- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, 200*160*60mm

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Voltage:

-

220/380/440v

-

Dimension(L*W*H):

-

2100*1550*2650mm

-

Weight (KG):

-

430 kg

-

Types:

-

Vibration hydraulic brick machine

-

Brick raw materials:

-

concrete, cement, sand, gravel, fly ash, construction waste

-

Forming method:

-

hydraulic + vibration

-

The main form of vibration:

-

desktop molded vibration

-

Vibration frequency:

-

2800-4500 (r/min)

-

Mould:

-

customized according to customer needs

-

Molding cycle:

-

15s

-

Machine material:

-

Q235R steel

-

Power:

-

22.5-67.5KW

-

aftersale service provided:

-

Engineers available to service machinery overseas

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement,FLY ASH,Cinder,Sand,Coal Gangue,Crushed Stone

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 100000 to 300000 square meters per year

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, 200*160*60mm

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Voltage:

-

220/380/440v

-

Dimension(L*W*H):

-

2100*1550*2650mm

-

Weight (KG):

-

430 kg

-

Types:

-

Vibration hydraulic brick machine

-

Brick raw materials:

-

concrete, cement, sand, gravel, fly ash, construction waste

-

Forming method:

-

hydraulic + vibration

-

The main form of vibration:

-

desktop molded vibration

-

Vibration frequency:

-

2800-4500 (r/min)

-

Mould:

-

customized according to customer needs

-

Molding cycle:

-

15s

-

Machine material:

-

Q235R steel

-

Power:

-

22.5-67.5KW

-

aftersale service provided:

-

Engineers available to service machinery overseas

|

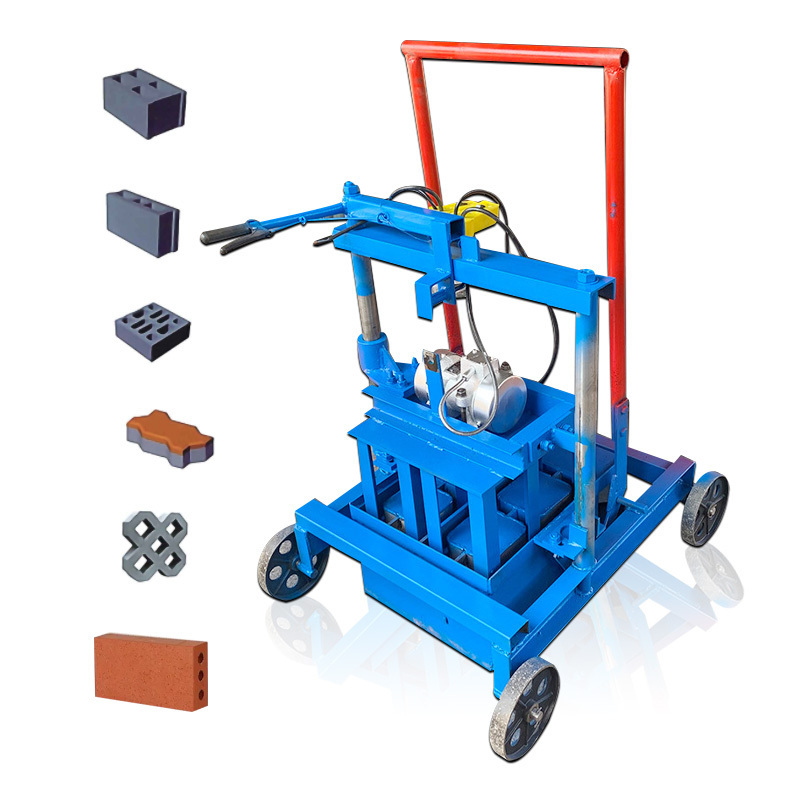

Factory Directly Supply Automatic Brick Making Machine Block Hollow Block Brick Making Machine For Paving Road

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Product Description

Factory Directly Supply Automatic Brick Making Machine Block Hollow Block Brick Making Machine For Paving Road

one kind of concrete block making machine in our company . It is mainly used in building , bridges , roads . Can make solid block , hollow block by changing the molds . Very popular in the country which need for construction .

fly ash bricks press making machine

is controlled by PLC programed in computer, fully automatic, high production efficiency, meanwhile the labor strength of workers is low. And the compactedness as well as quality uniformity of concrete products is good. It produces various cement blocks such as hollow blocks, paving bricks, solid bricks, grass blocks and so on by changing the block molds.

1.The rack is manufactured using high strength with special welding technique, it resists vibrating shock. 2.It adopts multiaxis synchronizer vibration mode to ensure vertically downward to reach best vibration effect. 3.The long-period over length guide bearing guarantees the accurate movement between upper mould and mould box.

4.Multiaxis forced mixer system has better adaptability to raw materials with different nature.

5.Hydraulic system which is well-designed has high thermal efficiency and low heat productivity, so that it ensures its high reliability.

6.the other is equipped with electronic feeding silo, hydraulic automatic off-board machine, etc., for the user to achieve fullautomation.

6.the other is equipped with electronic feeding silo, hydraulic automatic off-board machine, etc., for the user to achieve fullautomation.

Raw Materials:

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

Uses: architecture, roads, squares, water conservancy, garden construction, etc. Products such as: exterior wall tiles, interior tiles, wall display blocks, floors, berm blocks, interlocking pavement blocks and curb stone pavers secondary color fabrics

Mold:By changing different molds, the brick making machine can produce different wall tiles, perforated bricks and solid bricks.Optional materials: pigments and chemical elements.

Specification

|

Model

|

200

|

|

The forming number

|

2~4 pcs/time

|

|

Work pressure

|

10.5Mpa

|

|

Brick specification (mm)

|

390*100*190mm, 4pcs/time, 1800pcs/time

390*120*190mm, 3pcs/time, 1300pcs/shift

390*150*190mm, 3pcs/time, 1300pcs/shift

240x190*190mm, 2pcs/time, 920pcs/shift

390x190x190mm, 2pcs/time, 900pcs/shift

240x115x53mm, 12pcs/time, 5700pcs/shiftand other brick size as your request...

|

|

Forming cycles (S )

|

50-60 S/time

|

|

Power

|

1.1-1.5kw motor / 8hp diesel engine

|

|

Capacity per 8 hours

|

1000~1200pcs/8hr

|

|

Dimension

|

920*800*1258mm

|

|

Net weight/ gross weight

|

165kg/220kg

|

Customer Sites

Hot Searches