- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZHIXIN

-

Voltage:

-

380v/220v

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

2300*2200*2100mm

-

Weight:

-

2000 kg

-

Product name:

-

Automatic Paper Lunch Box Making Machine

-

Finished Products:

-

Lunch Food Box

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Function:

-

AUTOMATIC FORMING

-

Usage:

-

Food Packing

-

Papar Grammage:

-

200-620g

-

Paper Thickness:

-

≤1.6mm

-

Take Away Box:

-

Max 530*530, Min 263*263

-

Burger Box:

-

Max 376*262, Min 250*140

-

Tray Box:

-

Max 290*210, Min 164*107

Quick Details

-

Production Capacity:

-

180pcs/min

-

Product Type:

-

Paper Lunch Box Machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZHIXIN

-

Voltage:

-

380v/220v

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

2300*2200*2100mm

-

Weight:

-

2000 kg

-

Product name:

-

Automatic Paper Lunch Box Making Machine

-

Finished Products:

-

Lunch Food Box

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Function:

-

AUTOMATIC FORMING

-

Usage:

-

Food Packing

-

Papar Grammage:

-

200-620g

-

Paper Thickness:

-

≤1.6mm

-

Take Away Box:

-

Max 530*530, Min 263*263

-

Burger Box:

-

Max 376*262, Min 250*140

-

Tray Box:

-

Max 290*210, Min 164*107

Product Description

Machine Description

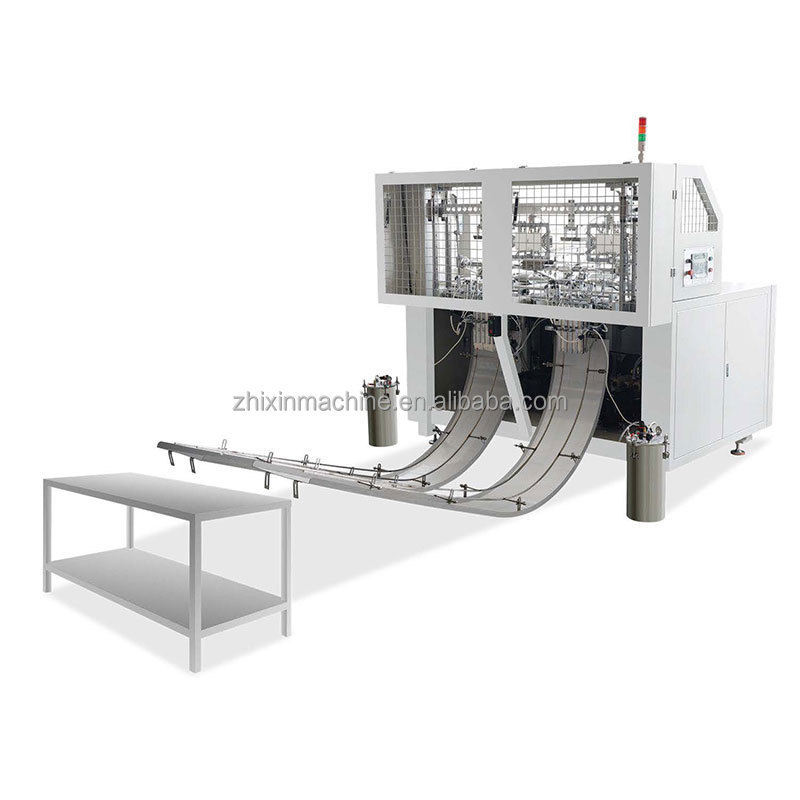

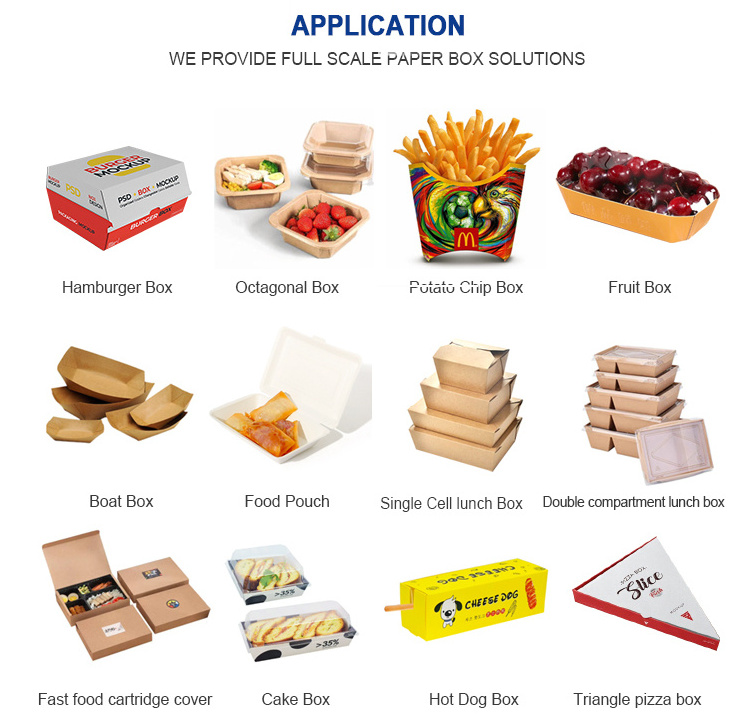

Carton Erecting Machine (paper box forming machine) is an automatic machine, specialized in making food carton, box, container which are made from cardboard, paper, paperboard, corrugated paper etc.

