- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1-100t

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support, Video technical support

-

product name:

-

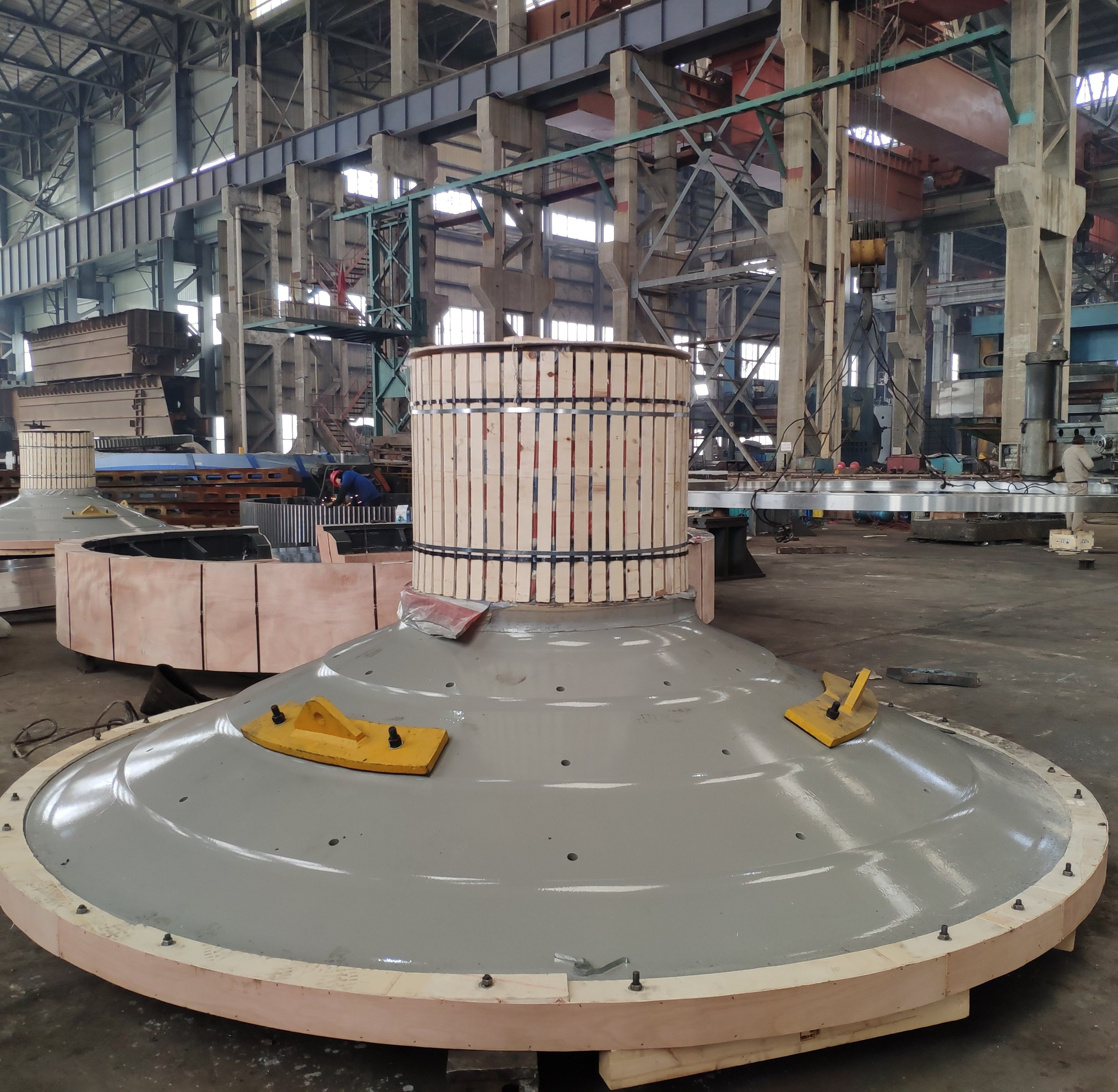

Duty Cnc Lathe Machining Cement Casting Steel End Cap Ball Mill Cover

-

Module:

