- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

hongfa

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main materials of Wall slab:

-

Cement/fly ash,sand,foam polystyene particles

-

High capacity:

-

50,000m2 to 1,000,000m2/year

-

Certificate:

-

CE / ISO9001:2015

-

Advantages:

-

Light Weight, fire proof,water proof

-

Product name:

-

EPS wall panel making machine

-

Core material:

-

Foaming eps, cement,

-

Material:

-

EPS+Cement+Sand+additives

-

Thickness:

-

50-250mm

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

hongfa

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main materials of Wall slab:

-

Cement/fly ash,sand,foam polystyene particles

-

High capacity:

-

50,000m2 to 1,000,000m2/year

-

Certificate:

-

CE / ISO9001:2015

-

Advantages:

-

Light Weight, fire proof,water proof

-

Product name:

-

EPS wall panel making machine

-

Core material:

-

Foaming eps, cement,

-

Material:

-

EPS+Cement+Sand+additives

-

Thickness:

-

50-250mm

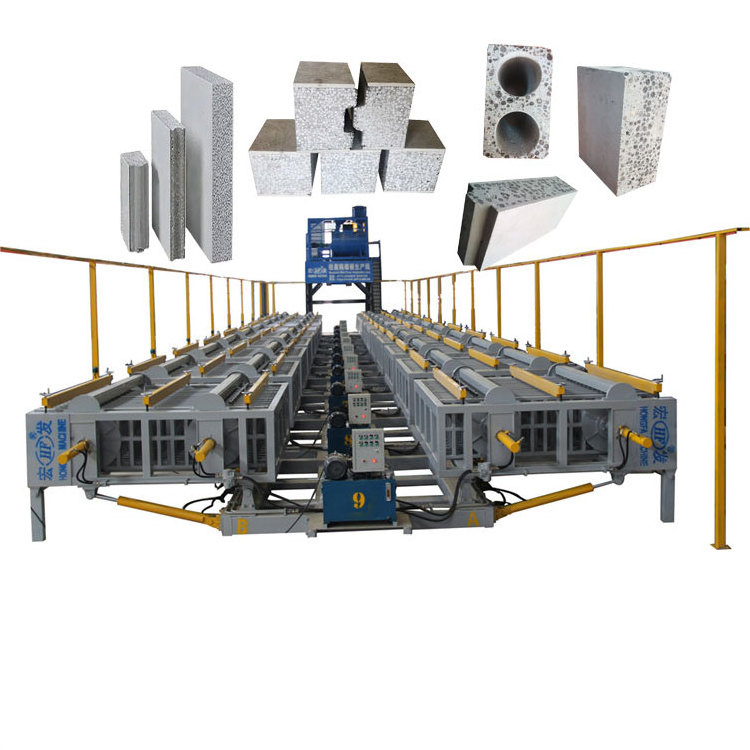

Concrete Wall Panel Lightweight Construction Materials Used 3D Panel Machine 3D Construction Panel System

Wall panel for concrete precast houses:

1. Patent protected product

2. Labor-saving and Advanced Technology

3. Double side opening and higher capacity

4. ISO9001-2015

5.Adopts touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

6. With the same machine, it can adjust the panel size and thickness. The maximum length will

be 6 meters as your requirement. The thickness will be from 60 to 250mm.

The Advantage of Automatic Double-side Opening Wall Panel Making Machine

| New double side opening automatic wall panel making machine | Power/kw | Output/pcs per mould | |||||

| Overall dimension (mm) | 4 | 60mm | 75mm | 90mm | 100mm | 120mm | 150mm |

| 3380*3200*2680mm | 40pcs | 36pcs | 32pcs | 30pcs | 26pcs | 22pcs | |

| Capacity range |

50000sqm to 1 million sqm or more. |

||||||

| Hydraulic system | Hydaulic system for material filling and forming machine. | ||||||

| Worker need | 1 worker can run 3 machines, the fastest now in China. | ||||||

EPS wall panel making machine hollow core board gypsum board production line

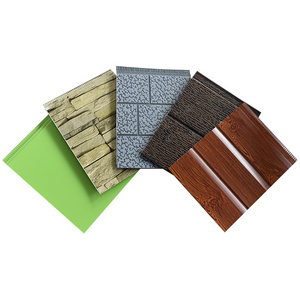

Kinds of wall panels

Introduction of

EPS wall panel making machine hollow core board gypsum board production line

1. Materials of Hongfa Brand EPS Wall Panel

1) Outside (side board)- Calcium silicate board or Cement fiberboard - Also can be without the side board.

2) Inside (core material)- Cement, Foam EPS, Fly Ash, Additives (Hydroxypropyl methyl cellulose) Or without EPS foam The fly ash can be replaceable by sand or other material

2. Common Specifications of

EPS wall panel hollow core board gypsum board

EPS cement wall sandwich panel

L*W*T: 2440mm*610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm.

2270mm* 610mm*50mm/60mm/75mm/90mm/100mm/120mm/150mm/180mm.

Other sizes can be customized.

3. Applied range of EPS wall panel hollow core board gypsum board

For interior and exterior wall partition on steel or concrete structure building, new construction or renovations. It can be widely applied to wall materials of various high and low buildings such as bank, office building, hospital, school, hotel, shopping mall, amusement, old house reconstruction, residence and workshop.

4. Advantages of EPS wall panel hollow core board gypsum board

Light weight----Excellent sound insulation----- Heat Insulation

Waterproof Fire proof--------- Energy Efficient Environmental

Convenient construction-----High Intensity without deformation.

Successful plants of Lightweight Concrete Block EPS wall panel making machine

Three types of

EPS wall panel making machine eps cement sandwich panel production line

1. Horizontal wall panel machine for 50,000-300,000 square meters:

2. Vertical Manual panels de-molding /concrete wall panel making machine/lightweight wall panel making machine

3. Vertical Automatic panels de-molding and stacking/concrete lightweight panel machine:

Workshop of Hongfa panel sandwich machine/ lightweight wall panel making machine/eps sandwich panel production line