- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

5

-

Application:

-

Metal Sheet Stamping

-

Keyword:

-

Pneumatic Metal Punching Machine

-

Material:

-

Carbon Steel

-

After Warranty Service:

-

Service

-

Power Press:

-

Pneumatic Stamping Press

Quick Details

-

Place of Origin:

-

Anhui, China

-

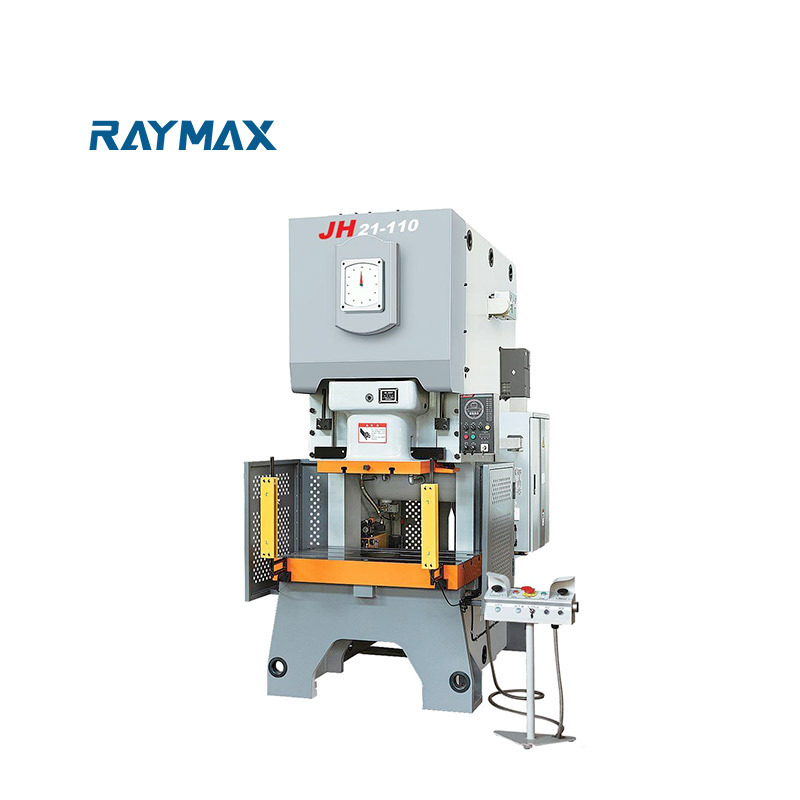

Brand Name:

-

raymax

-

Model Number:

-

JH21

-

Weight (T):

-

5

-

Application:

-

Metal Sheet Stamping

-

Keyword:

-

Pneumatic Metal Punching Machine

-

Material:

-

Carbon Steel

-

After Warranty Service:

-

Service

-

Power Press:

-

Pneumatic Stamping Press

Products Description

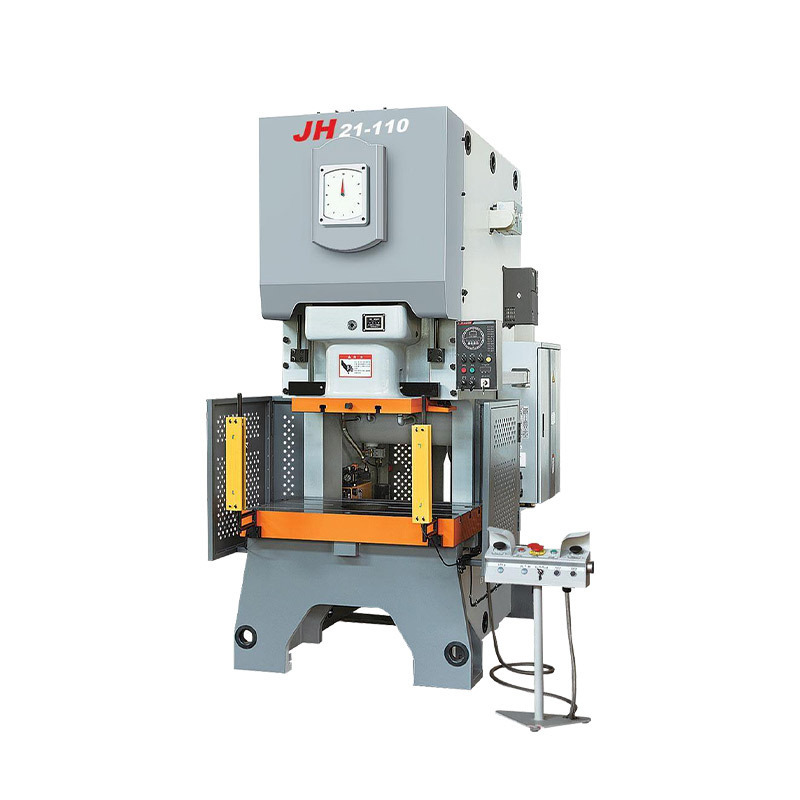

1. Whole structure of the Press:

■ JH21 Series High Precision Presses is one of the new generation of plate process and developed by RAYMAX . The press is for cutting, punching, blanking, bending and light stretching work.

