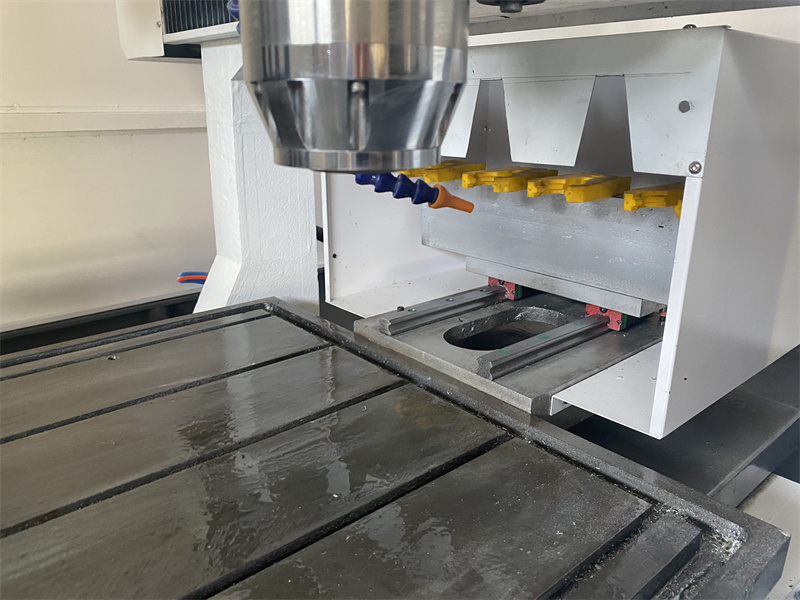

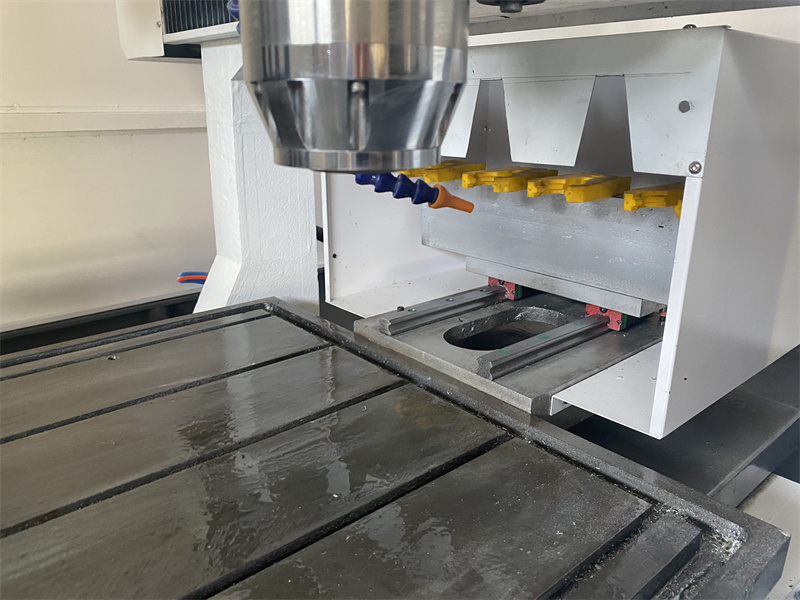

The water circulation is used to cool the heat generated after the high-speed rotation of the main shaft, which has less noise and longer service life. The water cooling system can prolong the service life of the tool.

- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Remax

-

Voltage:

-

AC220/380V,50/60HZ

-

Weight (KG):

-

800

-

Product name:

