- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

4.3 kN

-

Theoretical Shot Volume(cm³):

-

700 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

165 g

-

Screw diameter (mm):

-

150 mm

-

Distance between Tie Bars:

-

150mm

-

Weight (KG):

-

3500 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

700 mm

-

Model Number:

-

TYM-W4545

-

Brand Name:

-

TYM

-

Power (kW):

-

12.1 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Ejection stroke:

-

150mm

-

Tie-bars space:

-

450*450mm

-

Motor Power:

-

12.1KW

-

machine weight:

-

3.5T

-

Clamping force:

-

130T

-

Shot volume:

-

165g

-

Injection rate:

-

30g/s

-

Marketing Type:

-

New Product 2021

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

130mm

-

Distance between Tie Bars(Height)(mm):

-

130mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

4.3 kN

-

Theoretical Shot Volume(cm³):

-

700 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

165 g

-

Screw diameter (mm):

-

150 mm

-

Distance between Tie Bars:

-

150mm

-

Weight (KG):

-

3500 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

700 mm

-

Model Number:

-

TYM-W4545

-

Brand Name:

-

TYM

-

Power (kW):

-

12.1 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Ejection stroke:

-

150mm

-

Tie-bars space:

-

450*450mm

-

Motor Power:

-

12.1KW

-

machine weight:

-

3.5T

-

Clamping force:

-

130T

-

Shot volume:

-

165g

-

Injection rate:

-

30g/s

-

Marketing Type:

-

New Product 2021

silicone car wire plug wire LSR overmolding custom silicone cable making machine OEM

Horizontal Liquid Silicone Rubber (LSR) injection molding machine

D irect pressure mould opening and closing system, horizontal injection structure, it can adjust the mould faster, and control the position more precisely. I t is more suitable for producing the LSR parts which can be automatically remo ved from the mould.

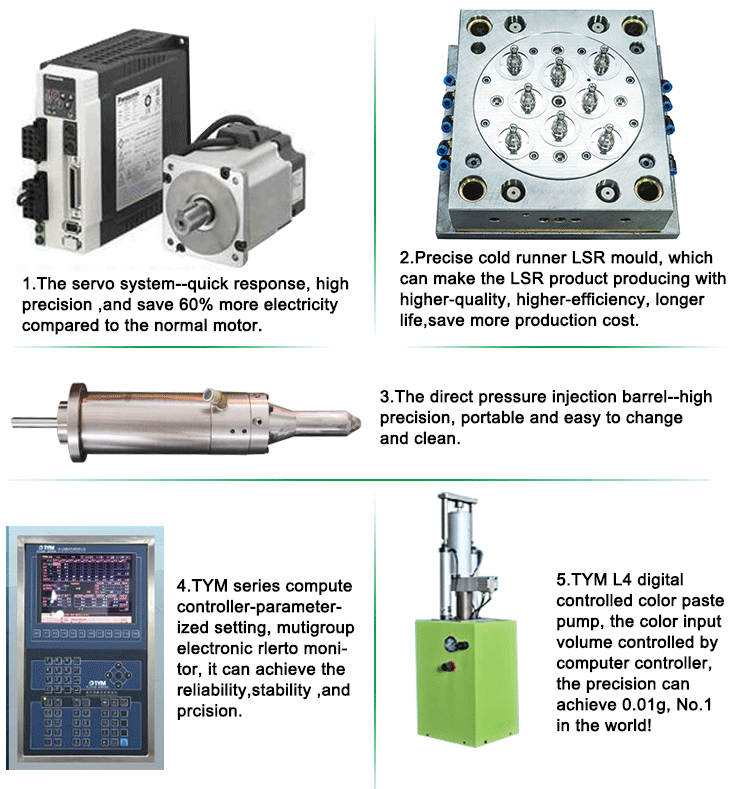

T he main feature of the horizontal LSR molding machine:

A. N ewly-optimized integrated all-in-one design.

B. Meet multiple requirements on the automatic manufacturing technique for LSR products.

C. S horter the mould closing and opening time, improve the production efficiency.

D. R emote control function.

E. M ulti-section mould closing and opening and injection, speed adjusting stepless.

|

ITEM |

DESCRIPTION |

UNIT |

TYM-W4040 |

TYM-W4545 |

TYM-W5050 |

TYM-W5555 |

|

Injection Unit |

Shot Volume |

g |

165 |

165 |

300 |

300 |

|

Injection Rate |

g/s |

30 |

30 |

30 |

30 |

|

|

Injection Pressure |

Kg/cm2 |

700 |

700 |

700 |

700 |

|

|

Clamping Unit |

Clamping Force |

T |

120 |

130 |

150 |

160 |

|

Opening Stroke |

mm |

200-700 |

200-700 |

200-700 |

200-700 |

|

|

Tie-Bars Space |

mm |

400*400 |

450*450 |

500*500 |

550*550 |

|

|

Ejection Force |

T |

4.3 |

4.3 |

4.3 |

4.3 |

|

|

Ejection Stroke |

mm |

150 |

150 |

150 |

150 |

|

|

Pump Pressure |

Mpa |

21 |

21 |

21 |

21 |

|

|

Others |

Motor Power |

KW |

12.1 |

12.1 |

12.1 |

12.1 |

|

Machine Weight |

T |

2.8 |

3.5 |

4.1 |

4.9 |

|

|

Machine Dimension |

m |

4.1*1.5*1.95 |

4.1*1.6*2.0 |

4.1*1.6*2.3 |

4.2*1.6*2.4 |