- Product Details

- {{item.text}}

Quick Details

-

water reducing rate:

-

38%-40%

-

solid content:

-

40% 50%

-

Function:

-

high water reducer rate,good slump retaining ability ,high strength

-

Advantage:

-

the 3rd generation Concrete cement additive

Quick Details

-

Place of Origin:

-

Hebei, China

-

Apperance:

-

Light yellow oily liquid with slight odor

-

Application:

-

Ready mixed concrete

-

water reducing rate:

-

38%-40%

-

solid content:

-

40% 50%

-

Function:

-

high water reducer rate,good slump retaining ability ,high strength

-

Advantage:

-

the 3rd generation Concrete cement additive

Product name: Polycarboxylate Superplasticizer PCE 50% Concrete Admixture

Polycarboxylate superplasticizer is A New Generation Hign Performance superplasticizer based On polycarboxyla tetechnology

Advantages:

1, High Water Reduction : The Water Reduction Rate Of Concrete Is Above 29%-38%

2, High Slump Retention Ability :delay Time Of Transporting Concrete And Time Of Detention At Construction Site

3, Excellent Workability .High Fluidity,Easily Deposing And Compacting.Make Concrete Reducing Viscosity,Without Bleeding And Segregation, Easily Pumping.

4, Wide Adaptability :It Is Compatible With Ordinary Silicate Cement, Silicate Cement, Slag Silicate Cement And All Kinds Of Blendings Having Excellent Dispersibility And Plasticity

5, Excellent Durability : Low Lacunarate,Low Alkali And Chlorin-Ion Content. Enhancing Concrete Strength And Durability

6, Environmental Friendly Products : No Pollution During Production

1.Widly Used In High Strength Concrete For Railway, Haven, Traffic, Bridge And Electric Power.

2.It Is Excellent Superplasticizer In Premix Of Construction And Cast-In-Place Concrete.

3.Is Especially Suitable For The Preparation Of High Strength, High Durability Self-Compacting, Steel Fiber And Self-Leveling Concrete.

|

Items |

Specification |

|

Visual Appearance |

Lightyellow Viscous Liquid |

|

Density (G/Cm3,23°C) |

1.10±0.02 |

|

PH (23°C) |

6.0-8.0 |

|

Solid Content (%) |

40±1.0 |

|

Cl(%) |

≤0.3 |

|

Na2SO4 (%) |

≤0.2 |

|

Alkali(Na2O+0.658 K2O), % |

≤5 |

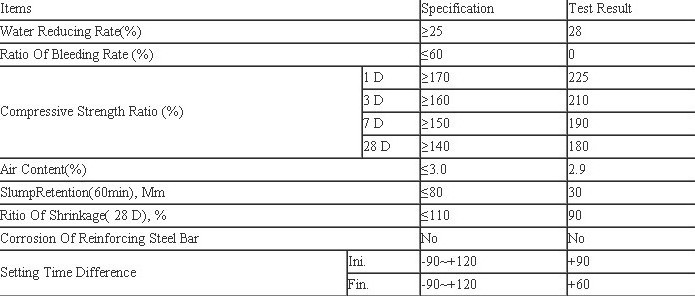

According to China National Standard Method P.O.42.5 Standard Cement, Dosage is 0.55% By Wt Of Cement

1,The Recommeded Range Of Dosage (Wt.% Of Cement):0.5%-1.6%.

2,It Can Be Mixed In Metric Water Or Added In Concrete Mixer.The Recommended Stirring Time Is 150s At Least. Concrete Mixing Test Should Be Made Before Using In Order To Insure Concrete Quality.

3,Can Be Compounded Together Retarder, Defoamer, Air-Entertraing Reagent,Lignin Sulfonic Natrium and So on

4It Is Not Suggested To Use Products Directly In Concrete Or Other Materials Without Formulation Blending. The Compatibility Of Products To Particular Cement, Aggregate And The Other Raw Materials In The Application Is Not Guaranteed. It Should Be Obtained Through Trial Mixes And Formulation Technologies By The Users.

220kg/ plastic Drum,17.6tons/20'FCL Or 1000kg/ IBC Tank And 23mt Flexitank

It Shall Be Kept From Direst Sunlight And Stored In Dry And Cool Place At The 0-35°C.

Shelf Life :

Its Shelf Life Is Normally Six Month. It Is Tested Eligibility And Then Used When It Is Exceeded.

Handling:

Keep Container Closed When It Is Not In Use. Do Not Store The Product Directly Under Sunlight.

-

Company introduction

-

Horizon Admixtures is a Professional manufacture of Concret admixtures- HPEG TPEG APEG and polycarboxylate superplasticizer PCE ; Cement grinding aid(CGA) raw material TIPA DEIPA

-

Sell PCE HPEG TPEG Process

-

DCS Automation Control in production line; H ightech new enterprises , own ing one invention patents and number s of patented technology

-

22 years production history;ISO &SGS approved plant, Free sample will be send