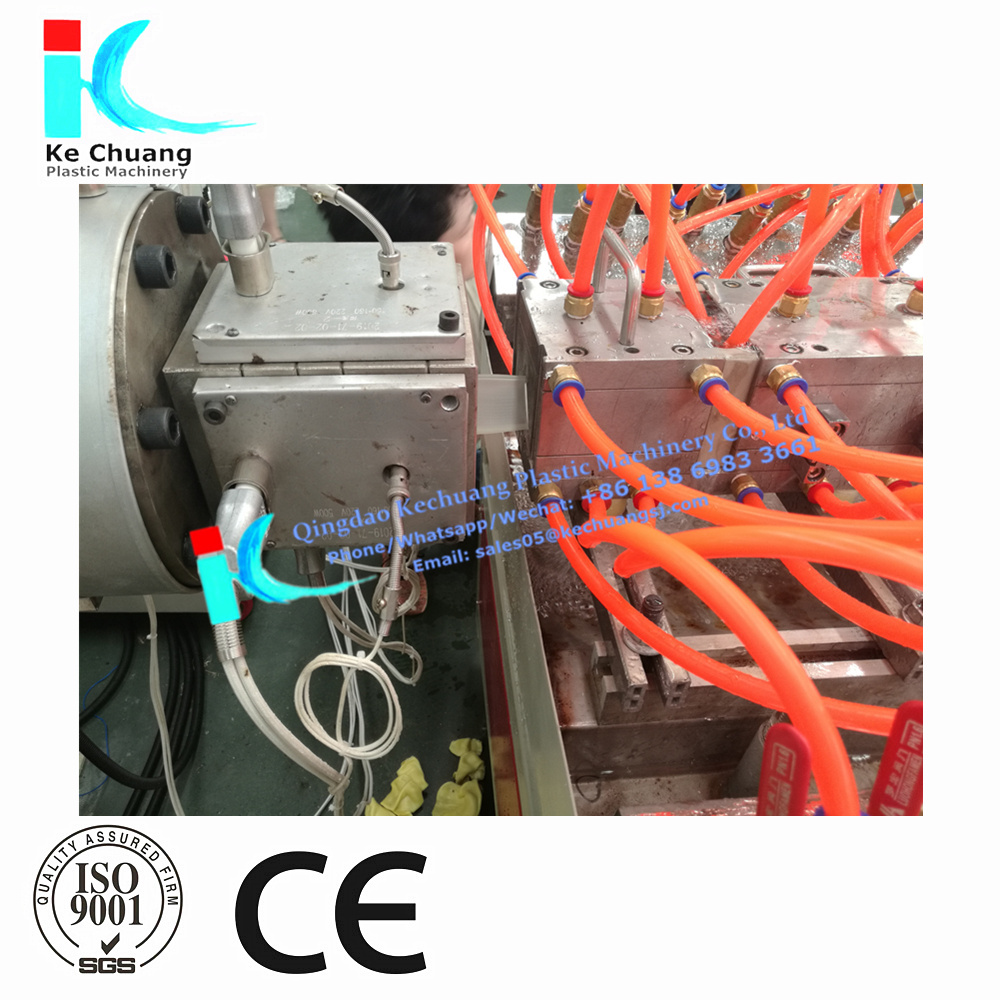

- High quality: Several patents, advanced design, all-around service, independent research team, and abundant experience in PVC/WPC.

- Official certificate: ISO9001/ CE certificate

- Long life time: Screws and machine barrels are made of high-quality materials and specially processed. The working life is up to 15,000 hours.

- Advanced control system: The production process can (be assured) rely on PLC control system and Omron sensors.

- Famous international accessories: Siemens, Omron, ABB, etc.

- Low energy consumption: our production line, compared with counterparts in China, can save up to 50% energy cost.

- Wide usage of raw materials: PP, PE, PVC, etc. Various wood powder and/or plant fiber.