-

12-70

-

Diameter:

-

300-16000

-

Gear accuracy:

-

According to drawings

-

Color:

-

According to requirements

-

Inspection:

-

Third party approved

-

Applicable standard:

-

ISO,AGMA,DIN,JIS,GB,

-

Certificate:

-

ISO9001:2008

-

Advantage:

-

Wear Resistant

-

Certification:

-

ISO9001

Quick Details

-

Capacity(t/h):

-

1-50

-

Place of Origin:

-

China (Mainland)

-

Brand Name:

-

zhongding

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1-100t

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support, Video technical support

-

product name:

-

Duty Cnc Lathe Machining Cement Casting Steel End Cap Ball Mill Cover

-

Module:

-

12-70

-

Diameter:

-

300-16000

-

Gear accuracy:

-

According to drawings

-

Color:

-

According to requirements

-

Inspection:

-

Third party approved

-

Applicable standard:

-

ISO,AGMA,DIN,JIS,GB,

-

Certificate:

-

ISO9001:2008

-

Advantage:

-

Wear Resistant

-

Certification:

-

ISO9001

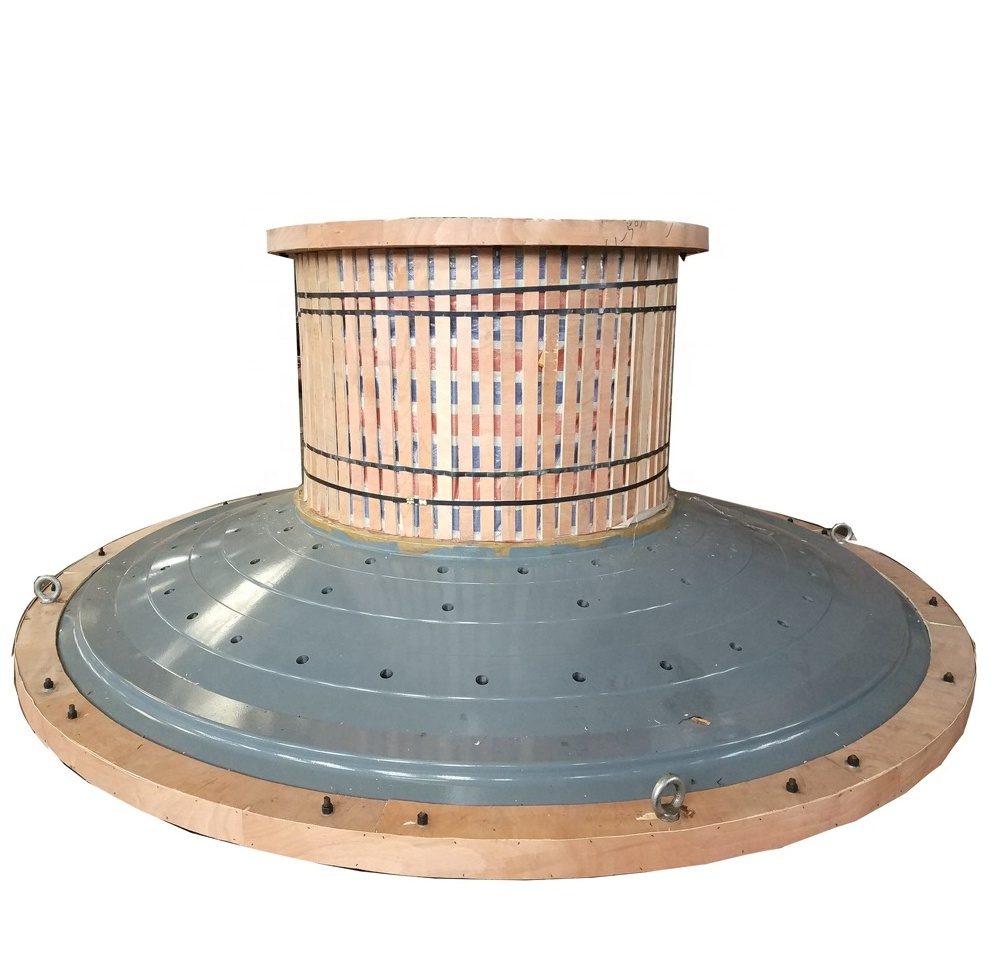

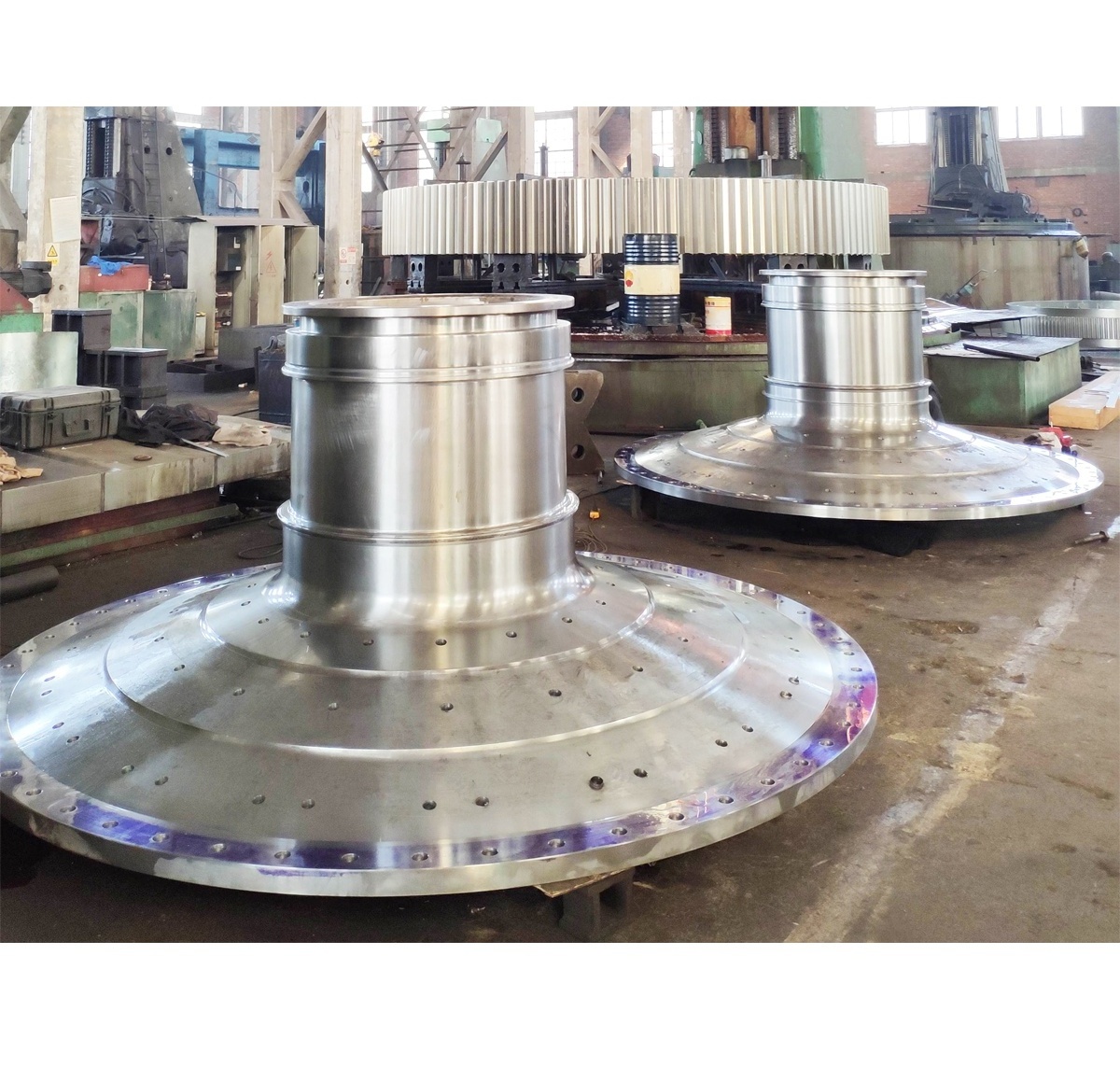

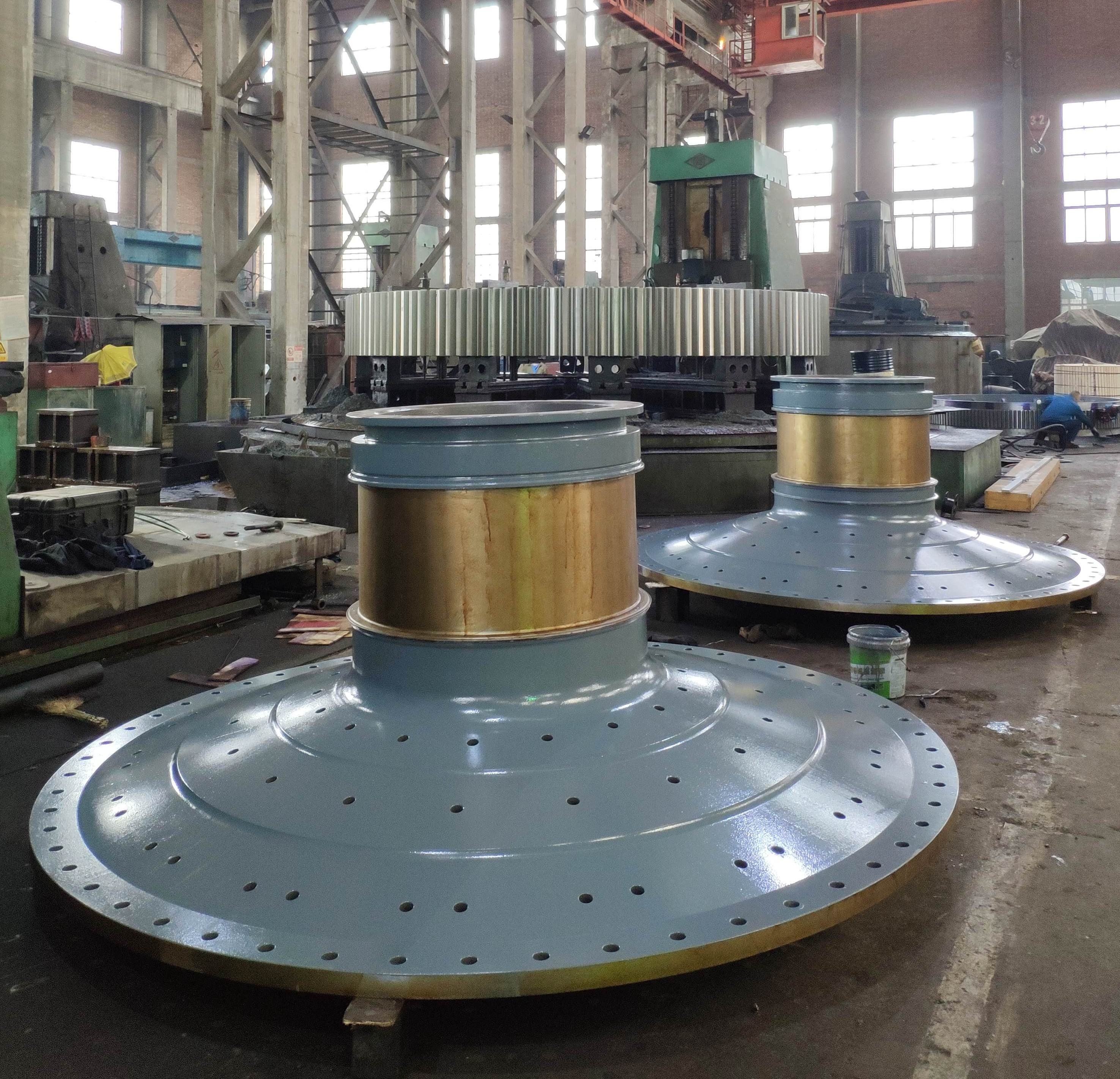

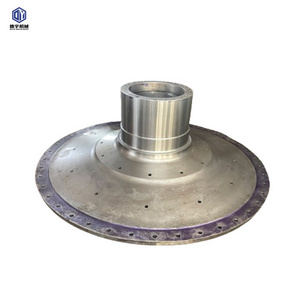

Customized Casting Steel End Cap Ball Mill Cover

Customized Casting Steel End Cap Ball Mill Cover

Our predominant products: large module girth gear/gear ring, pinion, pinion shaft, rolling ring tyre, end cover, mill head, flange, and other relative products.