■ C-Type Steel-welded frame, high rigidity and less deformation Compact, wide body frame eliminating vibration for improved idle life and machine.

■ The press adopts hexahedral rectangle lengthen gib, which has high guiding precision and steady precision.

■ Highly advanced, rigidly supported gears, operate in oil bath without any noise saves space, reduces, shaft deflection,

increases gear life.

■ High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

■ The machine by the European Union CE certification and ISO quality system certification.

2. Clutch and brake control system:

■ The Press adopts the low inertia combined dry pneumatic friction clutch and brake from OMPI, Italy, Smoother press performance,

easier maintenance, to ensure reliable safety and flexible action, Iow noise, long service life.

■ Driving gear is installed into the frame and gear is immersed in oil reservoir. Customer could choose Electromagnetic governor, which is stepless speed regulation within a certain range and enlarge the area of craf.

■ Use adopts dual valve from TACO, Japan, which can guarantee the safety and reliability of clutch.

■ Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact;

■ The press adopts cam controller which be combined with proximity switch (Schneider) which will realize the synchronous detection and monitoring reliably.

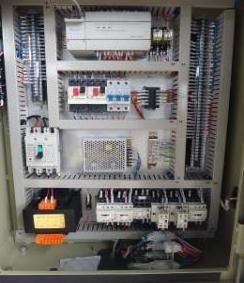

3. Electrical system and the safety interlock:

■ Electrical panel with cooling system designed to meet CE Standards and composed of automation and electrical equipments with SIEMENS brand.

■ Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch, easy to operate.

■ Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

■ Front Side Covers with safety switches, Back light safety guards (Category-4), Foot pedal conforming to CE regulation.

■ Auto grease lubrication system, easy stroke adjustment mechanism increases press versatility tremendously.

■ JH21 Series High Precision Presses is one of the new generation of plate process and developed by RAYMAX . The press is for cutting, punching, blanking, bending and light stretching work.

■ C-Type Steel-welded frame, high rigidity and less deformation Compact, wide body frame eliminating vibration for improved idle life and machine.

■ The press adopts hexahedral rectangle lengthen gib, which has high guiding precision and steady precision.

■ Highly advanced, rigidly supported gears, operate in oil bath without any noise saves space, reduces, shaft deflection,

increases gear life.

■ High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

■ The machine by the European Union CE certification and ISO quality system certification.

2. Clutch and brake control system:

■ The Press adopts the low inertia combined dry pneumatic friction clutch and brake from OMPI, Italy, Smoother press performance,

easier maintenance, to ensure reliable safety and flexible action, Iow noise, long service life.

■ Driving gear is installed into the frame and gear is immersed in oil reservoir. Customer could choose Electromagnetic governor, which is stepless speed regulation within a certain range and enlarge the area of craf.

■ Use adopts dual valve from TACO, Japan, which can guarantee the safety and reliability of clutch.

■ Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact;

■ The press adopts cam controller which be combined with proximity switch (Schneider) which will realize the synchronous detection and monitoring reliably.

3. Electrical system and the safety interlock:

■ Electrical panel with cooling system designed to meet CE Standards and composed of automation and electrical equipments with SIEMENS brand.

■ Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch, easy to operate.

■ Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

■ Front Side Covers with safety switches, Back light safety guards (Category-4), Foot pedal conforming to CE regulation.

■ Auto grease lubrication system, easy stroke adjustment mechanism increases press versatility tremendously.

Details Display

Paramenters

Configuration

|

STANDARD ACCESSORIES"•"

|

OPTIONAL ACCESSORIES"°"

|

|

• Hydraulic Overload Protector

|

° Electrical Automatic Lubrication System

|

|

• Manual Drive Lubrication System

|

° Pneumatic Die Cusion Device

|

|

• Inverter

|

° Preset Counter

|

|

• Electrical Slide Adjust Device

|

° Preset Counter

|

|

• Electrical Die Height Indicator

|

° Foot Switch

|

|

• Balance Device

|

° Quick Die Change Device

(Die lifter, Clamp And Die Arm shift mode)

|

|

• Rotary Cam Switch

|

° Slide Knock-Out Device

|

|

• Crank Angle Indicator

|

° Misfeed Detect Consent

|

|

• Electric Stroke Counter

|

° Power Supply

|

|

• Air Source Receptacle

|

° Anti Vibration Press Mount

|

|

• Against Over-Run Safety Device

|

° Photo-Electronic Safety Device

|

|

• Maintenance Tool Box

|

° Feeder

|

|

• Operation Manual

|

° Uncoiler

|

|

|

° Leveler

|

|

|

° Mechanism Hand

|

|

|

° Die Room Light

|

Punching machine widely used in electronics, communications, computers, household appliances, furniture, transportation, (automobile, motorcycle, bicycle) hardware parts stamping and forming. Basically be aimed at plank. Through the mold, we can make blanking, punching, forming, drawing, dressing, fine punching, shaping, riveting and extrusion parts and so on, widely used in various fields. For example, we use switch sockets, cups, cupboards, dishes, computer cases, there are a lot of accessories can be produced by punching through the mold.

Hot Searches