- Product Details

- {{item.text}}

Quick Details

-

Diameter of welded tube:

-

114.3~325.9mm

-

Wall Thickness of welded tube:

-

3-12.7mm

-

Milling speed:

-

10-35M/Min

-

Pipe shape:

-

Round Pipe

-

Cutting system:

-

Cold Cutting Saw/Friction Saw

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanyang

-

Weight (KG):

-

9500

-

Diameter of welded tube:

-

114.3~325.9mm

-

Wall Thickness of welded tube:

-

3-12.7mm

-

Milling speed:

-

10-35M/Min

-

Pipe shape:

-

Round Pipe

-

Cutting system:

-

Cold Cutting Saw/Friction Saw

Products Description

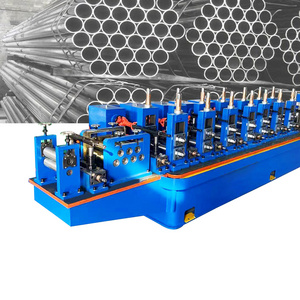

Automatic Weld Tube Mill Round Square Pipe Roll Forming Machine Tube Making Machine

|

Model

|

Welded pipe diameter

|

Welded pipe wall thickness

|

Welding speed

|

Main motor power

|

High frequency power

|

|

ZG90

|

Φ38~Φ127mm

|

δ1.2~4.5mm

|

20~70M/min

|

132KW×2

|

400KW

|

|

ZG115

|

Φ48~Φ127mm

|

δ1.4~5.0mm

|

20~60M/min

|

160KW×2

|

400KW

|

|

ZG165

|

Φ50.8~Φ165mm

|

δ1.8~6.0mm

|

15~50M/min

|

200KW×2

|

500KW

|

|

ZG219

|

Φ89~Φ219mm

|

δ2.0~8.0mm

|

12~40M/min

|

250KW×2

|

600KW

|

|

ZG273

|

Φ114~Φ273mm

|

δ2.5 ~10.0mm

|

10~30M/min

|

132KW×2, 160KW×2

|

800KW

|

|

ZG325

|

Φ168~Φ325mm

|

δ3.0 ~12.0mm

|

10~30M/min

|

160KW×2, 200KW×2

|

1000KW

|

|

ZG530

|

Φ219~Φ530mm

|

δ4.0 ~16.0mm

|

10~30M/min

|

75KW×5, 160KW×8

|

1500KW

|

ABOUT THE PRICE

Firstly, we provide

free customized solution services!

The final price shall be based on the proposed quotation!

Our Feature

s

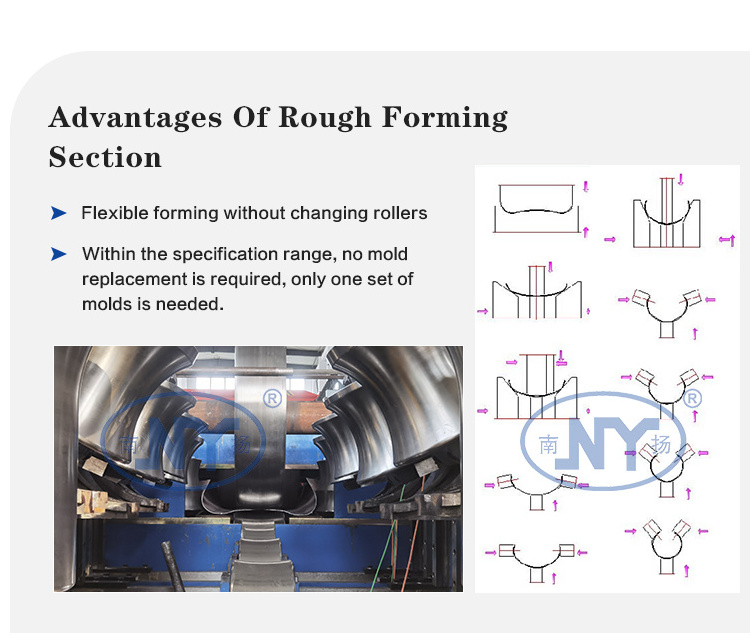

1.Increase production capacity and increase production speed by 50%.

2.Reduce costs, reduce the cost of rough forming molds by over 70%, and reduce energy consumption.

3.Reduce production replacement time, reducing the over all mold replacement timeby over 60%.

4.Improve automation and intelligence, make operations more convenient, reduce labor intensity, and support informatization.

5.lmprove product quality and avoid surface scratches on pipes.

Customer Feedback

Recommend Products

Hot Searches