Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CGFE

-

Voltage:

-

380V/220V/415V/440V

-

Dimension(L*W*H):

-

16m*2.5m*1.8m

-

Power (kW):

-

37

-

Weight:

-

7000 KG

-

Inverter:

-

ABB Brand

-

motor brand:

-

Siemens

-

speed of line:

-

0.5-6m/min

-

heater of barrel:

-

casting aluminum heater

-

heating area of barrel:

-

4 areas

-

mould:

-

die head+calibration mould

-

length of vacuum calibration table:

-

4m

-

haul-offs machine:

-

1.5kw with reducer

-

name:

-

pvc ceiling panel machine

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

65/132

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CGFE

-

Voltage:

-

380V/220V/415V/440V

-

Dimension(L*W*H):

-

16m*2.5m*1.8m

-

Power (kW):

-

37

-

Weight:

-

7000 KG

-

Inverter:

-

ABB Brand

-

motor brand:

-

Siemens

-

speed of line:

-

0.5-6m/min

-

heater of barrel:

-

casting aluminum heater

-

heating area of barrel:

-

4 areas

-

mould:

-

die head+calibration mould

-

length of vacuum calibration table:

-

4m

-

haul-offs machine:

-

1.5kw with reducer

-

name:

-

pvc ceiling panel machine

-

Marketing Type:

-

Ordinary Product

Overview

Products Description

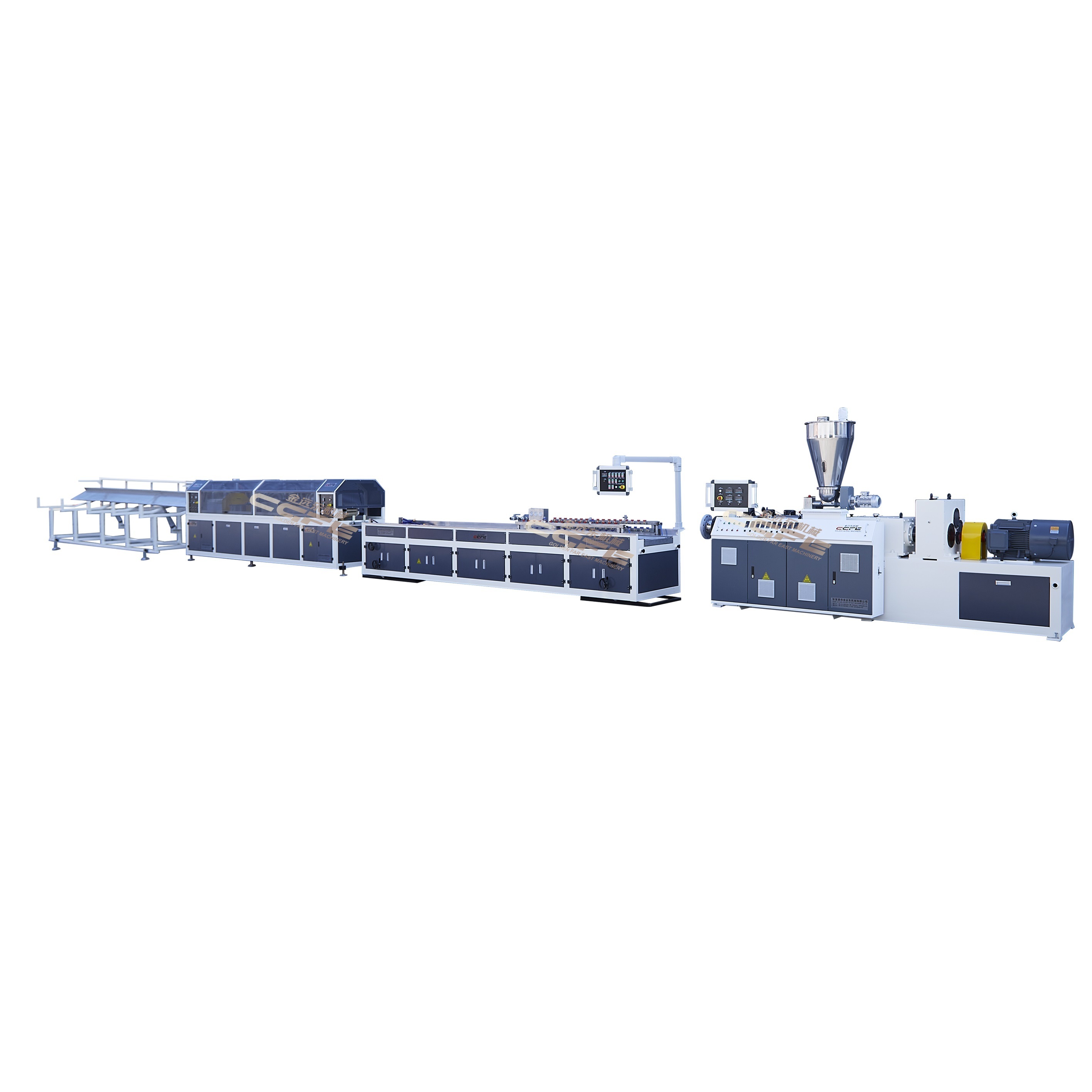

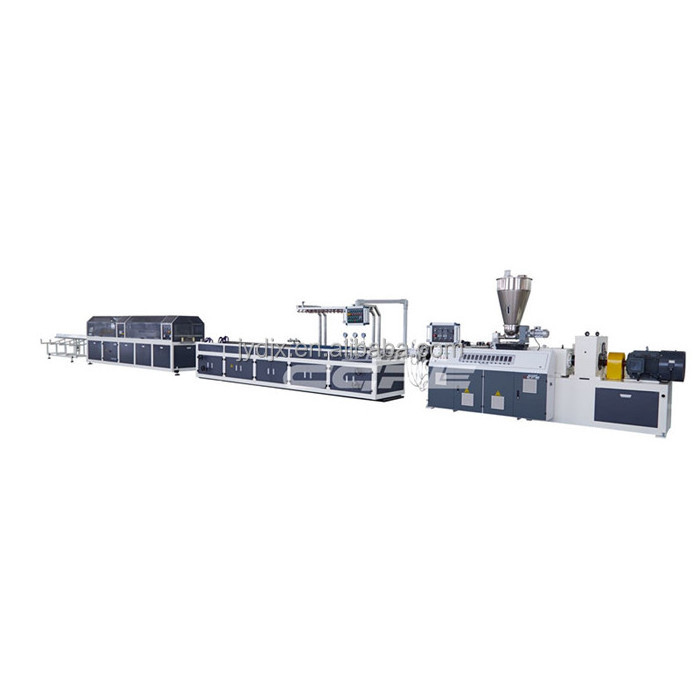

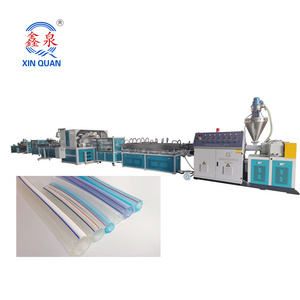

UPVC Ceiling Wall Panel Extrusion Line

Process Flow

Screw Loader for Mixer→ Mixing unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mould → Vacuum Calibration Table →Haul-off → Cutting → Final Product Inspecting &Packing

Details Images

Conical Twin Screw Extruder

--High specific output for gentle plastification of PVC material

--High melt homogenity even with high-filled material formulations

--Optimized material feeding system for stable production of PVC-U powder

--Bimetallic material screw and barrel ensuring long time working without trouble

--Suitable for PVC-U high-filled pipe production

--Output range from 150kg/h-900kg/h

--AC motor drive by inverter

--High melt homogenity even with high-filled material formulations

--Optimized material feeding system for stable production of PVC-U powder

--Bimetallic material screw and barrel ensuring long time working without trouble

--Suitable for PVC-U high-filled pipe production

--Output range from 150kg/h-900kg/h

--AC motor drive by inverter

--Vertical integrated structured gear box

Die head&Mould

--Complete set include extrusion die head, calibrator and cooling tank;

--Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

Vacuum Calibration Tank

--Include full set of vacuum and water pump

--Length from 4m-11.5m

--Independent operation panel for easy operation.

