- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380V, 220V, 240V

-

Dimension(L*W*H):

-

different based on capacity

-

Weight:

-

3500 KG

-

Product name:

-

pp bag making machine

-

raw material:

-

polypropylene (pp) & high density polyethylene(HDPE)

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Online support

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Cement Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380V, 220V, 240V

-

Dimension(L*W*H):

-

different based on capacity

-

Weight:

-

3500 KG

-

Product name:

-

pp bag making machine

-

raw material:

-

polypropylene (pp) & high density polyethylene(HDPE)

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Online support

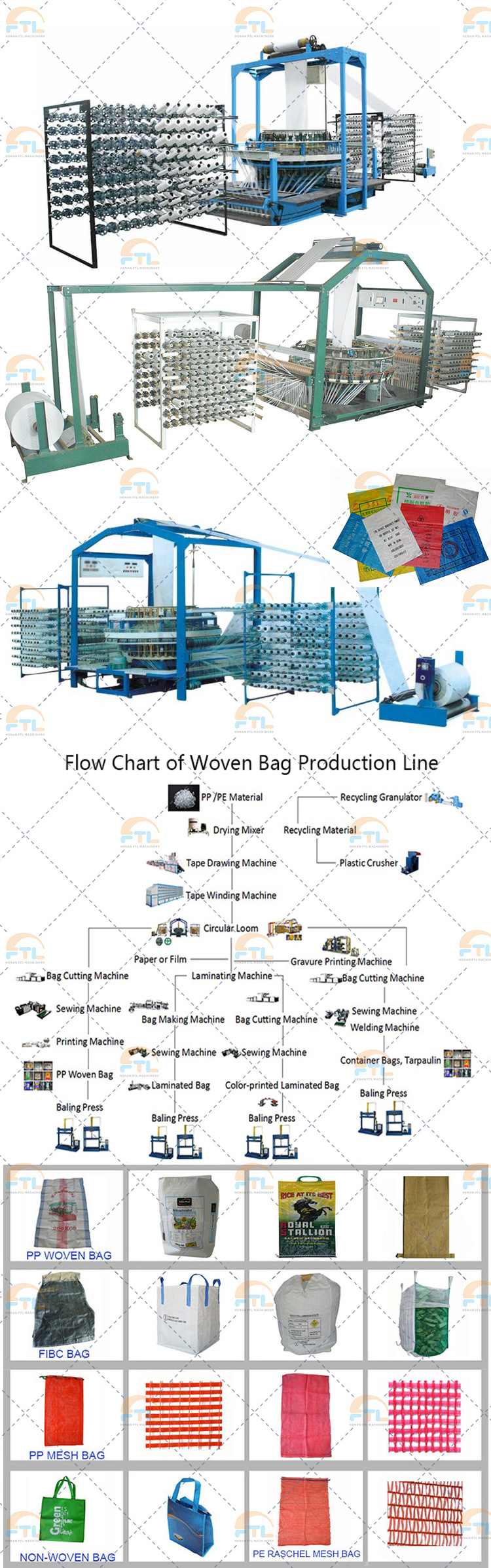

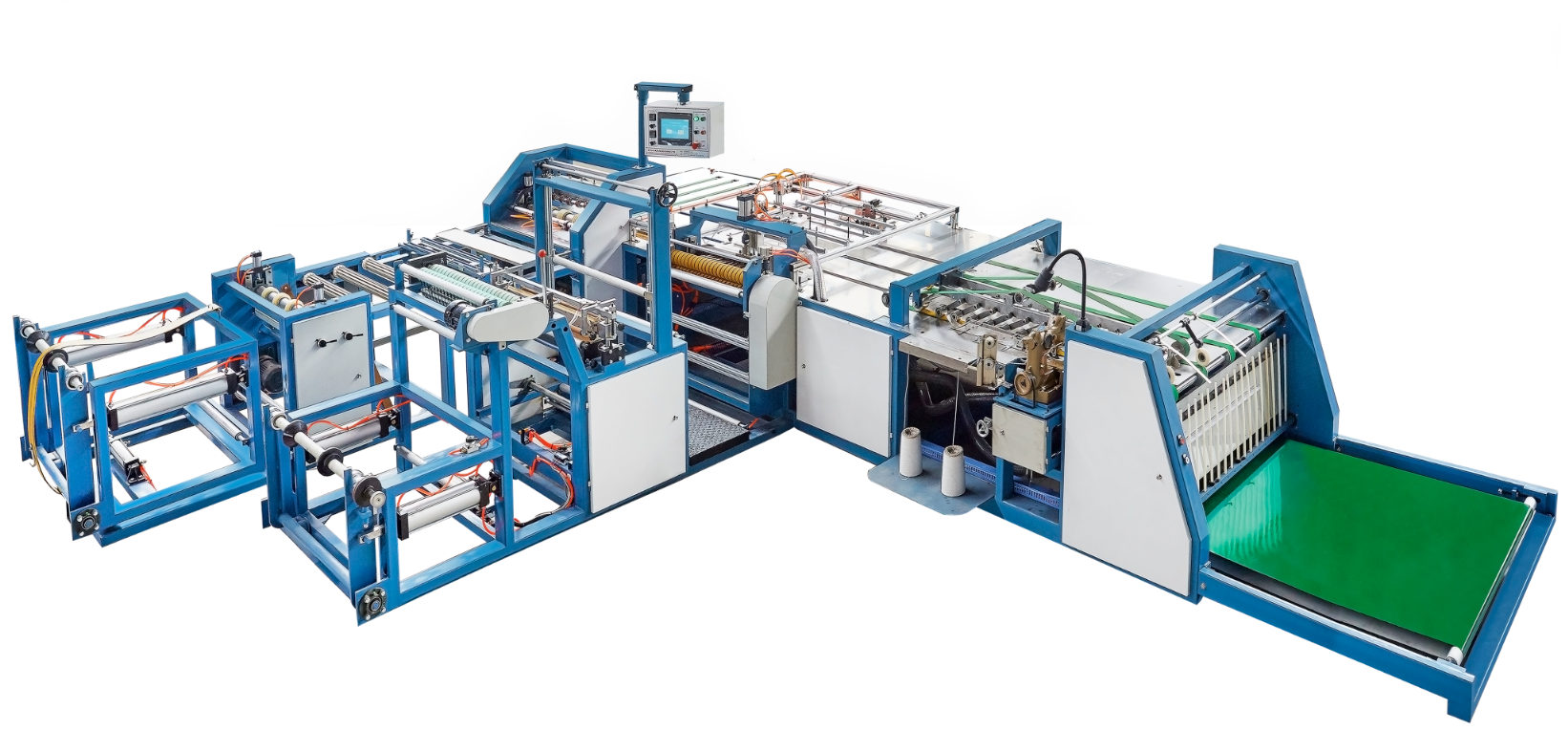

High speed automatic pp woven sack polythene rice bag making machine price

This pp woven bag production line is mainly used for producing PP woven bags for cement, rice, fertilizer, chemical mateials, animal feed and sugar etc.

It uses material of polypropylene (pp) & high density polyethylene(HDPE) for producing PP woven bag.It was designed and researched on the base of original circular loom, it is the substitute product of present common circular loom .

The main pp bag making machine used in the pp bag production line:

1. flat yarn extruder/plastic tape drawing machine and winding machine

The machine, using material of polypropylene and high density polyethylene, through heating, extruding and drawing, makes tape that is then winded for the weaving of the circular loom. Having been improved so many times, the machine can use 100% recycled PP and PE granules or powder to produce yarn.