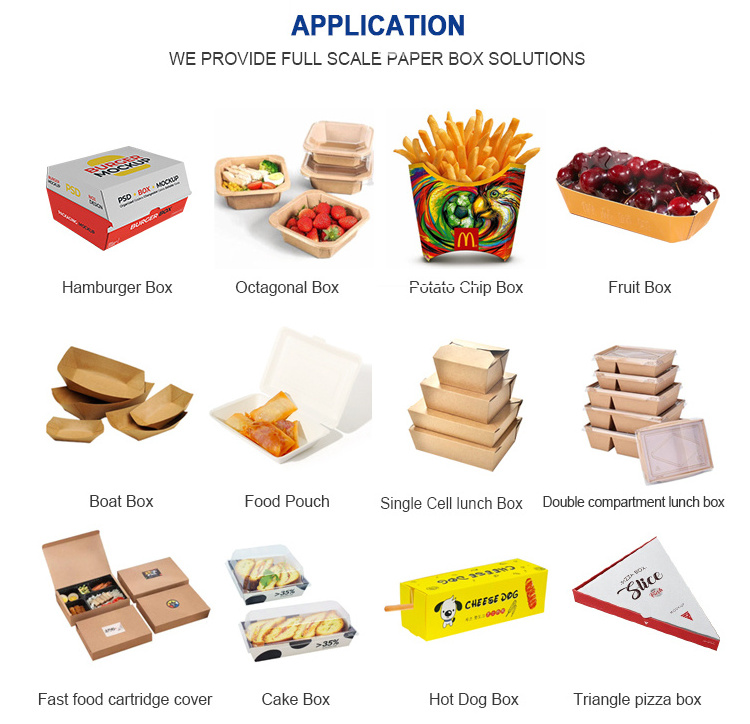

The food box (carton, container, dish, tray) is widely used as burger box, hot-dog box (tray), one block box, food pail box

(Chinese food box, take-away box), fries box (chips box, chips tray), lunch box, meal box, etc.

The food box (carton, container, dish, tray) is widely used as burger box, hot-dog box (tray), one block box, food pail box

(Chinese food box, take-away box), fries box (chips box, chips tray), lunch box, meal box, etc.

|

Model

|

ZX-2000

|

|

|

|

Paper Weight

|

200-620g

|

|

|

|

Speed

|

180pcs/min(one station)

