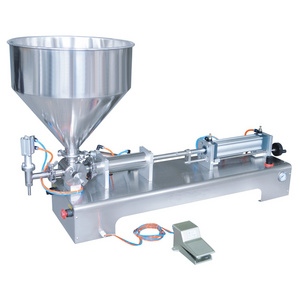

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Place of Origin:

-

China

-

Brand Name:

-

YUHANG

-

Weight:

-

50 KG

-

Filling speed:

-

20-40 b/min

-

Control:

-

Button

-

Filling nozzles:

-

1 Nozzle/2 Nozzles

-

Filling volume:

-

5-60ml;10-120ml;25-250ml ;50-500ml ;100-1000ml

-

Machine material:

-

Stainless Steel SUS 304

-

Filling accuracy:

-

±1%

-

Hopper size:

-

30L

-

Air pressure:

-

0.5-0.7MPa

-

Operation:

-

Foot Pedal Operation

Quick Details

-

Machinery Capacity:

-

1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Place of Origin:

-

China

-

Brand Name:

-

YUHANG

-

Weight:

-

50 KG

-

Filling speed:

-

20-40 b/min

-

Control:

-

Button

-

Filling nozzles:

-

1 Nozzle/2 Nozzles

-

Filling volume:

-

5-60ml;10-120ml;25-250ml ;50-500ml ;100-1000ml

-

Machine material:

-

Stainless Steel SUS 304

-

Filling accuracy:

-

±1%

-

Hopper size:

-

30L

-

Air pressure:

-

0.5-0.7MPa

-

Operation:

-

Foot Pedal Operation

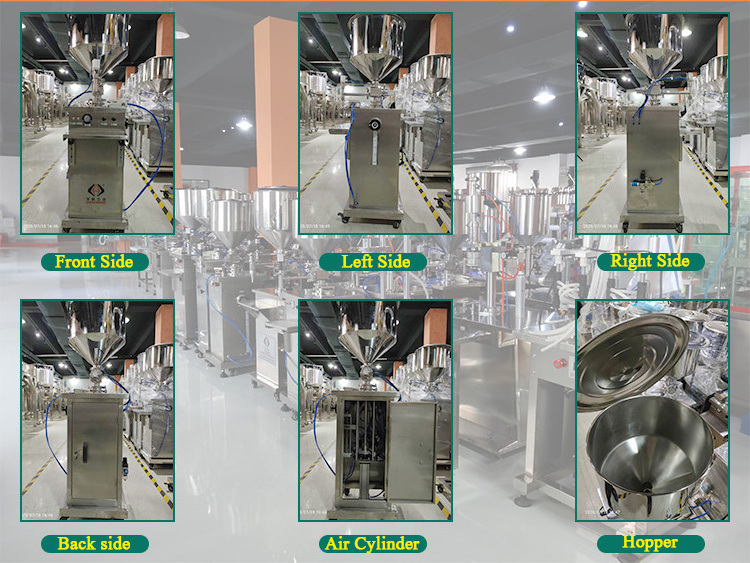

Product pictures

Products Description

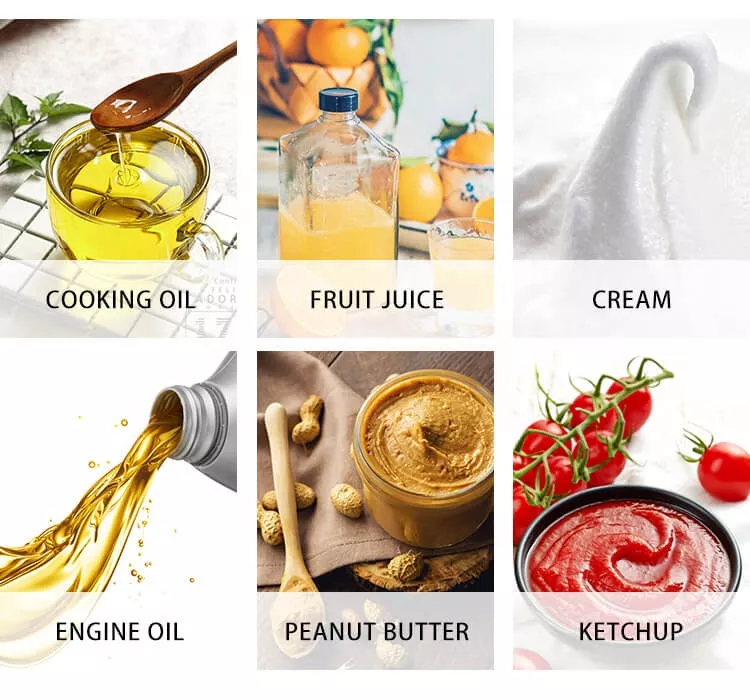

The filling machine is designed specially by Yuhang company in order to suitable for different viscosity liquid, cream and paste material in all kinds industries such as shampoo, liquid soap, detergent, oil, toothpaste, gel, BB cream, skin care, foundation cream, soy sauce, wine and water etc. Its design aims to meet different demand from customer caused by labor investment, cost, operating method and product requirement etc.

Main Features

1.This machine adopts imported parts, piston and cylinder which made of stainless steel and polytetrafluoroethylene. Excellent qualified imported components and perfect mechanical design ensure its leading position among domestic similar machine.

2.The new vertical design that load less area, light and easy to operate

2.The new vertical design that load less area, light and easy to operate

3.Switch function between manual and automatic: when turning to “automation” , machine will fill continuously with setting speed and capacity; when turning to “manual” , operator step on footplate to finish filling with setting capacity but if stepping footplate continuously, it also will consecutively fill.Cylinder and three-way use cuff connection which is easy to disassemble so that it is easy to clean

4.Anti-leaking filling system:the closure head is moved when the air cylinder moves up an down during filling. When the closure head down by air cylinder, then valve will open and start to fill material; when it up by air cylinder, the valve will close and stop to fill and avoid leaking and wire drawing

4.Anti-leaking filling system:the closure head is moved when the air cylinder moves up an down during filling. When the closure head down by air cylinder, then valve will open and start to fill material; when it up by air cylinder, the valve will close and stop to fill and avoid leaking and wire drawing

Technical Specifications

|

Model

|

YH

|

|

Air Pressure

|

0.6- 0.7MPa

|

|

Pressure of Reducing Valve

|

0.55-0.65MPa

|

|

Air Consumption

|

0.3 m³/min

|

|

Capacity

|

20-40 b/min

|

|

Filling Range

|

5-60ml;10-120ml;25-250ml ;50-500ml ;100-1000ml

|

|

Precision

|

±1%

|

|

Material

|

SS 304L/SS316L

|

|

Heating system

|

Heating system

|

|

Filling nozzle

|

1 nozzle

|

Product details

Product Application

They are suitable to fill water, beverage, oil, ink, lotion, shampoo, sauce, jam, gel, cream, etc in the field of cosmetic,drinks, chemical, medical, food, etc.

Hot Searches