- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6050*2530*3460mm

-

Weight:

-

22ton

-

Rated working pressure:

-

0.7 Mpa 1.0Mpa 1.25Mpa 1.6Mpa 2.5Mpa

-

Boiler thermal power 1:

-

300,000kcal 600,000 kcalto 6000,000kcal

-

Boiler thermal power 2:

-

350KW 700KW, 1000KW, 2800KW, 3500KW, 4200KW etc.

-

Output temperature::

-

280 °C 320 °C

-

Working Medium:

-

Heat conduction oil

-

Application:

-

Plywood processing, timber mill, Asphalt solubility

-

Design fuel:

-

Biomass, wood, coal, rice husk hull

-

Company:

-

Boiler factory since 1956

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Core Components:

-

Boiler main body

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanda Boiler

-

Dimension(L*W*H):

-

6050*2530*3460mm

-

Weight:

-

22ton

-

Rated working pressure:

-

0.7 Mpa 1.0Mpa 1.25Mpa 1.6Mpa 2.5Mpa

-

Boiler thermal power 1:

-

300,000kcal 600,000 kcalto 6000,000kcal

-

Boiler thermal power 2:

-

350KW 700KW, 1000KW, 2800KW, 3500KW, 4200KW etc.

-

Output temperature::

-

280 °C 320 °C

-

Working Medium:

-

Heat conduction oil

-

Application:

-

Plywood processing, timber mill, Asphalt solubility

-

Design fuel:

-

Biomass, wood, coal, rice husk hull

-

Company:

-

Boiler factory since 1956

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

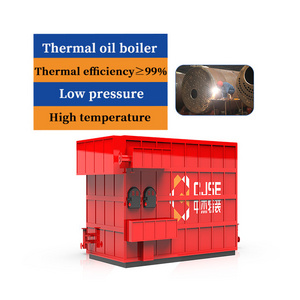

1200000 kcal/hr Biomass Wood Fired Industrial Thermal Oil Boiler for Plywood

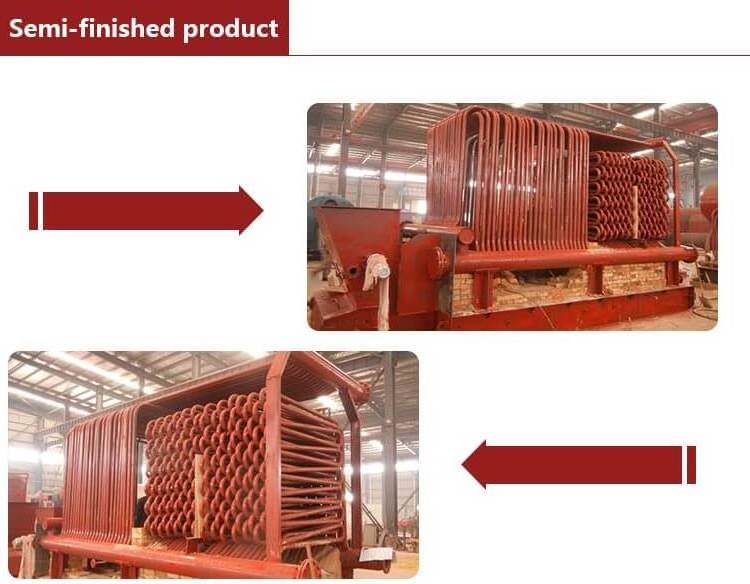

YLW series coal/biomass thermal oil boiler adopts square coil horizontal structure,chain grate automatic fuel feeding,FD/ID fan mechanical ventilation,slag remover for mechanical slag removing while running,the burning fuel enter into the chain grate through the fuel hoppe,then burn.The high-temperature flue gas is reflected to the front of the furnace by the rear arch and enters the furnace chamber.After radiation heat transfer by the radiation heating surface,it enters the convection heating surface for convection heat transfer,then enter into waste heat recovery boiler/air pre-heater,dust catcher,ID fan,finally discharged into air by chimney.

Core Technology

1.Multi-loop coil design

2.Countercurrent heat transfer process

3.Over oil temperature/over smoke temperature/low flow alarm

4.Set up air preheater,waste heat boiler

5.New furnace arch with upside down"α"flue gas flow

6.Advanced and scientific fabric technology

| Boiler Model |

YLW-700 |

YLW-1400 | YLW-2400 | YLW-2900 | YLW-4200 | YLW-5600 | YLW-7000 | YLW-8400 | YLW-10500 | YLW-14000 |

| Rated thermal power(KW) | 700 | 1400 | 3000 | 3500 | 4200 | 5600 | 7000 | 8400 | 10500 | 14000 |

| Rated working pressure(Mpa) | 0.8/1.0 | |||||||||

| Thwemal oil outlet/Inlet feeding temperature(℃) | 280/250;320/290 | |||||||||

| Thermal efficiency(%) | >83 | |||||||||

| Exhaust gas temperature(℃) | <140 | |||||||||

| Fuel type | Soft coal,firewood,rice husk,palm shell and the other biomass fuels | |||||||||

| Fuel consumption (Kg/h) | 187 | 373 | 621.3 | 756 | 989.32 | 1196 | 1657.43 | 1926.2 | 2442.6 | 3230 |

| Max transportation weight(t) | 16.9 | 22 | 28.6 | 24.2 | 30 | 33.6 | 18.2 | 24.3 | 27.5 | 31 |