- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

4000 mm

-

Backgauge Travel (mm):

-

5 - 500 mm

-

Throat Depth (mm):

-

250 mm

-

Brand Name:

-

MYT

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

2750x1300x1800mm

-

Year:

-

2022

-

Applicable Industries:

-

Other

-

Marketing Type:

-

Hot Product 2021

-

Model:

-

Hydraulic cutting machine

-

System:

-

E21s cnc system

-

Cutting Angle:

-

1.30"

-

Material Strength:

-

450

-

Backgauge range:

-

20-500mm

-

Travel times:

-

14Times/min

-

Power:

-

7.5kw

-

Dimension:

-

4600x1500x1550mm

-

Electrics:

-

Schneider

-

Weight:

-

4tons

Quick Details

-

Max. Cutting Width (mm):

-

6

-

Max. Cutting Thickness (mm):

-

3200 mm

-

Shearing Angle:

-

1

-

Blade Length (mm):

-

4000 mm

-

Backgauge Travel (mm):

-

5 - 500 mm

-

Throat Depth (mm):

-

250 mm

-

Brand Name:

-

MYT

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

2750x1300x1800mm

-

Year:

-

2022

-

Applicable Industries:

-

Other

-

Marketing Type:

-

Hot Product 2021

-

Model:

-

Hydraulic cutting machine

-

System:

-

E21s cnc system

-

Cutting Angle:

-

1.30"

-

Material Strength:

-

450

-

Backgauge range:

-

20-500mm

-

Travel times:

-

14Times/min

-

Power:

-

7.5kw

-

Dimension:

-

4600x1500x1550mm

-

Electrics:

-

Schneider

-

Weight:

-

4tons

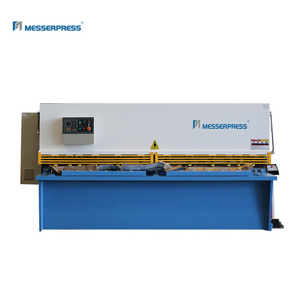

MYT Good price CNC hydraulic shearing machine for metal shearing

Product Description

1.Streamlined design originated from EU, the machine frame is a whole through overall welding and annealing treatment.

2.Reliable Germany Rexroth integrated hydraulic system and hydraulic transmission; the design can effectively reduce problems caused by leakage of hydraulic fluid.

3.Hydraulic swing beam shearing machine is one kind of equipment by swinging the upper blade to shear plate with smaller shearing angle and distortion, improving shearingquality.

4.Backgauge is adjusted by high-precision ball screw driven by E21S controller, during the process frequency convertor prevent positioning device horizontal swinging, significantly improving positioning accuracy.

5.Light aligning device, convenient for manual operation; pressure cylinder with built-in spring mechanism and bottom end

furnished with special material gasket to prevent aluminum or other soft materials from being imprinted.

6.Made by high-quality alloy tool steel, the machine can meet the requirements of impacting load and high wear resistance when working.

furnished with special material gasket to prevent aluminum or other soft materials from being imprinted.

6.Made by high-quality alloy tool steel, the machine can meet the requirements of impacting load and high wear resistance when working.

7.Light and practical cantilever referring to man-machine engineering design, easy NC operation interface with features of

high precision and more comfortable.8.The worktable adopts the rolling steel ball to reduce the frictional resistance, protect the work piece surface; novel protective devices complying with safety specifications: protecting the operator’s personal safety; ingenious design: petty material can be cutter easily.

high precision and more comfortable.8.The worktable adopts the rolling steel ball to reduce the frictional resistance, protect the work piece surface; novel protective devices complying with safety specifications: protecting the operator’s personal safety; ingenious design: petty material can be cutter easily.

9.Front material supporter is equipped with Perpendicularity and positioning regulator to ensure the cutting accuracy, easy

operation, practical and efficient.

10.Rapid adjustment mechanism for rearranging blade clearance, simple operation by hand and adjusting steplessly.

operation, practical and efficient.

10.Rapid adjustment mechanism for rearranging blade clearance, simple operation by hand and adjusting steplessly.

Detail images

Front side of shearing machine

NC shearing machine

Estun system E21S

Schneider electrics

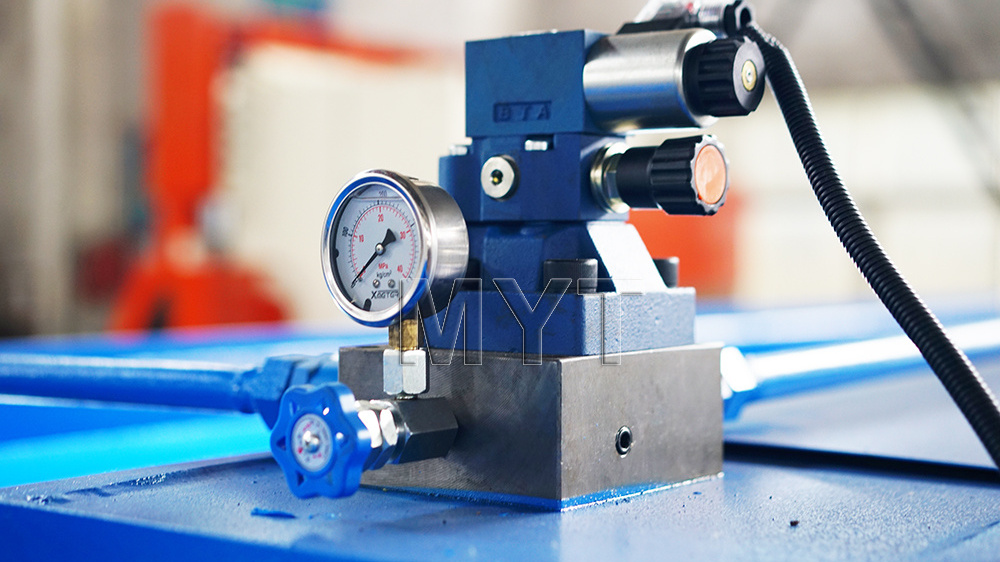

Bosch hydraulic valve

Siemens motor and sunny pump

Manually adjust blade gap

Backage motor

Specification

|

No.

|

Item

|

8*2500

|

8*3200

|

8*4000

|

E21S

|

|

1

|

Max.shearing thickness

|

8

|

8

|

8

|

mm

|

|

2

|

Max.shearing width

|

2500

|

3200

|

4000

|

mm

|

|

3

|

Shearing angle

|

1°30'

|

1°30'

|

1°30'

|

°

|

|

4

|

Material intension

|

≤450

|

≤450

|

≤450

|

kn/cm

|

|

5

|

Back gauge adjust range

|

20-500

|

20-500

|

20-600

|

mm

|

|

6

|

Stroke

|

11

|

8

|

8

|

times/min

|

|

7

|

Main motor

|

7.5

|

7.5

|

7.5

|

kw

|

|

8

|

Dimension(L*W*H)

|

3100*1650*1780

|

3800*1650*1800

|

4800*1650*1800

|

mm

|

Hot Searches