- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TOPFRP

-

Model Number:

-

Diameter 3-40 mm

-

Surface Treatment:

-

thread

-

Material:

-

Fiberglass Basalt Carbon fiber and epoxy resin

-

Diameter:

-

3-40mm

-

Tensile Strength:

-

509MPa-1900MPa

-

E-modulus:

-

more than 40Gpa

-

Density:

-

2.0-2.2g/cm3

-

Resistance to alkali:

-

>75%

-

Feature:

-

High Strength,Corrosion Resistant

-

OEM:

-

Accepted

Quick Details

-

Application:

-

Construction

-

Technique:

-

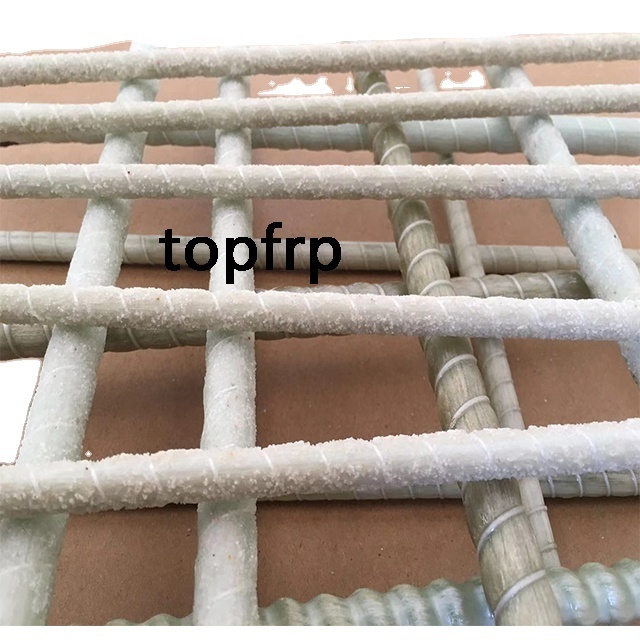

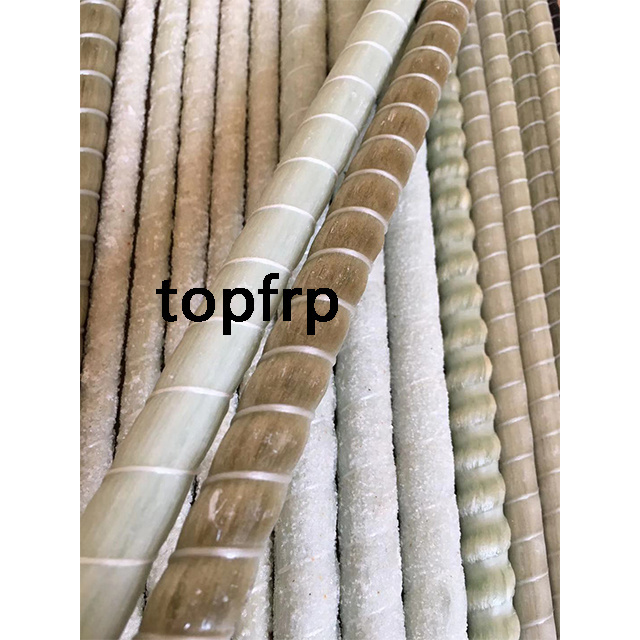

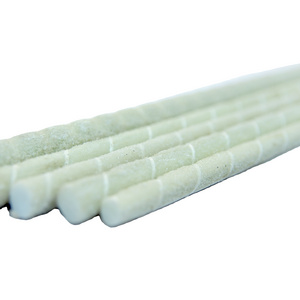

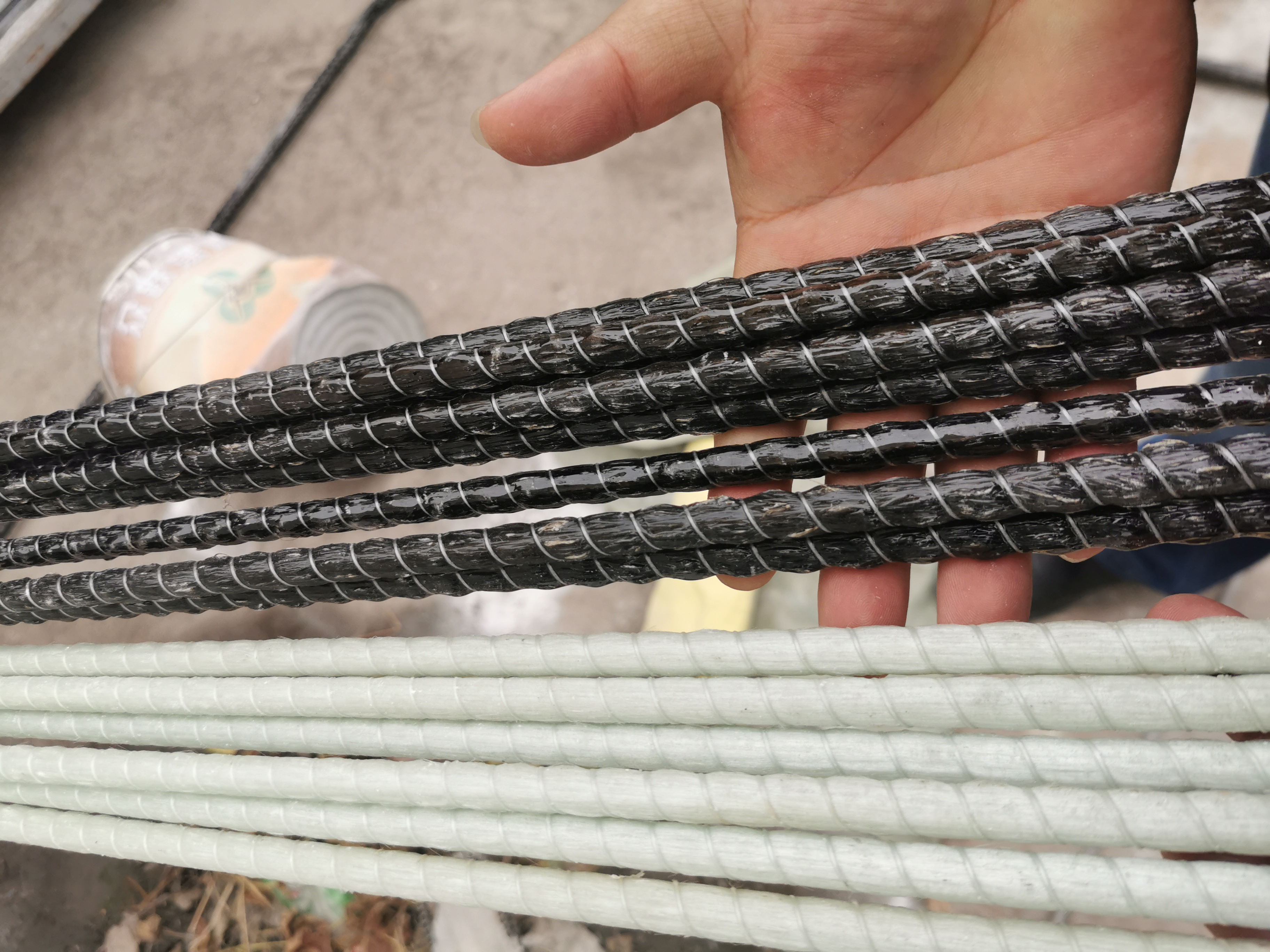

Pultrusion and Winding

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TOPFRP

-

Model Number:

-

Diameter 3-40 mm

-

Surface Treatment:

-

thread

-

Material:

-

Fiberglass Basalt Carbon fiber and epoxy resin

-

Diameter:

-

3-40mm

-

Tensile Strength:

-

509MPa-1900MPa

-

E-modulus:

-

more than 40Gpa

-

Density:

-

2.0-2.2g/cm3

-

Resistance to alkali:

-

>75%

-

Feature:

-

High Strength,Corrosion Resistant

-

OEM:

-

Accepted

1. High corrosion resistance

-The fiberglass used by the rebar are durable materials, and they are molded through the composite process. The life span is up to 100 years. They can be used as permanent support materials.

2. A high tensile strength

-The load is approximately double that of a steel bar with the same diameter

3. Low weight

-The weight is only 1/4 that of a steel bar with the same diameter, therefore, the labor intensity is greatly reduced, and the transportation cost is reduced at the same time

4. Anti-static

-It has no electrical conductivity, and no sparks will be produced when being cut, it's particularly suitable for high gas zones;

5. Non-flammable

-It's non-flammable and has high thermal isolation;

6. Cuttability

-It avoids damages to cutter heads and does not delay excavation

7. Save cost

-Use this material as reinforcing bars for road and bridge, could reduce secondary repair cost.

