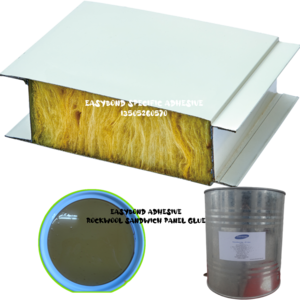

985 is a polyurethane Structural adhesive that reacts with a curing agent at room temperature to form a rubber elastic body after curing.

It is used for bonding wood, leather, fabric, paper, cement, concrete, aluminum, galvanized steel, etc.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JIAGU

-

Model Number:

-

HY985

-

Type:

-

Auto adhesive

-

Product name:

-

PU Polyurethane Adhesive

-

Main Material:

-

PU

-

Application:

-

Carriage floor

-

Appearance:

-

white

-

Density:

-

1.5

-

Viscosity:

-

10~30

-

Operational time (h):

-

1.0

-

Flame-retardant:

-

v0

-

Curing time (h):

-

24~48

-

Certificate:

-

RoHS REACH

Quick Details

-

CAS No.:

-

51852-81-4

-

Other Names:

-

polyurethane glue

-

Place of Origin:

-

China

-

Brand Name:

-

JIAGU

-

Model Number:

-

HY985

-

Type:

-

Auto adhesive

-

Product name:

-

PU Polyurethane Adhesive

-

Main Material:

-

PU

-

Application:

-

Carriage floor

-

Appearance:

-

white

-

Density:

-

1.5

-

Viscosity:

-

10~30

-

Operational time (h):

-

1.0

-

Flame-retardant:

-

v0

-

Curing time (h):

-

24~48

-

Certificate:

-

RoHS REACH

Two-polyurethane Structural Adhesive

Product Features

1. Solvent-free, environmentally friendly and low-carbon.

2. It has permanent flexibility.

3. Excellent weather resistance, aging resistance, UV resistance.

4. Good acid and alkali resistance.

5. Suitable for bonding a variety of materials.

6. Uniform adhesive layer and good adhesion. No bubbling.

7. Non-corrosive.

2. It has permanent flexibility.

3. Excellent weather resistance, aging resistance, UV resistance.

4. Good acid and alkali resistance.

5. Suitable for bonding a variety of materials.

6. Uniform adhesive layer and good adhesion. No bubbling.

7. Non-corrosive.

Main Applications

1. It is suitable for bonding the floor leather of trains, buses, automobiles, vehicles, machinery and equipment to the floor of the carriages.

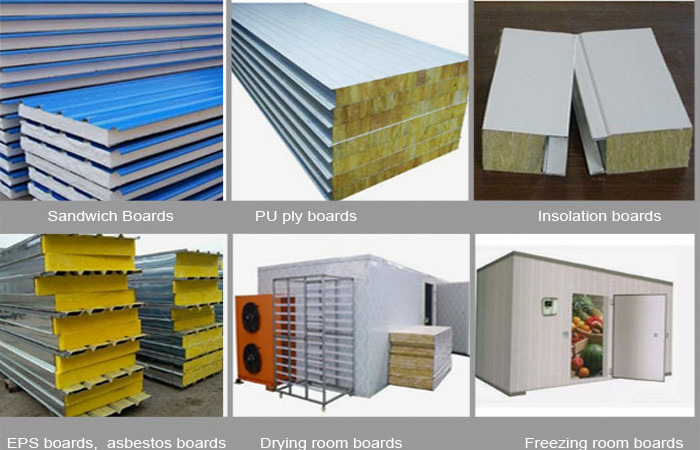

2. It is suitable for the insulation and decoration integrated board industry: such as the bonding of inorganic boards, aluminum honeycomb panels, glass steel and various insulation materials. It has good adhesion to the surface of metal, wood, plastic and hard foam materials.

3.It is used for producing filter, bonding polyester to steel plate.

4.It is used for producing sandwich board , particleboard,honeycomb,cellular board.

2. It is suitable for the insulation and decoration integrated board industry: such as the bonding of inorganic boards, aluminum honeycomb panels, glass steel and various insulation materials. It has good adhesion to the surface of metal, wood, plastic and hard foam materials.

