- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2024

-

Voltage:

-

380

-

Dimension(L*W*H):

-

1740*810*1830

-

Motor Power (kW):

-

5.5

-

Weight (T):

-

1.8

Quick Details

-

Nominal Force (kN):

-

630

-

Place of Origin:

-

anhui

-

Brand Name:

-

Daramco

-

Year:

-

2024

-

Voltage:

-

380

-

Dimension(L*W*H):

-

1740*810*1830

-

Motor Power (kW):

-

5.5

-

Weight (T):

-

1.8

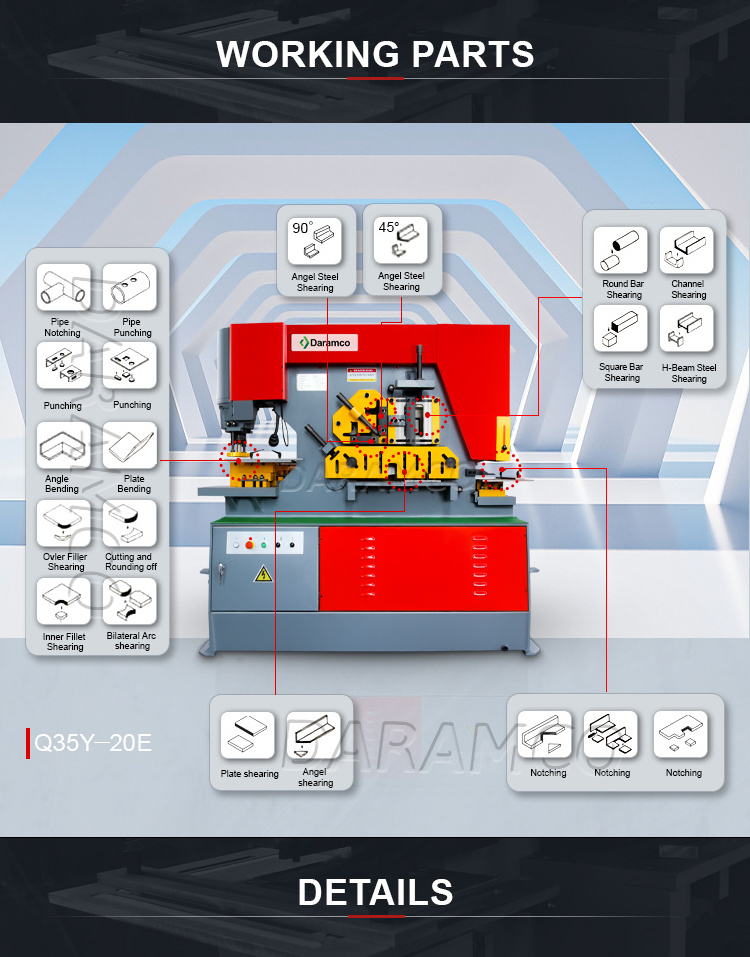

Q35Y Series Ironworker are an ideal equipment for cutting all kinds of angle steel, I-beam,

U-shape steel, right angle or 45 degree angle steel. Multi-workstations make it possible

to finish series operations simultaneously on one machine, such as punching, shearing

and notching. Dual-position-type combined punching and shearing machine allows

two-man operation at the same time (stamping +another work station).

1. A full range of punches and dies are available for various punching needs.

2. Quick change retaining nut system for fast punch tooling change.

3. Thoughtfully designed stripper for visibility, safety and ease of use.

4. A large 2-piece table with scales and gauging stops is standard on all models.

5. Stripper with interchangeable plates of various openings to minimize deformation

is standard on all models.

DARAMCO can provide different sizes of punched and dies are available,customers can also choose different types from the catalog.

Louver Punching function shares the same position with hole punching function,it can

form the Louvers step by step.

1. Single shear with no material loss and minimal deformation.

2. 45° miter-cut is easy and clean.

3. Stationary blades with fourusable cutting edges.

4. Selectable corner radii on moving blades for optimum results on small or large angles.

1. One hold-down for various sizes of square bar shearing and round bar shearing.

2. Optional channel and section bar shear tooling is available for most models.

(See specification chart for details)

1. Specially machined upper blade to give a clean shear with minimum distortion.

2. Lower blade has four usable cutting edges.

3. Variable degree miter-cutting on angle flange.

4. Easily adjustable hold-down.

5. Support table with guides for accuratepositioning.

1. Ideal for notching of flat bars and angles.

2. Electrically interlocked safety guard for maximum safety and visibility.

3.Gauging table included with stops for precise positioning.

|

Model

|

Q35Y-12

|

Q35Y-16

|

Q35Y-20

|

|

Punching Pressure (T)

|

35T

|

60T

|

90T

|

|

Max.cutting thickness of steel plates (mm)

|

12

|

16

|

20

|

|

Material strength (N/m㎡)

|

≤450

|

≤450

|

≤450

|

|

Angle of Shear(°)

|

7°

|

7°

|

7°

|

|

Flat bar shearing (T×W) (mm)

|

12*160 6*300

|

16*250 8*400

|

20*330 10*480

|

|

Max.length of cylinder stroke (mm)

|

35

|

80

|

80

|

|

Trips frequency (times/min)

|

10-18

|

11-20

|

12-20

|

|

Depth of throat (mm)

|

115

|

300

|

355

|

|

Punch depth (mm)

|

12

|

16

|

20

|

|

Max.punching diameter(mm)

|

25

|

25

|

30

|

|

Motor Power (KW)

|

4

|

5.5

|

7.5

|

|

Overalldimensions (L×W×H) (mm)

|

950*550*1800

|

1740*810*1830

|

1950*900*1950

|

|

Model

|

Q35Y-25

|

Q35Y-30

|

Q35Y-40

|

Q35Y-50

|

|

Punching Pressure (T)

|

120T

|

160T

|

200T

|

250T

|

|

Max.cutting thickness of steel plates (mm)

|

25

|

30

|

40

|

50

|

|

Material strength (N/m㎡)

|

≤450

|

≤450

|

≤450

|

≤450

|

|

Angle of Shear(°)

|

8°

|

8°

|

8°

|

8°

|

|

Flat bar shearing (T×W) (mm)

|

25*330 16*600

|

30*335 20*600

|

40*335 30*600

|

50*300 30*750

|

|

Max.length of cylinder stroke (mm)

|

80

|

80

|

100

|

100

|

|

Trips frequency (times/min)

|

8-18

|

6-16

|

6-16

|

6-12

|

|

Depth of throat (mm)

|

400

|

600

|

530

|

600

|

|

Punch depth (mm)

|

25

|

28

|

35

|

40

|

|

Max.punching diameter(mm)

|

35

|

38

|

40

|

45

|

|

Motor Power (KW)

|

11

|

15

|

18.5

|

18.5

|

|

Overalldimensions (L×W×H) (mm)

|

2355*960*2090

|

2800*1050*2450

|

2900*1100*2500

|

3200*1440*2500

|

Hot Searches