- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fuyuan, Fuyuan

-

Voltage:

-

220-380v

-

Power:

-

20kw

-

Dimension(L*W*H):

-

4500MM*1500MM*2200MM

-

Weight:

-

3500 kg

-

Product name:

-

Paper Tube Making Machine

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and tra

-

Paper tube layers:

-

3-16 layers

-

Tube thickness:

-

3-15 mm

-

Tube inner diameter:

-

20 - 100mm

-

Paper gramme:

-

150-550gsm

Quick Details

-

Production Capacity:

-

300sets/month

-

Product Type:

-

Paper Tube Making Machine, Paper Core Machine, Paper tube machine

-

Place of Origin:

-

Henan, China, China (Mainland)

-

Brand Name:

-

Fuyuan, Fuyuan

-

Voltage:

-

220-380v

-

Power:

-

20kw

-

Dimension(L*W*H):

-

4500MM*1500MM*2200MM

-

Weight:

-

3500 kg

-

Product name:

-

Paper Tube Making Machine

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and tra

-

Paper tube layers:

-

3-16 layers

-

Tube thickness:

-

3-15 mm

-

Tube inner diameter:

-

20 - 100mm

-

Paper gramme:

-

150-550gsm

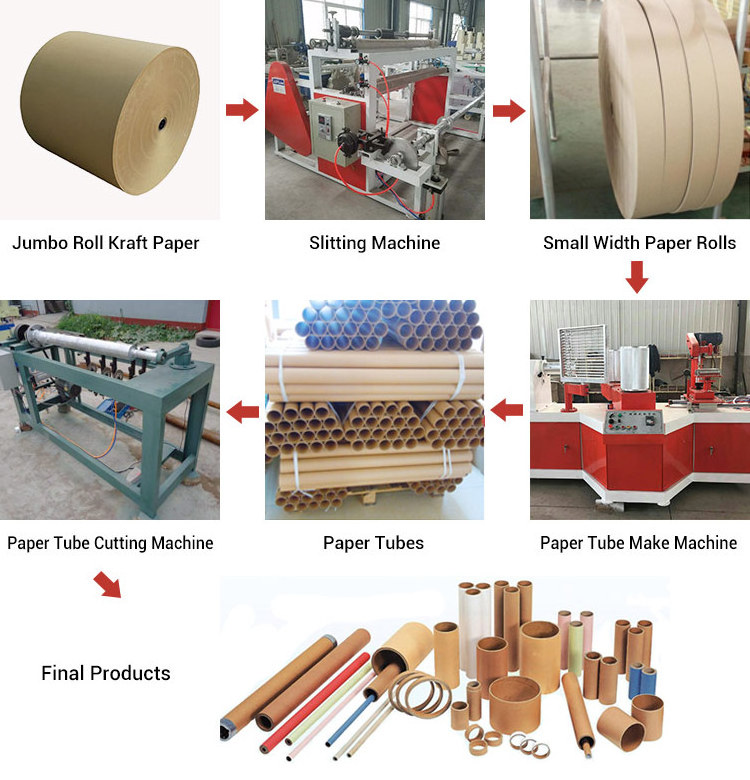

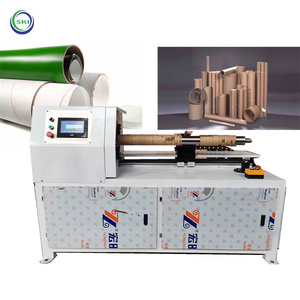

Automatic paper core tube making and cutting machine

This kind of paper core machine is mainly used for making paper tube. The tubes made can be used as core of toilet paper roll. We have different model of paper core machine for choice,

can make paper tube with different diameter and thickness. The finished tube can be cut and discharged automatically. Infrared and automatic transmission make cutting length more accurate. paper tube making machine , paper core making machine ,paper tube machine

Main Characterstic

--Adopt thick steel plate to ensure the tenacity and low vibration.

--Adopt the vector-type and high-torque frequency control.

--Adopt the CNC Synchronous cutting system.The cutting stand is driving by the precise ball

screw and servo motor.

--Pulse fixed-length control to ensure the consistency of cutting length in different operating

speed of the main machine.

--PLC control system is adopted to improve the cutting response speed and ensure the

accurate control of cutting length.

-- Adopt new type operation panel and big size color touch screen.

-- Adopt Multi-function bottom paper supply device and the infrared hunting gear to make the

machine automatically shut-down if it breaks or loses paper.

-- Linkage integer with all-electric control including whole paper supply rack , gumming rack

and paper guide device.

-- Adopt Modular electrical layout design to follow the maintenance accessibility .

| Machine Type | FY-2150B | FY-4150B |

| Tube Layer | 3~16 | 3~21 |

| Tube Diameter | 20~150mm | 40~250mm |

| Tube Thickness | 0.5~8mm | 1~15mm |

| Cutting Method | Single Round Knife Cutting Without Resistance | |

| Gluing Method | Single/Double Side Gluing | |

| Working Speed | 3~20m/min | |

| Control System | Variable Frequency Speed Control | |

| Main Power | 5.5KW | 11KW |

| Dimension | 3200mm*2000mm*1950mm | 3800mm*2000mm*1950mm |

| Weight | 2800kg | 3500kg |

| Warranty | One Year & Long-term Technical Service | |

About the packaging of our Paper Tube Making Machine machine, we have standard export package or we also can package the goods by customer's requirements.

As for the shipping of our egg tray machine, we can delivery the goods by air, by sea and so on.

Pre-sales

1.Online all day, to ensure that all your questions are answered within two hours;

2.Give you professional advice and recommend the machine that suits you;

3.Arrange the time and invite you to visit our factory;

On-sales

1. one stop service

We provide one stop service.

a. Because we are a factory with more than 30 years of experience in the production of rewinding machines, we have a more competitive price and quality can be guaranteed;

b. We have a very reliable freight forwarding company, and the delivery period is controllable;

c. We have a professional engineer team for your instalation and worker traning.

2. customized service

All machines can be customized, like color, embossing, jumbo roll core diameter.

After-sales

One year warranty, we provide free machine parts within one year.

Any question you can tell us if you have when operate the machine.

1.How about your machine quality, we are worry about the quality?

A:

First, we have 33 years’ experience in manufacturing toilet tissue paper roll machine.

Our company have International Quality System certificate as well as production capacity We use good material, production of high quality machines, and reasonable prices. You get what you pay for.

2.How do you make your price?

A:

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.

You will get competitive price and better quality.

3.How to operate and maintain the machine?

First, we will provide a professional and detailed user guide to you with the machine;

Second, we will debug the machine in the best status for you; At last, we also provide abroad technical training service.

4.what kind of after sales service will you offer to us?

A:

For the first year, if any quality problem, we will send you the new part by free, after first year, we will provide after-sale service and technical support for the machine in lifetime, and support you with easy damaged parts with manufacturing cost.

Other recommend machine

paper straw making machine , the diameter is 5-10mm

paper cup making machine