- Excellent mixing ratio: Up to 70 percent of wood powder could be added, under the control of some special formula

IV. Applications

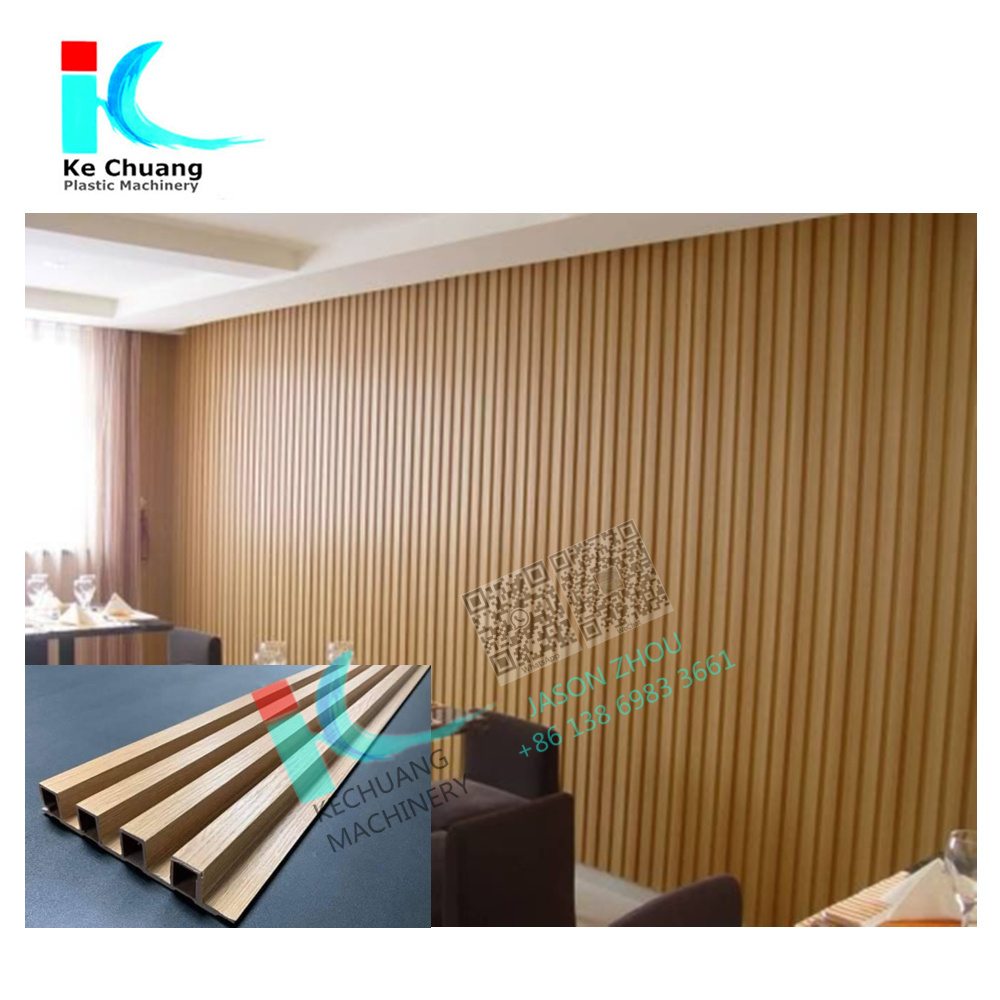

1. The finished product is mainly made from PVC, PE, PP wooden powder, cotton stalk, rice chaff and other natural fibers.

2. Plastic-wood compounded finished product is a new type of ideal environment-friendly material, which is made from PVC resin, polyolefin plastic and cellulose(straw, cotton stalk, wooden power, rice chaff, etc) with special procession and treatment.

3. It has such advantages as rot prevention, non-deformation, non-shading, pest resistant, fire-proof, split proof, etc.

4. It can be processed by a sawing machine or a planning machine.

5. It not only has natural properties of wood, but also has many colors for you to choose as per your demand.

6. It is widely used in making rail, passages, stairs, outdoor desk and chair, flower frame, pools etc. in addition, it can be used for indoor plate decoration , kitchen cabinet board, tray etc.

V. Main Machine pictures

VI. Final products

VII. Main electric components:

VII.

About KECHUANG:

KECHUANG Is a high-technique joint-stock company,which is relevant to high-molecule material,and engaged in developing,designing and manufacturing all kinds of plastic and mechanic.

Base on the developing tactic of “quality and credit make foundation stable,meanwhile,speed and technique create difference”, the company scale extends more and more large,and its technique power is more and\ more strong. The company has an independent studying & developing team,and cooperates with high education school during long time, the most competitive equipment is valued by all fields. Presently, the products of this company is popularly used all over the world,especialy export Russia, east-south Asian, middle-east and Africa, ect.