|

|

|

|

Material

|

200-620gsm

Corrugating paper thick:1.6mm

|

|

|

|

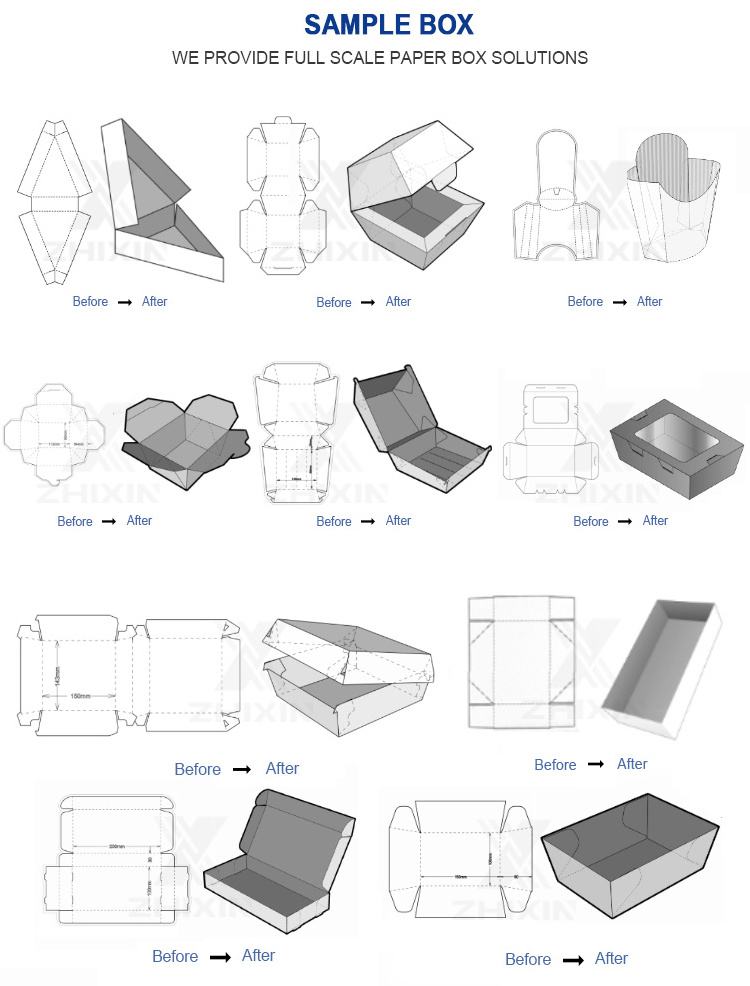

Box Size

|

Length

|

L 100-450mm

|

|

|

|

|

Degree:5°-45°

|

|

|

|

Width

|

W 100-600mm

|

|

|

|

Height

|

H 15-200mm

|

|

|

Paper Thickness

|

≤1.6mm

|

|

|

|

Machine Size

|

2300*2200*2100mm

|

|

|

|

Take Away Box

|

Max 530*530, Min 263*263

|

|

|

|

Burger Box

|

Max 376*262, Min 250*140

|

|

|

|

Tray Box

|

Max 290*210, Min 164*107

|

|

|

|

Voltage

|

380v/220v

|

|

|

|

Current

|

50hz

|

|

|

|

Power

|

6.5kw

|

|

|

|

Air Requirement

|

0.5Mpa, 0.4cube/min

|

|

|

|

Power Source

|

380V/220V

|

|

|

|

Weight

|

2000kg

|

|

|

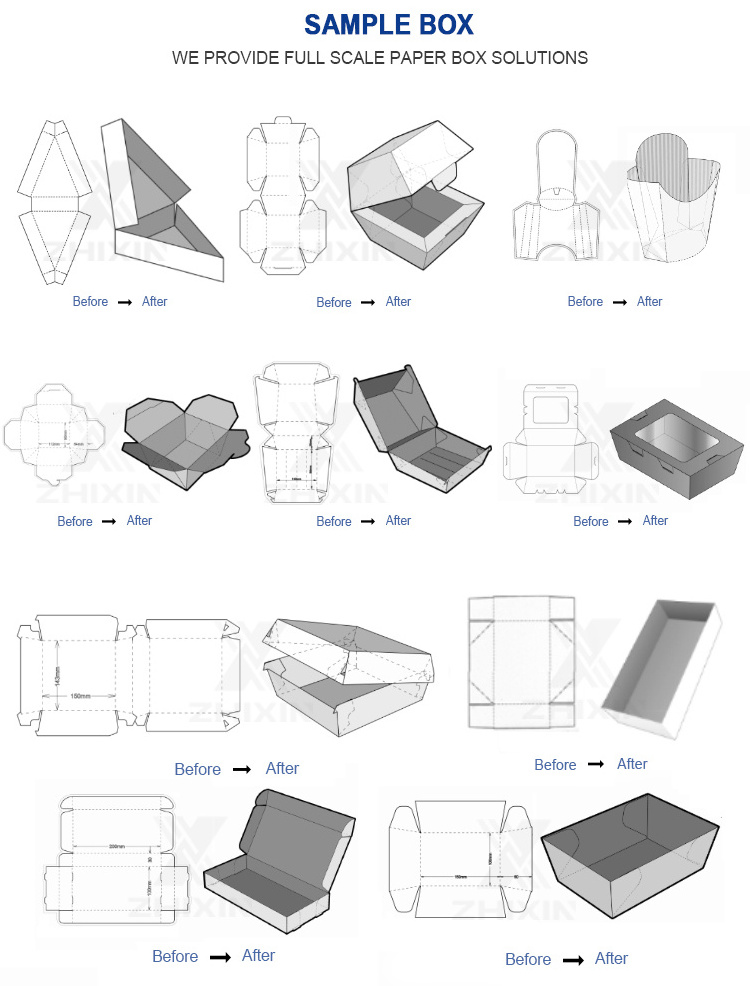

Basic Paper Box Shape

Comparison with others - Multi Advantages

Discharging part

The paper is conveyed forward through the control of the cylinder, and the pressure plate is controlled by the pedal to replenish the material to achieve a non-stop state.

Collection department

The product is compressed and shaped by the mold

Paper suction part

Through the up and down movement of the swing arm, the suction nozzle of the machine sucks the paper into the mold from the discharge place.

Safety window

protect the operator from injury when the machine is in operation

Swing arm part

control suction nozzle part suction paper and mold pressing

Electric cabinet

control the data of each motor and servo of the machine, the main electrical appliances are controlled by Schneider

Counter

How many quantities can be programmed as a unit.

Transport track

Let the product be transported neatly, the size of the product is fixed by the fixing rods on both sides, and the packaging is more convenient.

Gluing parts

The carton is placed under the mold through the suction nozzle and the corresponding corners are glued.

Suction nozzle

Suck the carton by the suction force generated by the air pressure of the cylinder.

Hot Searches

![[JT-HBJ-D1200]High Speed Paper Lunch Burger Box Making Machine Automatic Paper Carton Erecting Forming Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/c03ecce756e6393ea2c682c55040c312.jpg!/rotate/180/sq/300)