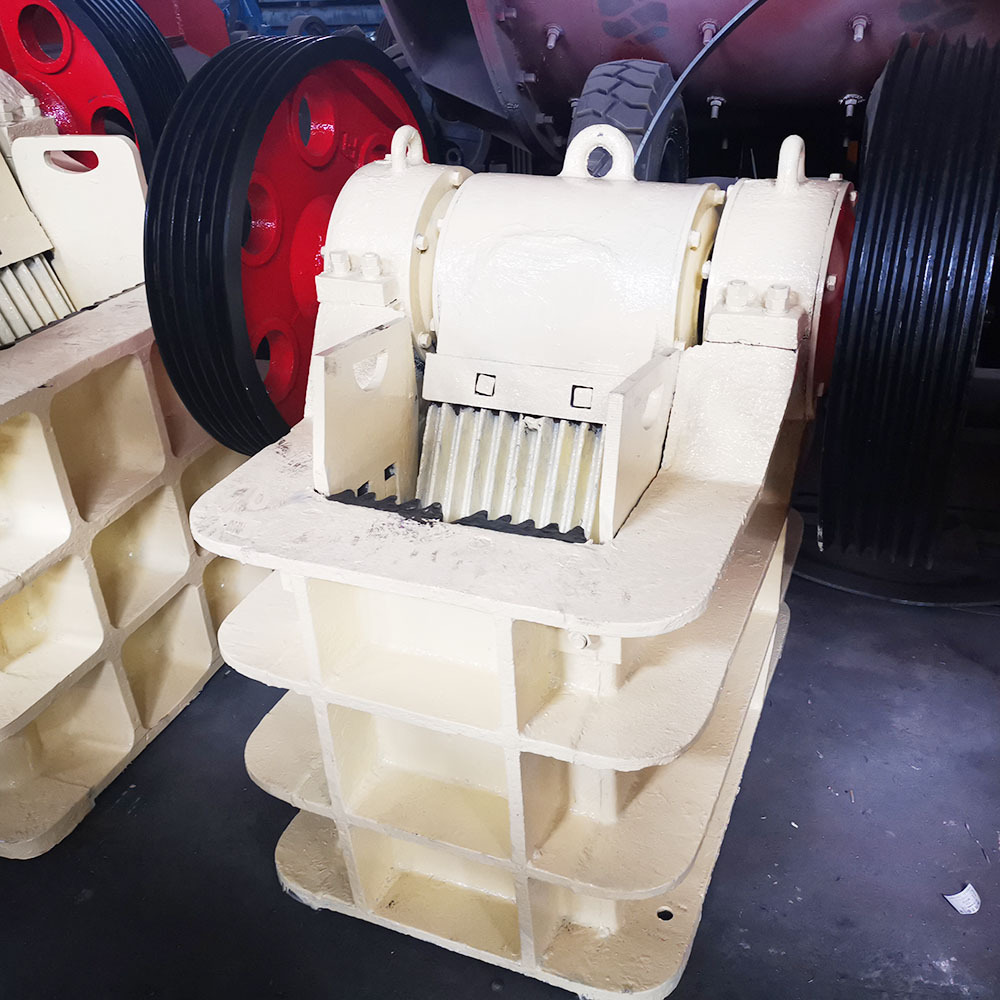

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Eastman

-

Dimension(L*W*H):

-

based on the model

-

Weight:

-

2000 KG

-

Product name:

-

jaw crusher machine

-

Installation:

-

Engineer Guide

-

Material:

-

Carbon Steel

-

The Machines classification:

-

Mining Equipment

-

Price:

-

Negotiatable

-

Quality:

-

Advanced Technology

-

Function:

-

Crushing Material

-

Factory visit:

-

Welcomed Warmly

-

Color:

-

various

-

Service:

-

in sale and after sale

Quick Details

-

Application:

-

Mining, metallurgy, building

-

Capacity(t/h):

-

16-60

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Eastman

-

Dimension(L*W*H):

-

based on the model

-

Weight:

-

2000 KG

-

Product name:

-

jaw crusher machine

-

Installation:

-

Engineer Guide

-

Material:

-

Carbon Steel

-

The Machines classification:

-

Mining Equipment

-

Price:

-

Negotiatable

-

Quality:

-

Advanced Technology

-

Function:

-

Crushing Material

-

Factory visit:

-

Welcomed Warmly

-

Color:

-

various

-

Service:

-

in sale and after sale

Product Description

Introduction

Jaw crusher adopts the processing principle of two jaw plates squeeze each other. It is usually used in the first step for a variety of ore rock crushing. All kinds of ores which compressive strength is not higher than 320Mpa can be one-time processed to moderate granularity. Often forms a complete set of sand production line with the cone crusher, impact crusher, sand making machine, etc. It is widely used in mining, metallurgy, chemical industry, building materials, electricity, water conservancy,

transportation and other fields.

transportation and other fields.

Suitable material:

Granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore, etc.

Granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore, etc.

