- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vansen

-

Application:

-

PP PE film,bags,woven, Plastic Bottle Recycling Machine

-

Production Capacity (kg/h):

-

500 - 2000

-

Voltage:

-

380V 50HZ or customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

11kw

-

Weight (T):

-

1

-

Raw material:

-

PET PP PE PVC

-

Usage:

-

Plastic Reuse

-

Type:

-

High Efficiency

-

Capacity:

-

500-3000 Kg/h

-

Color:

-

Customized Color

-

Advantage:

-

High Efficiency Low Energy

-

Material Processed:

-

Plastic Crushing Washing Drying

-

Function:

-

Make Recycling Cleaning

-

Final use of PET Flake:

-

Bottle Pellets

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

5000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Vansen

-

Application:

-

PP PE film,bags,woven, Plastic Bottle Recycling Machine

-

Production Capacity (kg/h):

-

500 - 2000

-

Voltage:

-

380V 50HZ or customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

11kw

-

Weight (T):

-

1

-

Raw material:

-

PET PP PE PVC

-

Usage:

-

Plastic Reuse

-

Type:

-

High Efficiency

-

Capacity:

-

500-3000 Kg/h

-

Color:

-

Customized Color

-

Advantage:

-

High Efficiency Low Energy

-

Material Processed:

-

Plastic Crushing Washing Drying

-

Function:

-

Make Recycling Cleaning

-

Final use of PET Flake:

