- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V/440V

-

Current:

-

50A

-

Rated Capacity:

-

50000uA

-

Rated Duty Cycle:

-

50%

-

Dimensions:

-

customized

-

Usage:

-

welding/solding/handing

-

DOF:

-

6

-

Driving Mode:

-

AC servo driving

-

Effective Load (kg):

-

6-165

-

Repeat Positioning Accuracy (mm):

-

±0.05

-

Motion Range (°):

-

±360

-

Max Speed (°/S):

-

270

-

Moving Radius (mm):

-

893

-

Machine Weight:

-

75kg

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Hwashi

-

Weight (KG):

-

500

-

Voltage:

-

380V/220V/440V

-

Current:

-

50A

-

Rated Capacity:

-

50000uA

-

Rated Duty Cycle:

-

50%

-

Dimensions:

-

customized

-

Usage:

-

welding/solding/handing

-

DOF:

-

6

-

Driving Mode:

-

AC servo driving

-

Effective Load (kg):

-

6-165

-

Repeat Positioning Accuracy (mm):

-

±0.05

-

Motion Range (°):

-

±360

-

Max Speed (°/S):

-

270

-

Moving Radius (mm):

-

893

-

Machine Weight:

-

75kg

-

After Warranty Service:

-

Video technical support

Hanging

Welding Robot Arm

Welding Sample—Scaffolding

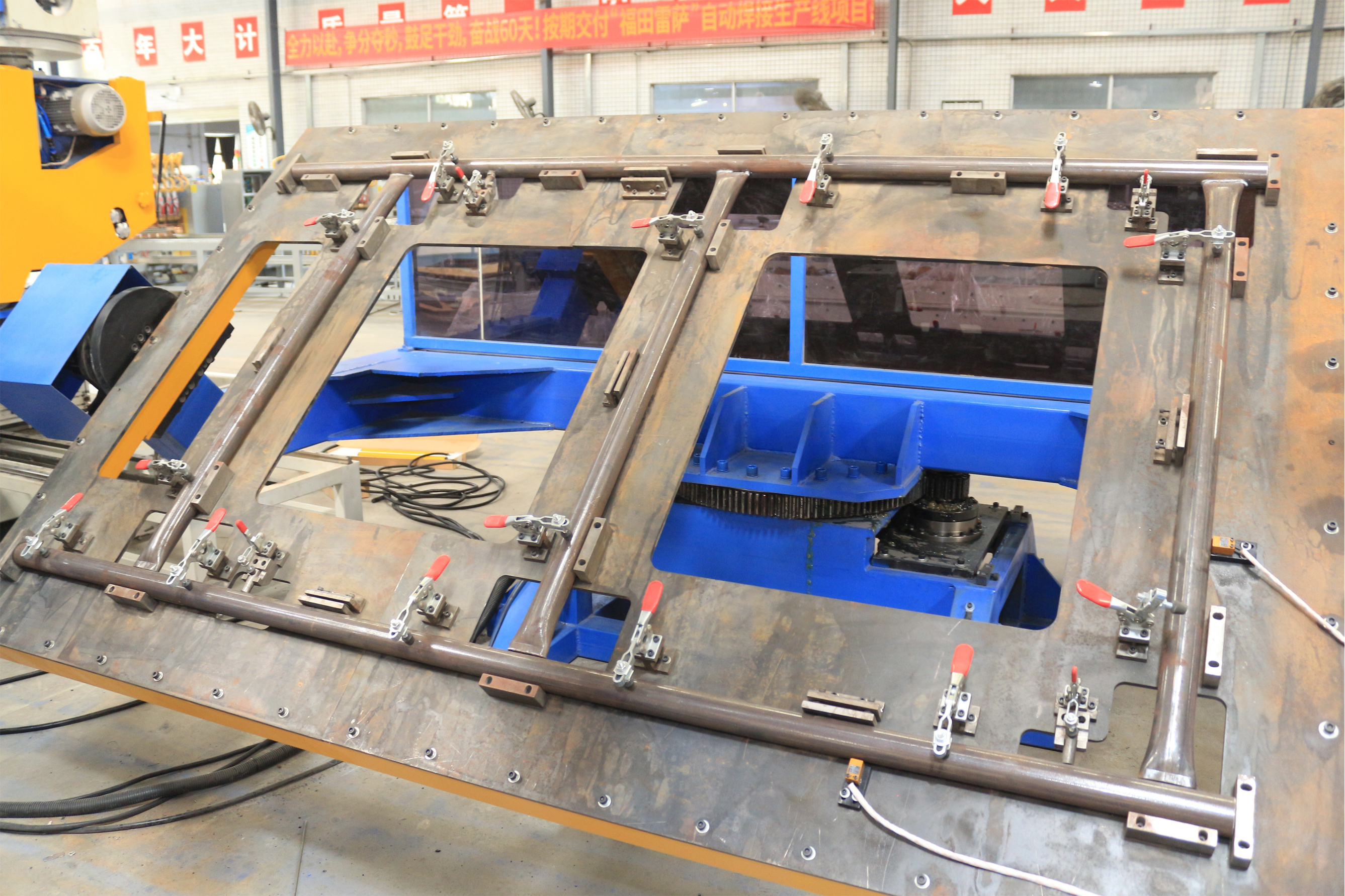

Custom Product Fixture

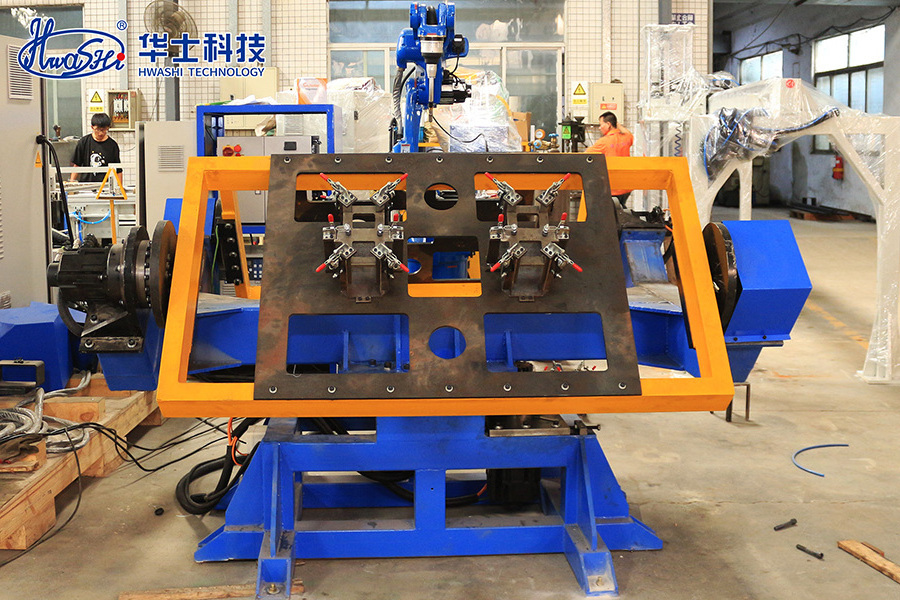

Double-Station Robot Postioner

Scaffolding welding machine, Robots for welding scaffolding

Product Application

HWASHI Scaffolding Robotic Welding machine is designed for welding the chair. Adopt 6 axis robot with MIG welder for automatic welding. Use cylinder to clamp the work piece. Use the lever principle to fix the product and ensure the location requirement for robotic automatic welding. Ensure each position could be welded and the fixture is designed with 2 sets in order to meet the production requirement. One set for loading, one set for welding.

Main Features

The whole robotic system for HWASHI 6 Axis 1.4m Robot Arm Furniture Chair Frame MIG Welding Robot use includes the following components:

8kg payload 1.4m robot arm 2 set;

Panasonic 350A MIG welding machine 2 set;

One axis 360°rotation positioner 2 sets;

Fixtures 2 sets;

Welding gun cleaner 1 set

Workflow

2) Start welding;

3) The robot and welding machine will do welding on the workpiece according to the presetting program;

4) Welding completed;