3.It is used for producing filter, bonding polyester to steel plate.

4.It is used for producing sandwich board , particleboard,honeycomb,cellular board.

Polyurethane structural adhesive for manufacturing sandwich panel ,honeycomb board ,making particleboard and bonding panel board to steel plate

Operation Process

|

HY985

|

Common type

|

fast curing

|

|

|

Main Chemical Composition

|

PU

|

|

|

|

Color

|

white/yellow

|

|

|

|

Density (g/cm3)

|

1.5

|

|

|

|

Viscosity (Pa.S)

|

10~50(adjustable)

|

|

|

|

Curing accelerator

|

yellow

|

|

|

|

Curing mechanism

|

Activation curing

|

|

|

|

Operational time (min)

|

30

|

5

|

|

|

Initial curing time (min)

|

50~120

|

2~4

|

|

|

Full curing time (h)

|

24~48

|

|

|

|

Peel strength (N/mm)

|

6

|

|

|

|

Applicable temperature (℃)

|

-60~120

|

|

|

|

Flame retardancy (UL)

|

V0

|

|

|

Preliminary preparation

The surface of the board should be clean and dry (the moisture content of the wood is ≤16%), and the surface of the aluminum board should be polished without oil and dust.

Mixed glue

Add the curing accelerator to the sealant material compound in proportion (5:1), stir evenly, and the color is consistent.

The mixed glue should be used up within 30 minutes.

Gluing and construction

Pour the mixed glue on the board, and use a scraper to evenly scrape the glue, so that the glue is evenly coated and does not leak; or the glue machine is evenly coated. The best coating amount is 200~300g/m 2 .

After the glue is applied, cover the other side with the sticky material, and pay attention to venting the air between the two bonding surfaces, so as to be smooth and without waves.

Rolling curing

Use iron rollers to roll from the middle to the edges one to two times to ensure that there is no air in the bonding surface and

100% compaction and adhesion. And compact with heavy objects.

Do not engage in the next process within 12 hours, and do not soak or tear within 24 hours. If you are engaged in the next process, you must protect it.

The surface of the board should be clean and dry (the moisture content of the wood is ≤16%), and the surface of the aluminum board should be polished without oil and dust.

Mixed glue

Add the curing accelerator to the sealant material compound in proportion (5:1), stir evenly, and the color is consistent.

The mixed glue should be used up within 30 minutes.

Gluing and construction

Pour the mixed glue on the board, and use a scraper to evenly scrape the glue, so that the glue is evenly coated and does not leak; or the glue machine is evenly coated. The best coating amount is 200~300g/m 2 .

After the glue is applied, cover the other side with the sticky material, and pay attention to venting the air between the two bonding surfaces, so as to be smooth and without waves.

Rolling curing

Use iron rollers to roll from the middle to the edges one to two times to ensure that there is no air in the bonding surface and

100% compaction and adhesion. And compact with heavy objects.

Do not engage in the next process within 12 hours, and do not soak or tear within 24 hours. If you are engaged in the next process, you must protect it.

Packing & shipping

30KG/set

Certifications

R & D

In the field of adhesives, we are not only a manufacturer, but also a total solution provider covering bonding, sealing and potting processes.

Since its establishment, our company has always adhered to the scientific development concept, and regards technology research and development and personnel training as the company's development goals. Our company has set up a special technical research and development department, and has a technical research and development team with high education, rich experience and strong innovation ability. The company has 6 senior engineers, 4 intermediate engineers and 10 professional technicians, with an average age of about 40 years old. The company pays attention to the recruitment and training of talents. The company recruits technical R&D personnel for a long time and continuously enriches the R&D team. At the same time, the company regularly conducts professional training for existing talents, and also arranges organizations to observe and study in other enterprises, so as to continuously improve the professionalism of R&D personnel. knowledge and innovation. The company also attaches great importance to the research and development of new products. Every year, it invests a lot in the research and development of new products and has achieved great results.

Exhibition

Hot Searches