-

Bottle Pellets

Product Description

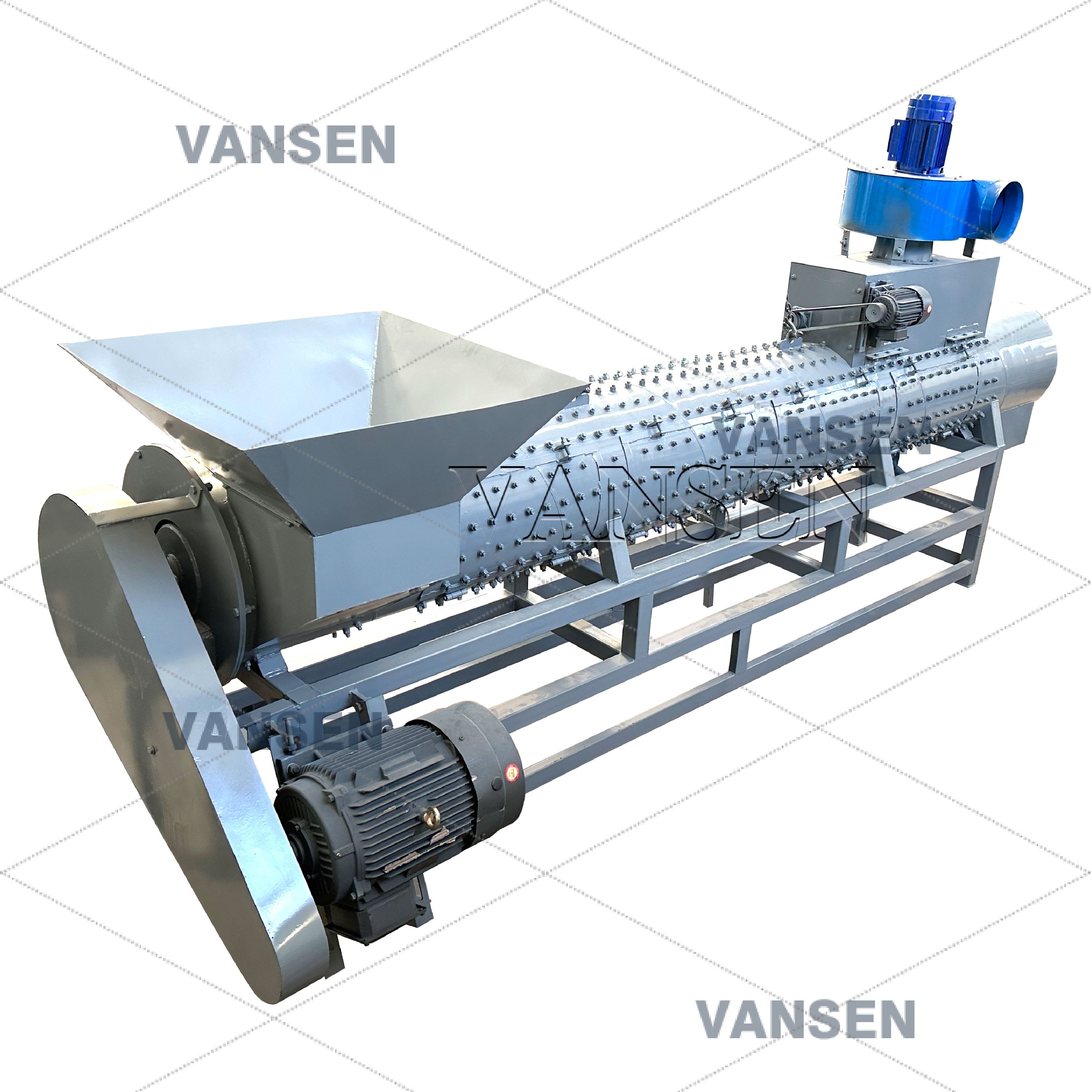

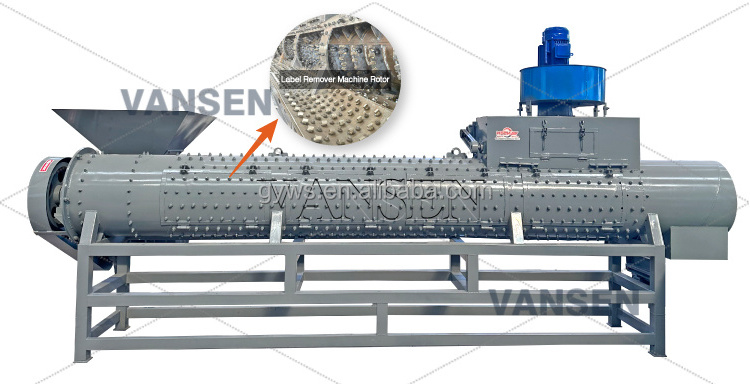

Label Remover Machine is a kind of equipment specially for stripping all kinds of PET bottles andflask packaging label paper. t is a necessary equipment for PET bottle material breaking andrurther cleaning and processing. lt is mainly to meet the production demand of PET bottle off the abel paper section on the PET bottle cleaning line. The successful

development of this productnas completely changed the current situation of manual labelling and greatly improved the efficiency of production and reduced the labor intensity.

Working Principle :

Transport PET plastic bottle materials to the inlet of the stripper. There is a screw pusher on the front of the stripper body, which pushes the bottles to the stripper part. The spiral friction between the rotating cutter of the spindle and the cutter on the drum water causes the label paper to fall. There is a separation chamber with centrifugal cyclone design at the exit. The peeled label is separated from the PET bottle body.

|

Model

|

Capacity

|

Separation ratio

|

Length

|

Diamention

|

Rotating diameter

|

|

500

|

500Kg/h

|

98%

|

4500mm

|

6350mm*1250mm*2000m500mm

|

500mm

|

|

1000

|

1000Kg/h

|

98%

|

4500mm

|

6350mm*1250mm*2000m500mm

|

500mm

|

|

1500

|

1500Kg/h

|

98%

|

4500mm

|

6350mm*1250mm*2000m500mm

|

500mm

|

|

2000

|

2000Kg/h

|

98%

|

4500mm

|

6350mm*1250mm*2000m500mm

|

500mm

|

For over a decade, our company has always adhered to the business principle of "creatingvalue for customers" as the ulimate goal, market-oriented, and customer-oriented, gathering industry elites to provide customers with comprehensive solutions. At the same time. our products are exported to Japan, South Korea, China, Malaysia, Ecuador, Russia, the Philippines, Indonesia, Ghana, Vietnam and other countries and recions. Received unanimous praise in the industry with eading technology and excellent performance.

Hot Searches