- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Lacing machine

-

Applicable stator stack thickness:

-

8-150MM

-

Maximum stator outer diameter:

-

160mm

-

stator inner diameter:

-

>=30MM

-

Wire package height:

-

10MM-40MM

-

Lashing method:

-

slot by slot, slot by slot, fancy lashing

-

Lashing speed:

-

24 slots ≤ 14S (without knotting 10S)

-

Air pressure:

-

0.5-0.8MPA

-

Power:

-

3KW

-

Transposition time:

-

0.5s

Quick Details

-

Place of Origin:

-

GUA

-

Brand Name:

-

Zongqi

-

Weight (KG):

-

3000

-

Product name:

-

Lacing machine

-

Applicable stator stack thickness:

-

8-150MM

-

Maximum stator outer diameter:

-

160mm

-

stator inner diameter:

-

>=30MM

-

Wire package height:

-

10MM-40MM

-

Lashing method:

-

slot by slot, slot by slot, fancy lashing

-

Lashing speed:

-

24 slots ≤ 14S (without knotting 10S)

-

Air pressure:

-

0.5-0.8MPA

-

Power:

-

3KW

-

Transposition time:

-

0.5s

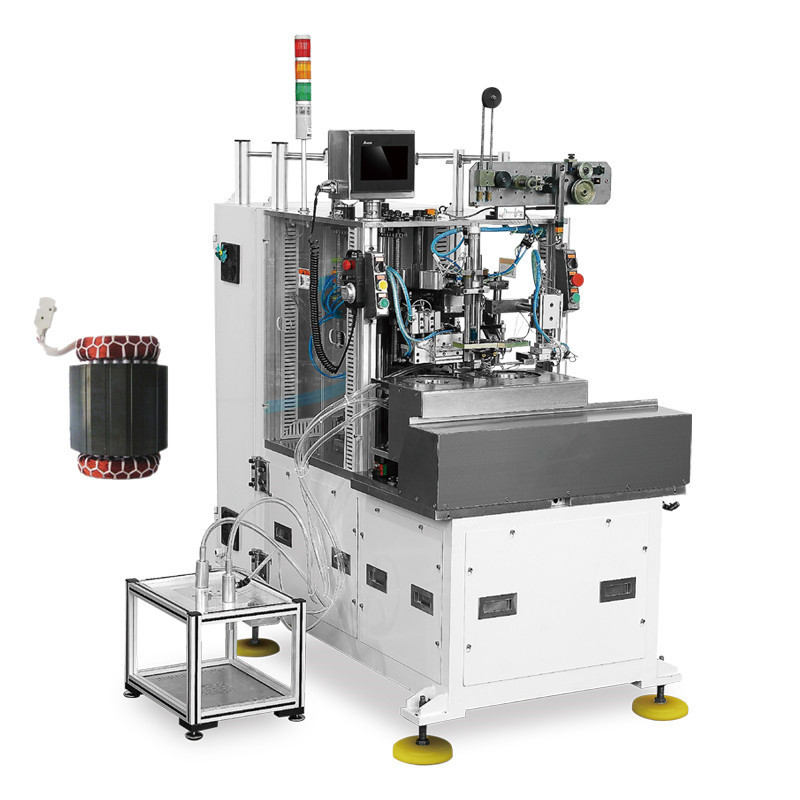

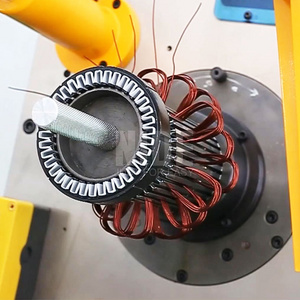

High Quality Automatic CNC 7-axis Controled Motor Stator Coil Lacing Machine Double Binding Machine

Features of this Servo double binding machine.

• Use machining center CNC7-axis numerical control system control, and use with man-machine interface.

• It has the characteristics of fast speed, high stability, accurate position and quick mold change.

• The machine is equipped with automatic stator height adjustment, stator positioning device, stator compression device, automatic wire feeding device, automatic thread trimming device, automatic thread suction device, and automatic wire break detection device.

• The working platform that moves left and right saves the time of removing the stator during automatic operation, thereby greatly improving the overall efficiency.

•This machine is particularly suitable for binding long-lead motors and automating the production line of long-lead motors.

• This model is equipped with an automatic thread hooking device, which has the functions of automatic knotting, automatic thread trimming, and automatic thread suction.

• The unique patented design of the dual track cam is adopted, which does not hook the grooved paper, does not damage the copper wire, does not lint, does not miss the binding, does not damage the binding line and the binding line does not cross.

• The automatic refueling system is controlled to ensure the quality of the equipment.

• Hand wheel precision adjustment, easy to debug and humane.

• The reasonable design of the mechanical structure makes the equipment run faster, less noise, longer life, more stable performance, and easier to maintain

Parameters:

| Product name | Servo double binding machine |

| Model | LBX-D1 |

| Working head | 1 |

| Working station | 2 |

| Maximum stator outer diameter | 160MM |

| stator inner diameter | >=30MM |

| Applicable stator stack thickness | 8-150MM |

| Transposition time | 0.5s |

| Lashing method | slot by slot, slot by slot, fancy lashing |

| Lashing speed | 24 slots ≤ 14S (without knotting 10S) |

| Air pressure | 0.5-0.8MPA |

| Power | 3KW |

| Power supply | 380V three-phase four-wire system 50/60Hz |

| Weight | 1100KG |

| Size | (L) 1650* (W) 950* (H) 1700 |