Our essential equipments:

| Essential Equipment | Brand & Model No. | Quantity |

| CNC Vertical Lathe | D15160,D15120,D15100,SMVT800X31/50,DVT500X31/32 | 8 |

| Heavy Duty Vertical Lathe | 15110,1580,1563,1540 | 6 |

| CNC Hobbing Machine | D5316,D5314,D5310,D5308,D5305,D5304 | 7 |

| Hobbing Machine | 5380,5343,5353,ZFWZ50, | 4 |

| Double Helical Gear Milling Machine | DXC12,DXC10,DXC08,DXC06 | 6 |

| Floor Mounted Boring and Milling Machine | W260,WD250,WD220,265B,TX6213A,2636 | 7 |

| Heavy Duty Horizontal Lathe | W2010, Ø2000*10000mm | 1 |

| Drilling Machine | Z30100, Ø100*3150mm | 1 |

| Bevel Gear Planing Machine | ZSTTK, Y2380,F2320 | 3 |

| Bridge Cranes | 100MT,150MT,260MT | 10 |

| Gantry Crane | 40MT | 2 |

QUALITY CONTROL:

We have the advanced casting equipment, strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system, to ensure the reliable quality and long service life of large diameter metal ring gears.

QA DOC:

Chemical Composition Report, Mechanical Properties Report, UT Report, Heat Treatment Report, Dimensions Check Report

The data on chemical composition report and mechanical properties report are approved by third party

UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.

Heat Treatment Report: provide original copy of heat treatment curve/time table.

| Testing Device | Brand & Model No. | Quantity |

| Micrometer Tester | 1.2m, 1.6m, 3m | 11 |

| Inside Micrometer | 6m | 2 |

| Angle Gauge | No information | 5 |

| Ultrasonic Flaw Detector | CTS-22A | 1 |

| Hardness Tester | MH320, HLN-11A | 1 |

| Magnetic Tester | CJE-12/220 | 1 |

| Roughness Tester | TR200 | 1 |

PACKING&DELIVERY

Packaging Details: Anti-rust surface protection, non-fumigation wooden case OR per customer's requirement

Delivery Detail: 90-180days according to the order

Production capacity:

| Product Name | Production Line Capacity | Actual Units Produced (Previous Year) |

| Gear and Gear Shaft | 8000 Tons Per Year | 6300 Tons |

| Mining Machinery Parts | 10000 Tons Per Year | 7500 Tons |

| Casting and Forging | 10000 Tons Per Year | 9000 Tons |

| Process&Technology of Steel Castings | |

| Item | Introduction |

| Process | Sand Casting |

| Machining | rough machining, semi-finished machining, finished machining |

| Test | Chemical composition, mechanical property, UT,MT |

| Heat Treatment | Normalized, Normalized and Tempered, Quench and Tempered |

Nowadays our products can be found in many places worldwide, like West Europe, South America, Middle East, Australia, Southeast Asia.

Luoyang Zhongding Heavy-Duty Machinery Co., Ltd. is located in Luoyang, the famous heavy industry base in China, is in the field of mines, metallurgy, building materials, nonferrous metals, chemicals, machinery and other industrial customers to provide technical equipment and engineering design of the professional enterprise.

Company was founded in 1991, the total area of 48000 square meters, the existing staff of 255 people, including senior engineering and technical personnel 69 people.

The company has complete testing equipment and testing means, and based on ISO9001: 2000 standard established a perfect quality management system, on the formation of the quality of the products in the whole process control to ensure that the user's quality requirements are fully guaranteed.