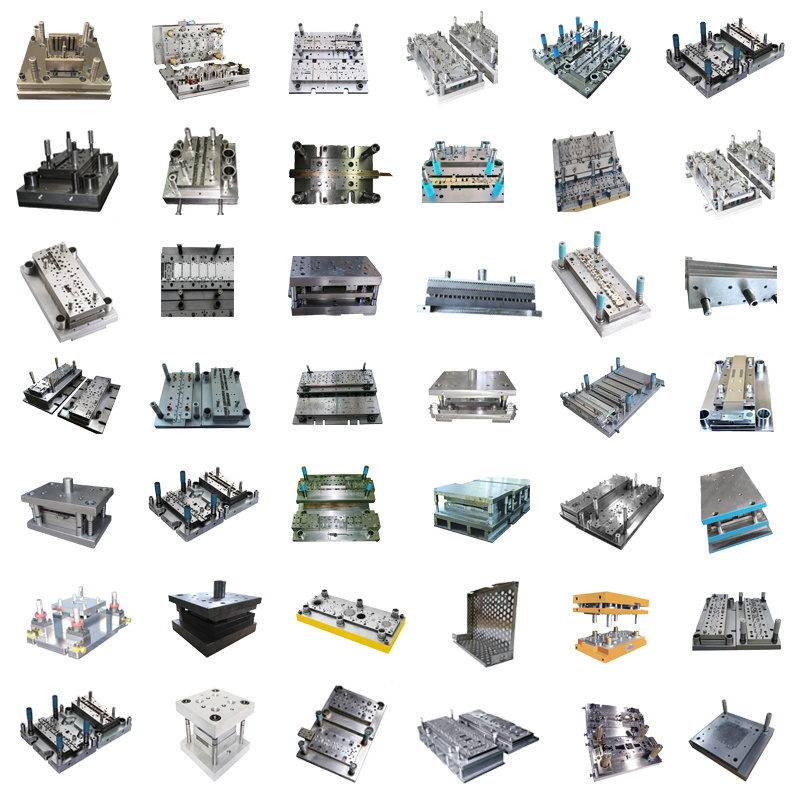

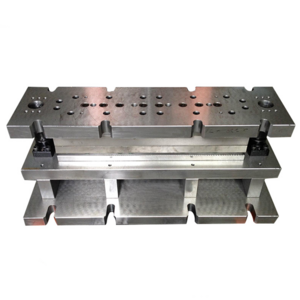

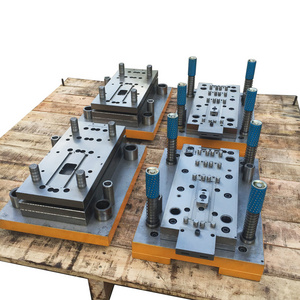

Three-day proofing saves mold opening12 hours expedited sampleTolerance up to 0.01mm