Applications:

Сonstruction, transportation industry, coal mine tunnel, parking structures, half coal roadway, slope support, subway tunnel, rock surface anchoring, sea wall, and dam etc.

------------------------------ Technical Index o f GFRP Rebar-----------------------------

|

Diameter

(mm)

|

Cross Section

(mm2)

|

Density

(g/cm3)

|

Weight

(g/m)

|

Ultimate Tensile Strength

(MPa)

|

Elastic

Modulus

(GPa)

|

|

3

|

7

|

2.2

|

18

|

1900

|

>40

|

|

4

|

12

|

2.2

|

32

|

1500

|

>40

|

|

6

|

28

|

2.2

|

51

|

1280

|

>40

|

|

8

|

50

|

2.2

|

98

|

1080

|

>40

|

|

10

|

73

|

2.2

|

150

|

980

|

>40

|

|

12

|

103

|

2.1

|

210

|

870

|

>40

|

|

14

|

134

|

2.1

|

275

|

764

|

>40

|

|

16

|

180

|

2.1

|

388

|

752

|

>40

|

|

18

|

248

|

2.1

|

485

|

744

|

>40

|

|

20

|

278

|

2.1

|

570

|

716

|

>40

|

|

22

|

355

|

2.1

|

700

|

695

|

>40

|

|

25

|

478

|

2.1

|

970

|

675

|

>40

|

|

28

|

590

|

2.1

|

1195

|

702

|

>40

|

|

30

|

671

|

2.1

|

1350

|

637

|

>40

|

|

32

|

740

|

2.1

|

1520

|

626

|

>40

|

|

34

|

857

|

2.1

|

1800

|

595

|

>40

|

|

36

|

961

|

2.1

|

2044

|

575

|

>40

|

|

40

|

1190

|

2.1

|

2380

|

509

|

>40

|

-----------------------------Pultrusion Process of FRP Rebar---------------------------

---------------------------------Application of FRP Rebar--------------------------------

GFRP rebar have become a material for replacing steel bars in reinforced concrete structures, and have good corrosion resistance and electromagnetic neutrality.

1. widely used in highways, bridges, airports, terminals, stations, water conservancy projects, underground engineering and other fields

2. Suitable for corrosive environments such as sewage treatment plants, chemical plants, electrolysis tanks, manhole covers, and coastal defense projects.

3. Suitable for military engineering, confidential engineering, special engineering, etc.