5) While the station 1 is being welded, station 2 is being loaded and fixed the work piece synchronously. Two stations work

alternately.

6) Cycle working

7) This machine can achieve automatic welding with manually loading material. It can also improve the welding quality and welding

efficiency. What’s more, it can reduce the production cost. The problem of unstable quality and low production efficiency caused

by pure manual operation has been solved.

Machine list

1. Positioner, manual loading;

2. Cylinder for clamping the product;

3. Cylinder to turn over the fixture;

4. Robot automatic welding;

5. Manual unloading the product;

6. Welding gun cleaner device

|

Model

|

|

HS-R6-08

|

HS-R6-10

|

HS-R6-20

|

HS-R6-50

|

HS-R6-165

|

|||||

|

DOF

|

|

6

|

|

|

|

|

|||||

|

Driving Mode

|

|

AC Servo Driving

|

|

|

|

|

|||||

|

Effective Load

|

|

8KG

|

10KG

|

20KG

|

50KG

|

165KG

|

|||||

|

Repeat Accuracy

|

|

±0.05mm

|

|

|

|

|

|||||

|

Working radius

|

|

1400mm

|

1589mm

|

1595mm

|

1950mm

|

2483mm

|

|||||

|

Weight

|

|

180KG

|

180KG

|

290KG

|

600KG

|

1300KG

|

|||||

|

Motion Range(°)

|

J1

|

±170

|

±170

|

±170

|

±180

|

±180

|

|||||

|

|

J2

|

±120~-85

|

±120~-80

|

±132~-95

|

±130~-90

|

±80~-60

|

|||||

|

|

J3

|

±85~-165

|

±85~-165

|

±73~-163

|

±75~-210

|

±80~-190

|

|||||

|

|

J4

|

±180

|

±180

|

±180

|

±360

|

±360

|

|||||

|

|

J5

|

±135

|

±135

|

±133

|

±115

|

±115

|

|||||

|

|

J6

|

±360

|

±360

|

±360

|

±360

|

±360

|

|||||

|

Max Speed(°/s)

|

J1

|

130

|

130

|

147

|

158

|

100

|

|||||

|

|

J2

|

130

|

130

|

100

|

149

|

90

|

|||||

|

|

J3

|

130

|

130

|

135

|

130

|

104

|

|||||

|

|

J4

|

270

|

270

|

300

|

215

|

144

|

|||||

|

|

J5

|

170

|

170

|

198

|

251

|

160

|

|||||

|

|

J6

|

455

|

455

|

194

|

365

|

215

|

|||||

|

Power

|

|

4KVA

|

4KVA

|

6KVA

|

14KVA

|

31KVA

|

|||||

|

Voltage

|

|

380V or 220V

|

|

|

|

|

|||||

|

Frequency

|

|

50Hz or 60Hz

|

|

|

|

|

|||||

Robot Welding Processes

HWASHI

22

years+ experience welding solutions expert

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable

technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.