-

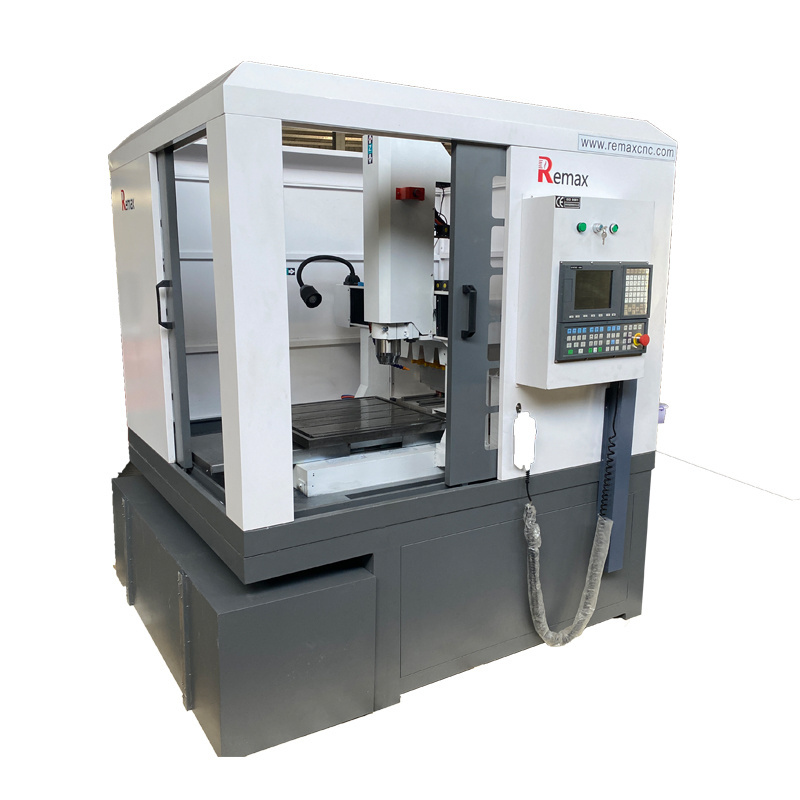

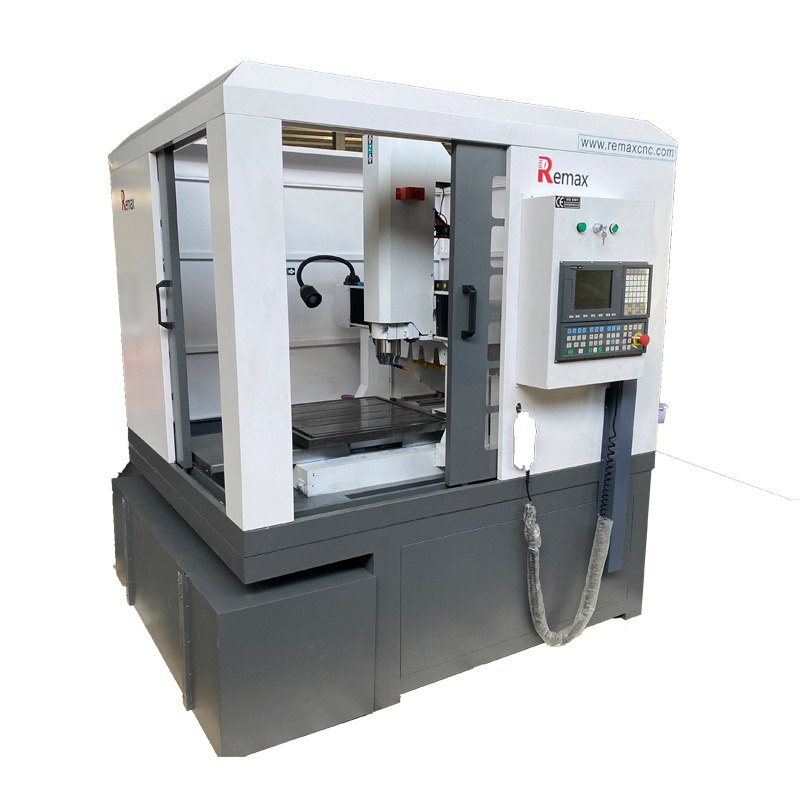

Remax metal cnc router machine 6060

-

Control system:

-

Syntec control system

-

Working area:

-

600x600x200mm

-

Working Voltage:

-

AC220V/380V 50/60Hz

-

Driving system:

-

Leadshine hybrid servo motor and driver

-

Transmission:

-

HIWIN /PMI square rail+Rack

-

Inverter:

-

fulling Inverter

-

Spindle power:

-

2.2kw ATC water cooling spindle

Quick Details

-

Working Table Size(mm):

-

600x600

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Remax

-

Voltage:

-

AC220/380V,50/60HZ

-

Weight (KG):

-

800

-

Product name:

-

Remax metal cnc router machine 6060

-

Control system:

-

Syntec control system

-

Working area:

-

600x600x200mm

-

Working Voltage:

-

AC220V/380V 50/60Hz

-

Driving system:

-

Leadshine hybrid servo motor and driver

-

Transmission:

-

HIWIN /PMI square rail+Rack

-

Inverter:

-

fulling Inverter

-

Spindle power:

-

2.2kw ATC water cooling spindle

Product Information

Remax moulding making machine 6060

JINAN REMAX MACHINERY TECHNOLOGY CO.,LTD

We not only produce machines, we provide best solution for you.

Send Inquiry To Me,Give Best Machine To You

Feature:

☑ Integral cast-iron frame, equipping with double-screw auto eliminating clearance ball screw,floor-type linear guide transmission that can load heavy-duty board but never out of shape and ensure working precision.

☑ High power water-cooling brushless inverter spindle motor, strongly cutting and durable.

☑ High speed driver and stepper motor improve work efficiency.

☑ Special dust-proof and waterproof device prevent dust and rust, and make it easier to maintain.

☑ The machine aggregates advanced technique in CNC industry, with more than 10pcs break-point memory that can reduce waste materials.

☑ High compatibility, applicable to CNC software such as type3,Art cam,Casemate,Pore, Wen tai and various CAD/CAM software..It is easy to process embossment,shadow engraving and three dimensional characters.

☑ Special water-cooling system ensures the cutter a long life.

☑ Our 6060 mould cnc router machine is ATC type cnc router machine with linear type auto tool change function ,and disc auto tool change for option.

☑ Equipped with an ATC tool box of 4 tools that accelerates tool change speed.

Parts

Machine Components

>

ATC Water Cooling Spindle

>

Fulling

Inverter

After adopting frequency conversion speed regulation control, the mechanical system is simplified and the operation and control are more convenient. It can improve the process level and product quality, reduce the impact and noise of the equipment and prolong the service life of the equipment.

