- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MCPT

-

Product name:

-

Locking Assembly Locking Device

-

Material:

-

Steel,Stainless Steel

-

Keyword:

-

Keyless locking device assembly elements

-

Standard:

-

GB ANSI DIN EN ISO

-

Size:

-

Standard Size or Customizesd Size

-

Customized:

-

Surpport OEM ODM

-

Feature:

-

Excellent Locking Performance ,Long Life

-

Surface Treatment:

-

Polishing

-

Type:

-

Standard

-

Usage:

-

Compact Keyless Connecting Decive

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining

-

Warranty:

-

1 year

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MCPT

-

Product name:

-

Locking Assembly Locking Device

-

Material:

-

Steel,Stainless Steel

-

Keyword:

-

Keyless locking device assembly elements

-

Standard:

-

GB ANSI DIN EN ISO

-

Size:

-

Standard Size or Customizesd Size

-

Customized:

-

Surpport OEM ODM

-

Feature:

-

Excellent Locking Performance ,Long Life

-

Surface Treatment:

-

Polishing

-

Type:

-

Standard

-

Usage:

-

Compact Keyless Connecting Decive

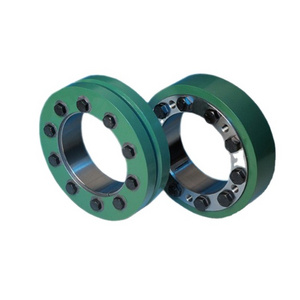

Product Description

Advantages of

Locking Assembly

:

1. Use

Locking Assembly

to make the manufacturing and installation of host parts simple. The machining of the shaft and hole for installing the expansion sleeve does not require high-precision manufacturing tolerances like interference fit. When installing the

Locking Assembly

, there is no need for heating, cooling, or pressurizing equipment. Simply tighten the bolts to the required torque. And it is easy to adjust, and the hub can be easily adjusted to the desired position on the shaft.

Locking Assembly

can also be used to connect parts with poor weldability.

2. The

Locking Assembly

has a long service life and high strength. The expansion sleeve relies on friction transmission, without weakening the keyway or relative movement of the connected parts, and will not cause wear during operation.

3. When overloaded, the

Locking Assembly

will lose its connection function and can protect the equipment from damage.

4. The

Locking Assembly

connection can withstand multiple loads, and its structure can be made into various styles. Depending on the installation load, multiple expansion sleeves can also be used in series.

5. The

Locking Assembly

is easy to disassemble and has good interchangeability. Due to the ability of the

Locking Assembly

to combine the shaft hub with a large fit gap, loosening the bolts during disassembly can make the connected parts easy to disassemble. When it is tightened, the contact surface is tightly fitted and not corroded, making it easy to disassemble.

Simple installation, long service life and high strength. When overloaded, the connection will be lost, which can protect the

equipment from damage, easy to disassemble, and has good interchangeability.

International standard clamp power locks, keyless locking device, Adjustable Locking Device, Safe Locking Device, Precision High Power Transmission Power Lock, Keyless shaft Locking Device, joint shaft axle wheel, auto universal joint, cross joint.

equipment from damage, easy to disassemble, and has good interchangeability.

International standard clamp power locks, keyless locking device, Adjustable Locking Device, Safe Locking Device, Precision High Power Transmission Power Lock, Keyless shaft Locking Device, joint shaft axle wheel, auto universal joint, cross joint.

Specification

|

Product name

|

Locking Device Locking Assembly

|

|

Material

|

Stainless steel ; Steel

|

|

Performance

|

high accuracy; Easy to install/adjust/disassemble; High strength,stable and reliable connection

|

|

Surface treatment |

|

|

Type

|

Z1, Z2, Z3, Z3 LONGER,Z4, Z5, Z6, Z7B, Z8, Z11, Z12A, Z13, Z14, Z19A,Z19B

|

|

Standard

|

GB ,ISO, DIN, ANSI, JIS, BS and Non-standard.

|

|

Usage

|

printing machine, cleaning machine, medical equipment, garden machine, construction machine, electric car, valve,