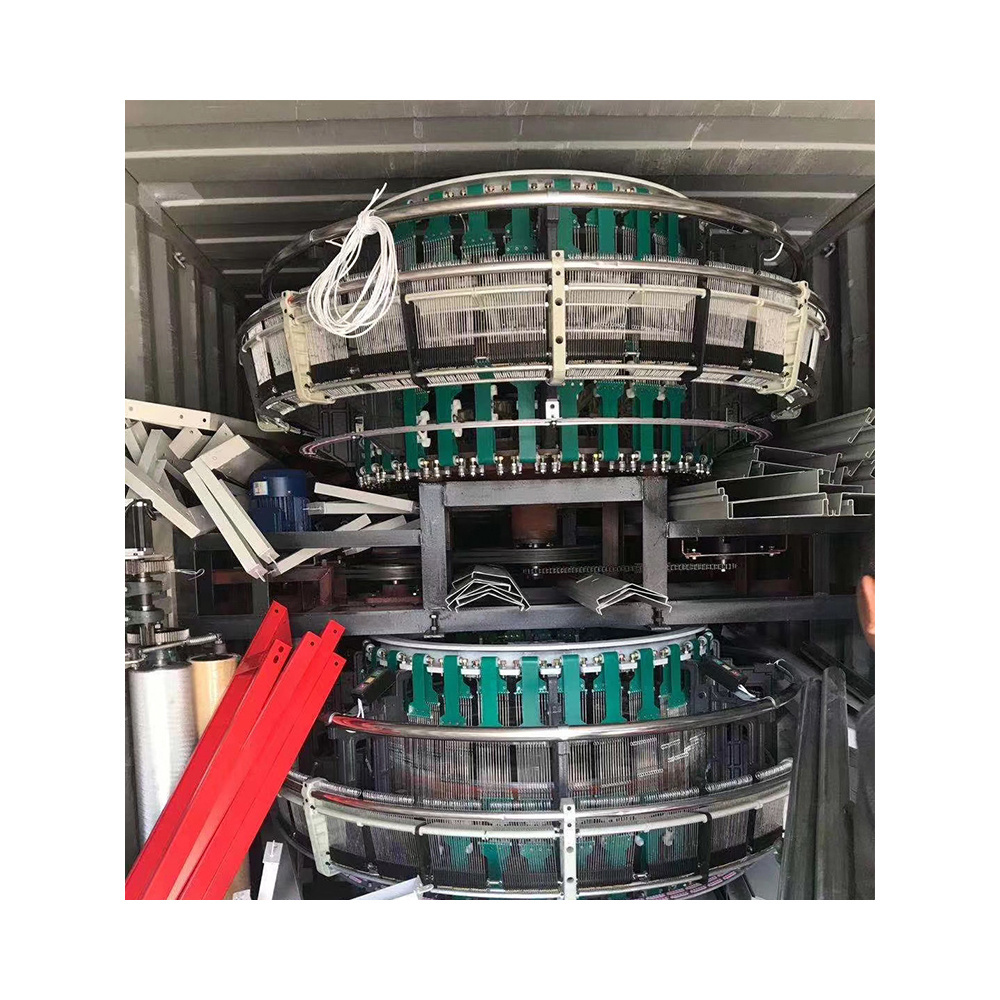

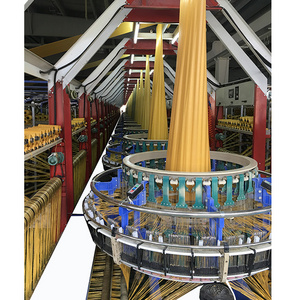

2. circular loom machine

We can make all type Circular Loom such as 4-shuttle Circular Loom, 6-Shuttle Circular Loom, 8-shuttle Circular Loom, and 10 shuttle Circular Loom. Circular Loom can make PP woven fabric for cement bag, rice bag, wheat Woven Bag , Jumbo/Container/FIBC Bags, sugar Woven Bags

| Type | ZD-PC-4/750 | S-YZJ-850/6S |

| Number of shuttle | 4 | 6 |

| Folding width of weaving (mm) | 350-750 | 350-850 |

| Max. number of warp | 768 | 720 |

| Rotational speed of main motor(r/min) | 140-180 | 120-180 |

| Production (m/min) | 1.4-1.8 | 1.8-2.7 |

| Output (pieces/year) | 500,000 | 700,000 |

| Power of main motor(kw) | 1.5/2.2 | 2.2/3 |

| Total power (kw) | 2/2.7 | 2.7/3.5 |

| Weight (About) (kg) | 1900 | 3000 |

| Installing dimensions (LXWXH) (mm) | 8300 X 2200 X 2730 | 9100X2410X3100 |

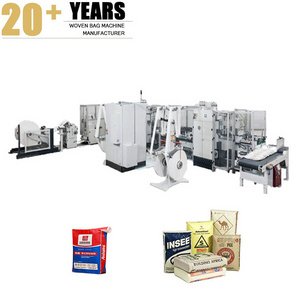

3. cutting and sewing machine

Product characteristics:

(1) Easy to operate rice sack making machine automatic pp woven bag cutting and sewing machine can automatically complete fixed length hot cutting, folding, bottom sewing and bagging of the woven barrel cloth to save labor;

(2) After hot-cutting, the bag does not adhere and opens easily.

(3) Easy to operate rice sack making machine automatic pp woven bag cutting and sewing machine can automatic counting, stackable feeding, adjustable quantity;

(4) Easy to operate rice sack making machine automatic pp woven bag cutting and sewing machine adopts PLC control, servo motor drive, accurate control of bag length;

(5) Easy to operate rice sack making machine automatic pp woven bag cutting and sewing machine can Pneumatic winding up, accurate photoelectric tracking edge rectification, easy operation, reliable quality, stable performance, low failure rate;

4. printing machine

5. packagind machine

PS: we also have lamination machine, different colors of printing machine, pp material reclycing machine, etc., all can be designed and supplied based on customers' detail requirement

More details about our machine:

Q 1. Are you manufacturer or trading company?

We are a specialized manufacturer.

Q

2

. Is your machine automatic or manual ?

Automatic.

Q

3

.

How do you control the quality?

Professional QC team comply with TQM insure you the quality. Each step is in compliance to the standards

.

At the same time

,

we will take photos or shoot video for you.

Q

4

. What about the service offered by company?

We have professional engineer

ing

team which can design and develop the mold to arrive different customer requirement.We will send technician to your country for installation and training make sure your worker can operate the machine well.We also have the sales team to offer good service from Pre-sale to After-sale.

Q 5. What is the machine warranty?

One Year.