--Independent operation panel for easy operation.

Haul-offs&Cutting Machine

--Upper and lower caterpillar is driven separately and speed control by frequency inverter;

--Fast change type pads for easy operation;

--Install plate is adopts aluminum material;

--Compacting driving by pneumatic;

--Install plate is adopts aluminum material;

--Compacting driving by pneumatic;

--Tracking cutter or lifting saw cutter with adopts double station dust collection system;

--Synchronous driving by air cylinder or servo motor control.

--Synchronous driving by air cylinder or servo motor control.

Stacker

--Stainless steel304 as touching material;

--Discharge driving by air cylinder.

Main Models of Extruder

|

Model

|

Power(Kw)

|

Screw Diameter(mm)

|

Output(Kg/h)

|

Dimension(mm)

|

|

SJZ51/105

|

15

|

ø51/105

|

80

|

3600*2300*2260

|

|

SJZ55/110

|

22

|

ø55/110

|

150

|

3800*2300*2260

|

|

SJZ65/132

|

37

|

ø65/132

|

250

|

4350*1500*2360

|

|

SJZ80/156

|

55

|

ø80/156

|

400

|

5150*1500*2460

|

|

SJZ92/188

|

110

|

ø92/188

|

800

|

6725*1550*2814

|

Certificate

Technology cooperation

Conical Twin Screw Extruder

Screw and Barrel Material 38CrMoAlA,Nitriding,

Nitriding Layer Thickness:0.5~0.7mm,

Surface Rigidity:800~900HV

Surface Rigidity:800~900HV

Counter rotation, turning outside

ABB Inverter

High efficiency of speed regulation, belongs to the high efficiency of speed regulation method

High response

High stability

Siemens Motor

Outstanding rotor machining technology

High-performance protection class

Robust component connections

High reliability and long service life

Our Company

Golden Far East Machinery Co., ltd. is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines. It is located in the beautiful port city of Zhangjiagang with convenient traffic; it's about 150 km away from Shanghai.

Our products include single screw extruder, twin screw extruder, PVC/HDPE/PP-R pipe extrusion line, PVC profile extrusion line,

WPC profile extruding line, high speed mixer and plastic sheet production lines with the relative plastic auxiliary machine, etc.

Our products have been exported to Egypt, Uzbekistan, Brazil, Turkey, Russia, UAE, Thailand, Italy, etc.

WPC profile extruding line, high speed mixer and plastic sheet production lines with the relative plastic auxiliary machine, etc.

Our products have been exported to Egypt, Uzbekistan, Brazil, Turkey, Russia, UAE, Thailand, Italy, etc.

Exhibition

2023 Saudi Arabia PLAST

2023 CHINA PLAST

2024 BANGLADESH IPF

Contact us

FAQ

1.Your company is a trading company or a direct factory?

We are a direct factory located in Zhangjiagang City. Very close to Shanghai and Wuxi (airport and train provided). If you

arrive in Shanghai or Wuxi, we can pick you up to visit our factory.

We are a direct factory located in Zhangjiagang City. Very close to Shanghai and Wuxi (airport and train provided). If you

arrive in Shanghai or Wuxi, we can pick you up to visit our factory.

2.If we buy your machine, what is your guarantee or guarantee of quality?

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

(1) Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

(2) Through the letter of credit, you can easily lock the delivery time.

(3) After visiting the factory, you can ensure the authenticity of our bank account.

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

(1) Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

(2) Through the letter of credit, you can easily lock the delivery time.

(3) After visiting the factory, you can ensure the authenticity of our bank account.

4. How to ensure the quality of machine?

(1) In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have accumulated professional processing methods in the past few years.

(2) Each component before assembly needs to be strictly controlled by inspectors.

(3) After all equipment is completed, we will connect all machines and run the entire production line in our company before shipping to ensure the stable operation.

(1) In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have accumulated professional processing methods in the past few years.

(2) Each component before assembly needs to be strictly controlled by inspectors.

(3) After all equipment is completed, we will connect all machines and run the entire production line in our company before shipping to ensure the stable operation.

Hot Searches