forklift, transportation equipment and various gear reducers.etc |

|

Applicable Industries

|

Machinery, industrial equipment, construction machinery, transmission equipment

|

|

Key words

|

Power Transmission Keyless locking device assembly elements

|

|

Service

|

OEM,ODM

|

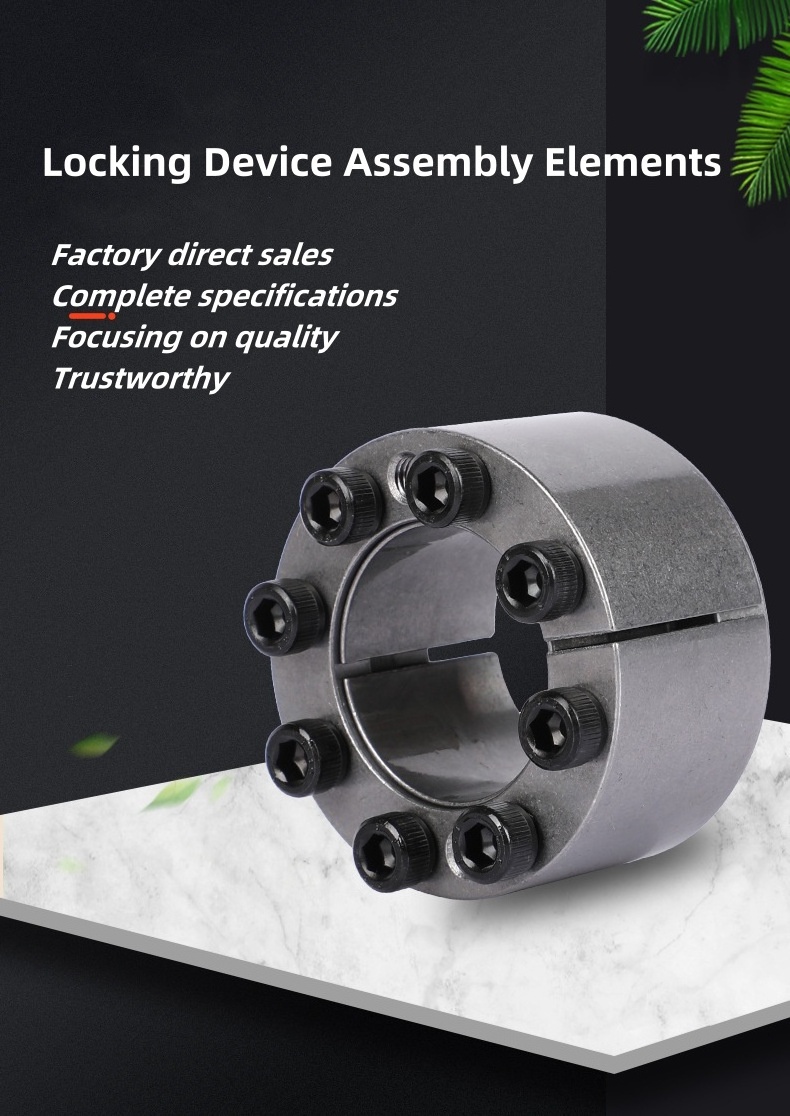

Instructions for installation and use of locking device assembly :

1. Installation

: The locking device assembly is coated with a layer of anti rust oil on its surface when leaving the factory. When installing the expansion sleeve, a layer of lubricating oil should also be applied to the installed parts (shaft and hub) (special attention: the lubricating oil applied should not contain substances such as molybdenum disulfide that significantly reduce the friction coefficient); Install the locking device assembly smoothly into the connection position, taking care to prevent tilting, and then tighten the bolts by hand in a diagonal crossing sequence. Set the torque wrench to 1/3Ts and tighten evenly in diagonal and cross sequence; Set the torque wrench to 1/2Ts and tighten evenly diagonally and crosswise. Set the

torque wrench to a torque value higher than Ts5% and tighten evenly in diagonal and cross sequence; Then tighten all bolts in a circumferential direction; Set the torque wrench to the Ts value to check if all bolts can still be tightened. If there are individual bolts that have not been locked, the above steps must be repeated.

2. Disassembly:

Before disassembly, loosen all bolts a few turns. Then remove some of the bolts and screw them into the disassembly screw holes. Cross tighten the screws diagonally until the inner and outer rings separate.

3. Protection:

During installation, prevent

locking device assembly

pollution and strictly use MOS2 oil. On machines operating in the open air or in poor working environments, rust proof grease should be regularly applied to the exposed end face and bolts of the expansion sleeve, and a form of expansion sleeve with good rust resistance should be selected. The expansion joint sleeve is a new and advanced mechanical basic component in modern times. It is a new type of keyless coupling device widely used internationally to achieve the connection between components and shafts. It achieves load transmission by tightening the pressure and friction generated between the containment surfaces by tightening the 12.9 grade high-strength screws. Compared with general interference connections and keyed connections, expansion sleeve connections have many unique advantages.

Applications

Packing & Delivery

Standard Package:Carton ,Wooden box or as your need. Efficient logistics delivery upon customer requirement, we can supply express

shipment, air shipment, truck shipment and sea shipment, etc.

shipment, air shipment, truck shipment and sea shipment, etc.

Hot Searches