- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E2

-

Place of Origin:

-

Hung Yen, Vietnam

-

Brand Name:

-

TTP _ Plywood

-

Model Number:

-

TTP-LVL

-

Size:

-

Cutting size

-

Thickness:

-

14mm ~ 40mm

-

Moisture content:

-

Below 15%

-

Glue:

-

E2 - E0

-

Core:

-

Pine

-

Moisture:

-

12%

-

MOQ:

-

1x40HQ

-

Density:

-

500-600kg/m3

-

Delivery time:

-

Within 15 Days

-

Packing:

-

Pallet Packing

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

total solution for projects, Others

-

Application:

-

Outdoor

-

Formaldehyde Emission Standards:

-

E2

-

Place of Origin:

-

Hung Yen, Vietnam

-

Brand Name:

-

TTP _ Plywood

-

Model Number:

-

TTP-LVL

-

Size:

-

Cutting size

-

Thickness:

-

14mm ~ 40mm

-

Moisture content:

-

Below 15%

-

Glue:

-

E2 - E0

-

Core:

-

Pine

-

Moisture:

-

12%

-

MOQ:

-

1x40HQ

-

Density:

-

500-600kg/m3

-

Delivery time:

-

Within 15 Days

-

Packing:

-

Pallet Packing

Banner

Product Description

LVL stands for Laminated Veneer Lumber, it’s a popular engineered wood material with many applications and it can replace sawn timber with many advantages such as

* Higher strength and more durable.

* Fumigation treated and no fungus.

* Can be reused up to 5 times.

* Custom cut size as requirement.

* Higher strength and more durable.

* Fumigation treated and no fungus.

* Can be reused up to 5 times.

* Custom cut size as requirement.

LVL MANUFACTURE PROCESS

1. SELECTING THE CORE VENEER

The core is made from acacia, pine and mixed wood veneer, which increases the Laminated Veneer Lumber strength for more heavy duty packaging purpose. The most beautiful and best veneers are selected and put into production by TTP workers to bring the high quality for each LVL plank.

2. GLUE SPREADING

The veneers are put through glue rolling machine one by one so that the glue is evenly adhered on both sides.

3.VENEER LAY-UP

This is the main different point in manufacturing process between LVL and Plywood. We will arrange the veneers on the conveyer

belt following the same direction. And the veneer is also fixed by plastic staples

This is the main different point in manufacturing process between LVL and Plywood. We will arrange the veneers on the conveyer

belt following the same direction. And the veneer is also fixed by plastic staples

4. COLD PRESS

Cold pressing for a period of 4-8 hours will help to shape the panels temporarily.

Cold pressing for a period of 4-8 hours will help to shape the panels temporarily.

5. HOT PRESS

Our factory is using hot presses with the latest technology, with 6 cylinders for high capacity, stable pressing force, ensuring

flat boards, quite accurate thickness. In turn, put the panels into each tray of the hot press machine, high temperature and

pressure heat the glue to bond the veneer layers together and permanently solidify product structure.

Our factory is using hot presses with the latest technology, with 6 cylinders for high capacity, stable pressing force, ensuring

flat boards, quite accurate thickness. In turn, put the panels into each tray of the hot press machine, high temperature and

pressure heat the glue to bond the veneer layers together and permanently solidify product structure.

6. CUTTING TO SIZE

When it comes to Laminated Veneer Lumber, trimming and cutting is the most important step because each customer often requires

different small dimensions.

When it comes to Laminated Veneer Lumber, trimming and cutting is the most important step because each customer often requires

different small dimensions.

7. INSPECTION

When cutting is completed, our QC team will inspect the quality of the goods. We check very carefully the surface, edge, measure

the MC, and especially check the dimension of LVL. The moisture content we always control is under 18%, it’s will keep the LVL dry

and decrease the moldy rate.

When cutting is completed, our QC team will inspect the quality of the goods. We check very carefully the surface, edge, measure

the MC, and especially check the dimension of LVL. The moisture content we always control is under 18%, it’s will keep the LVL dry

and decrease the moldy rate.

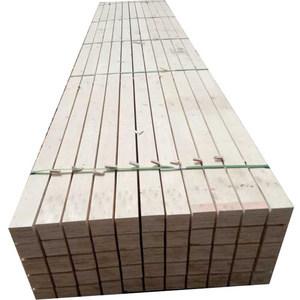

8. PACKAGING

Finally, we count and stack up pcs to create a bundle. Because the size of LVL is often small so that a bundle has thousands pcs.

We use green plastic straps to tie up the bundle, the high strong pallet to make the base, which meet the export standard for

delivery by sea.These bundles are ready to be loaded into containers for delivery to customers.

Finally, we count and stack up pcs to create a bundle. Because the size of LVL is often small so that a bundle has thousands pcs.

We use green plastic straps to tie up the bundle, the high strong pallet to make the base, which meet the export standard for

delivery by sea.These bundles are ready to be loaded into containers for delivery to customers.

Specification

|

Item

|

Value

|

|

Size

|

Cutting size

|

|

Thickness

|

14mm ~ 40mm

|

|

Moisture content

|

Below 15%

|

|

Glue

|

E2 - E0

|

|

Core

|

Pine

|

Product Categories

Hot Searches