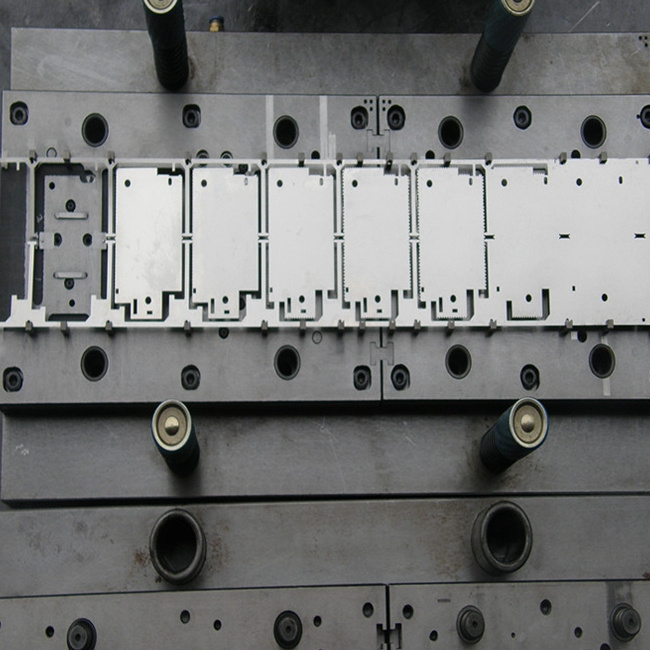

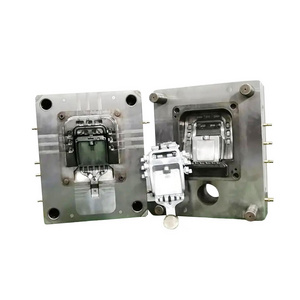

2.Intelligent Connector:

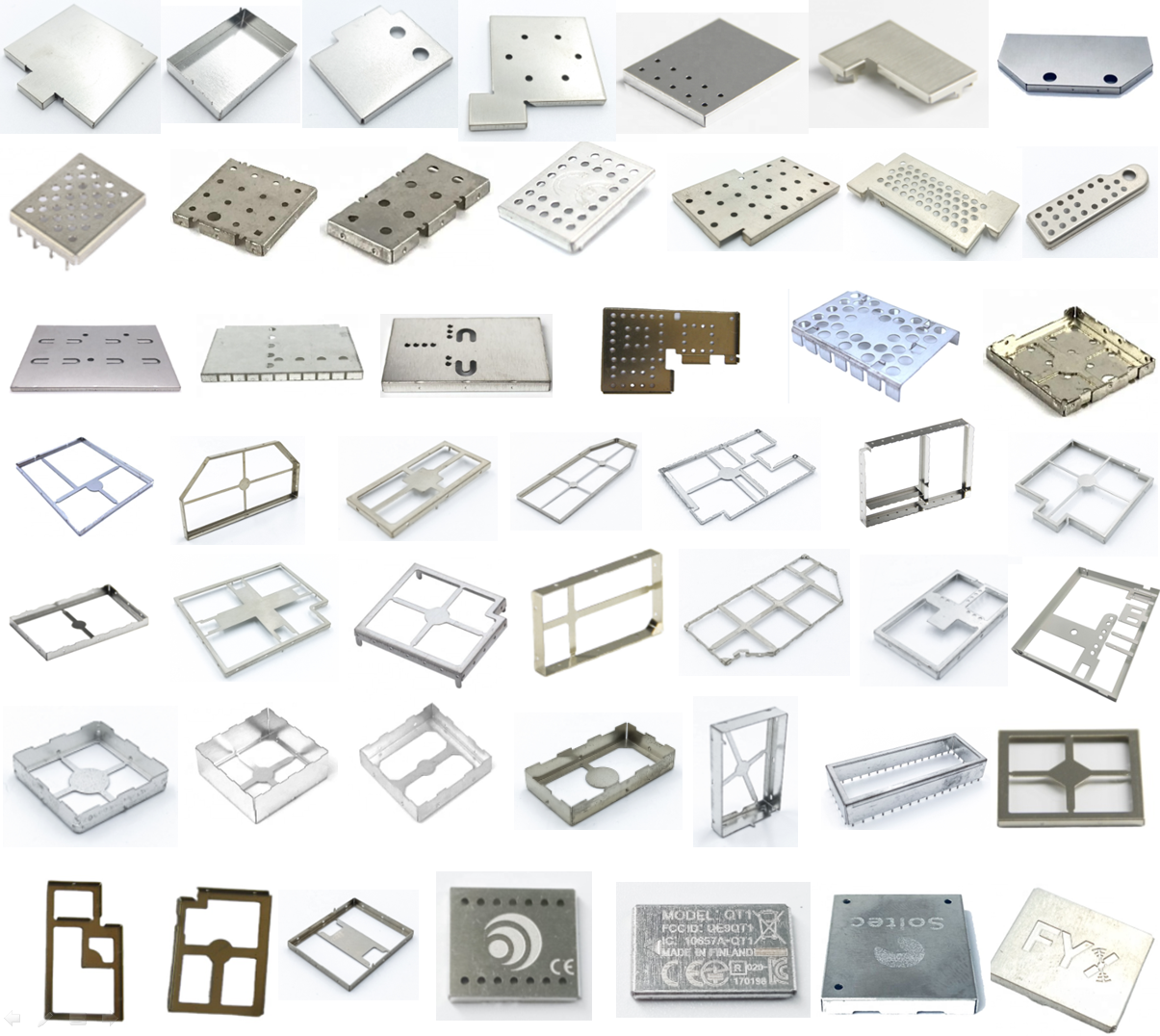

Imported Germany CNC MINI Bending MachineWorry-free customization of difficult non-standard partsMachinable thickness is 0.08-0.50mm.

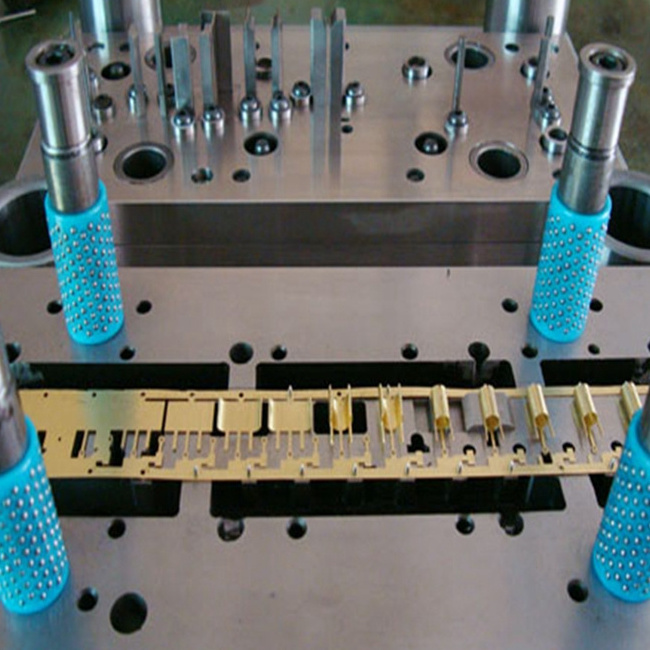

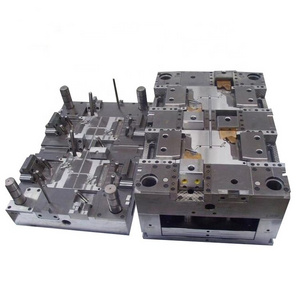

3.Precision Metal Shrapnel:

Life can reach more than 100,000 times. The number of mating cycles is more than 20,000Anti-oxidation/anti-fatigue/good rigidity/high precision.

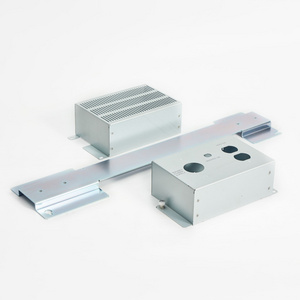

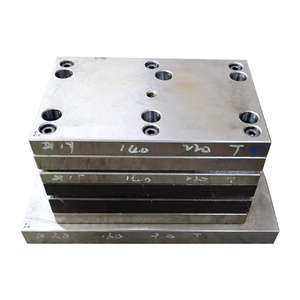

4.Precision Metal Bracket:

Three-day proofing saves mold opening12 hours expedited sampleTolerance up to 0.01mm

2.Intelligent Connector:

Imported Germany CNC MINI Bending MachineWorry-free customization of difficult non-standard partsMachinable thickness is 0.08-0.50mm.

3.Precision Metal Shrapnel:

Life can reach more than 100,000 times. The number of mating cycles is more than 20,000Anti-oxidation/anti-fatigue/good rigidity/high precision.

4.Precision Metal Bracket:

Three-day proofing saves mold opening12 hours expedited sampleTolerance up to 0.01mm