- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

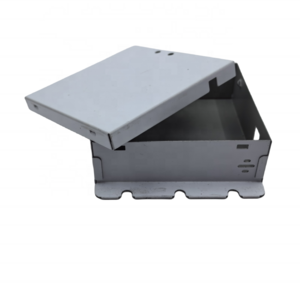

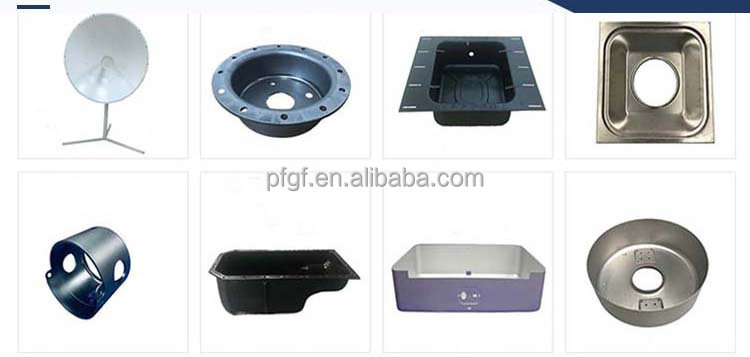

Custom sheet metal stamping deep drawn process

-

Material:

-

Steel/Aluminum/Stainless Steel/SECC/Copper

-

Process:

-

Stamping/Deep drawn

-

Tolerance:

-

0.01-0.05mm

-

Certificate:

-

ISO

-

Type:

-

Fabricated Sheet Metal Parts

-

Finish:

-

Powder coating/Anodize/Electroplating/Polishing

-

Keyword:

-

OEM Precision Sheet Metal Fabrication

-

Delivery Time:

-

20-25 days

-

Technology:

-

15 Years Experience

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Pengfeng

-

Model Number:

-

OEM

-

Product name:

-

Custom sheet metal stamping deep drawn process

-

Material:

-

Steel/Aluminum/Stainless Steel/SECC/Copper

-

Process:

-

Stamping/Deep drawn

-

Tolerance:

-

0.01-0.05mm

-

Certificate:

-

ISO

-

Type:

-

Fabricated Sheet Metal Parts

-

Finish:

-

Powder coating/Anodize/Electroplating/Polishing

-

Keyword:

-

OEM Precision Sheet Metal Fabrication

-

Delivery Time:

-

20-25 days

-

Technology:

-

15 Years Experience

Product Description

The Deep Drawn Stamping Process Although it can be modified to manufacture particular parts, our deep drawn stamping process typically follows the same five steps:

1.Design Review: Our engineers review the part design in detail to ensure it is appropriate for deep drawn stamping. This includes in-depth analysis of component dimensions, materials, draw ratio, and required tolerances.

2.Press Selection: Our engineers determine which machine size and caliber will be best suited for the part dimensions and material.

2.Press Selection: Our engineers determine which machine size and caliber will be best suited for the part dimensions and material.

3. 3D Virtual Prototyping: A prototype of the part is created using virtual software. The prototype is run through numerous operational simulations to catch any design problems before the production process begins.

4. Equipment Setup: Our skilled engineers review the component dimensions and requirements and set up the die and punch.

5. Deep Draw Process: The sheet metal, or metal blank, is placed on the die and secured. The press is then activated to force the punch against the die with up to 400 tons of force. The process is repeated until the component achieves the desired size and

shape.

5. Deep Draw Process: The sheet metal, or metal blank, is placed on the die and secured. The press is then activated to force the punch against the die with up to 400 tons of force. The process is repeated until the component achieves the desired size and

shape.

Hot Searches