>

T

ool Apron of ATC Function

It allows 4 tools to be stored in the tool magazine according to the machine running program, and each tool returns automatically when its task is completed. Automatic tool changing engraving machine can switch between a large number of tools without manual operation, so as to reduce downtime and total production time. It not only improves the efficiency of the machine, but also reduces the labor cost.

> Syntec

Control System

New man-machine interface, clear interface, fast operation, easy to learn and use, and reduce the machine development time. It supports dual program, three program and four program display, machine coordinates, program editing and processing monitoring are presented respectively, the coordinates of each axis group are displayed independently, and each axis group can be simulated at the same time.

>

Auto-Tool Setting Instrument

1. Measure and compensate the tool deviation in the five directions of ± x, ± Z and Y axes

2. Automatic monitoring, alarm and compensation of tool wear or damage during machining

3. Compensation of tool deviation caused by thermal deformation of machine tool.

>

Leadshine Hybrid Servo Driving

It adopts hybrid servo drive control technology, compatible with the dual characteristics of stepping and servo, and has a patent. The hybrid servo overcomes the problem of step loss of open-loop stepping motor, significantly improves the high-speed performance of the motor, reduces the heating and vibration of the motor, improves the machining speed and accuracy, and reduces the energy consumption of the machine.

> Automatic Lubrication

Compared with the traditional lubrication method, the automatic lubrication system can improve the work efficiency by nearly 5 times, save 2 / 3 of lubricating oil, reduce the maintenance cost by about 3 times, and prolong the service life of machine parts; It is simple, easy to install, easy to operate, safe and clean, and has no special requirements for lubricating oil.

|

Description

|

Parameter

|

|

Model

|

Remax cnc mold making machine 6060

|

|

Table surface

|

T slot iron table

|

|

Inveter

|

Fulling inverter

|

|

Lubrication system

|

Automatic lubrication system

|

|

Spindle power

|

2.2KW ATC water cooling spindle

|

|

ATC

|

4 Tools

|

|

Control system

|

Syntec control system

|

|

Motor and Driver

|

Leadshine hybrid servo motor and driver

|

|

Transmission

|

HIWIN/PMI square rail

|

|

Positioning accuracy

|

±0.01/300mm

|

|

Repeat Positioning accuracy

|

0.005/300mm

|

|

Working area(X,Y,Z)

|

600x600x200mm

|

|

Working voltage

|

AC 220 /380 V, 50 /60 HZ

|

|

Limit switch

|

OMRON

|

|

Electrical component

|

Schneider

|

|

Command langurage

|

G-code

|

|

Software

|

Artcam/Type 3

|

|

Computer interface

|

USB

|

Samples

Applicable

industry

Work

This machine increases the power of spindle and servo motor and the bearing capacity of bed, while maintaining the high speed and high precision of spindle, which is suitable for fine machining.

>

Mold industry

<

It is suitable for processing all kinds of 3D molds, and can achieve a variety of processes such as milling, boring, drilling, reaming and tapping.

>

Electronic Hardware Accessories

<

Combined with ATC function, this machine has high precision and strong stability. It can accurately return to the processing origin. It is suitable for processing precision electronic hardware accessories or molds.

>

Badge Carving

<

It can carve all kinds of metal materials such as iron, copper, aluminum, steel, zinc, lead, stainless steel, titanium plate and so on

>

Handicraft Carving

<

By engraving the processing materials fixed on the host worktable with the tools configured according to the processing materials, various plane or three-dimensional relief graphics and characters designed in the computer can be carved to make exquisite handicrafts

Our Service

> Guarantee:

1. 24 months for the whole machine.

2. Within 24 months under normal use and maintenance,

If something is wrong with machine, you will get spare part for free.

3. Out of 24 months, you will get spare part at cost price.

4. You will also get technical support and service all the lifetime.

> Technical support:

1, Technical support by phone, email or MSN/Skype 24 HOURS.

2, Friendly English version manual and operation video CD disk.

3, Engineer available to service machinery overseas.

> After sales services:

1 Normal machine is properly adjusted before dispatch.

2 You will be able to use the machines immediately.

3 You will be able to get free training advice towards our machine in our factory.

4 You will also get free suggestion and consulting, technical support and service by email/fax/tel and lifetime technical support.

1. 24 months for the whole machine.

2. Within 24 months under normal use and maintenance,

If something is wrong with machine, you will get spare part for free.

3. Out of 24 months, you will get spare part at cost price.

4. You will also get technical support and service all the lifetime.

> Technical support:

1, Technical support by phone, email or MSN/Skype 24 HOURS.

2, Friendly English version manual and operation video CD disk.

3, Engineer available to service machinery overseas.

> After sales services:

1 Normal machine is properly adjusted before dispatch.

2 You will be able to use the machines immediately.

3 You will be able to get free training advice towards our machine in our factory.

4 You will also get free suggestion and consulting, technical support and service by email/fax/tel and lifetime technical support.

Our customer

Packing and shipping

Hot Searches