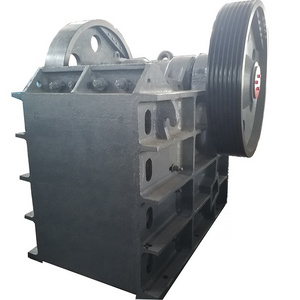

Principle of operation:

The working principle of jaw crusher is very simple. The whole crushing process rely on the relative motion of the two jaw plates. One of the jaw plates stay still while the other move against it. And with the movement, the materials between the two plates would be crushed into small elements. While the plates move against each other, the materials would be crushed and while plates move away from each other, the broken materials which are smaller enough would drop through the discharging opening. And due to the simple structure, gold mine jaw crusher is easy to maintain and repair. These features promote its popularity to a great extant.

The working principle of jaw crusher is very simple. The whole crushing process rely on the relative motion of the two jaw plates. One of the jaw plates stay still while the other move against it. And with the movement, the materials between the two plates would be crushed into small elements. While the plates move against each other, the materials would be crushed and while plates move away from each other, the broken materials which are smaller enough would drop through the discharging opening. And due to the simple structure, gold mine jaw crusher is easy to maintain and repair. These features promote its popularity to a great extant.

Parameters

|

Model

|

Inlet size

(mm) |

Feeding size (mm)

|

Output size (mm)

|

Capacity (t/h)

|

Power (kw)

|

Weight (t)

|

|

PE150×250

|

150×250

|

125

|

10-40

|

1-3

|

5.5

|

1.5

|

|

PE250×400

|

250×400

|

210

|

20-80

|

5-20

|

15

|

2.8

|

|

PE400×600

|

400×600

|

340

|

40-100

|

16-60

|

30

|

6.5

|

|

PE500×750

|

500×750

|

425

|

50-100

|

40-110

|

55

|

11.5

|

|

PE600×900

|

600×900

|

500

|

65-180

|

80-180

|

55-75

|

16

|

|

PE750×1060

|

750×1060

|

630

|

80-180

|

110-320

|

90-110

|

28

|

|

PE900×1200

|

900×1200

|

780

|

95-225

|

220-450

|

110-132

|

49

|

|

PE1200×1500

|

1200×1500

|

1020

|

150-300

|

400-800

|

160-220

|

100

|

|

PEX150×750

|

150×750

|

120

|

18-48

|

8-25

|

15

|

3.5

|

|

PEX250×1000

|

250×1000

|

210

|

25-60

|

16-52

|

30-37

|

6.5

|

|

PEX350×1200

|

350×1200

|

300

|

70-140

|

25-120

|

75

|

12.3

|

Performance characteristics:

1) Simple structure, convenient in use and maintenance. Stable performance, low operation cost, high crushing ratio.

2) Crushing cavity depth and no blind spot, increasing the feeding ability and capacity.

3) High crushing ratio, uniform product size.

4) Gasket type discharging mouth adjusting device, reliable, convenient and the adjust ingrange is big, increase the flexibility of

the equipment.

5) Lubrication system safe and reliable, easy to parts replacement, small maintenance workload.

6)Simple structure, reliable operation, low operating costs.

7)Energy saving: stand-alone energy saving 15% ~ 30%, the system energy saving more than double.

8)Discharging mouth wide adjustment range, can meet the requirements of different users.

9)Low noise, little dust.

1) Simple structure, convenient in use and maintenance. Stable performance, low operation cost, high crushing ratio.

2) Crushing cavity depth and no blind spot, increasing the feeding ability and capacity.

3) High crushing ratio, uniform product size.

4) Gasket type discharging mouth adjusting device, reliable, convenient and the adjust ingrange is big, increase the flexibility of

the equipment.

5) Lubrication system safe and reliable, easy to parts replacement, small maintenance workload.

6)Simple structure, reliable operation, low operating costs.

7)Energy saving: stand-alone energy saving 15% ~ 30%, the system energy saving more than double.

8)Discharging mouth wide adjustment range, can meet the requirements of different users.

9)Low noise, little dust.

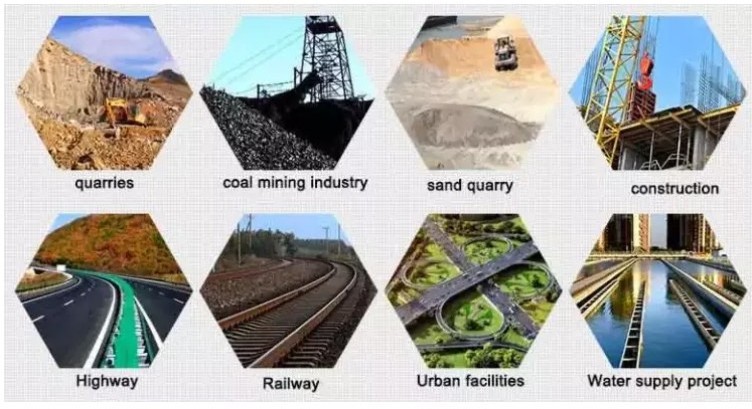

Applications

Jaw crusher often forms a complete set of sand production line with the cone crusher, counterattack crusher, sand making machine, etc. The flow chart below is a processing line indicating sand making .

Successful Cases

Product packaging and shipping

Company Introduction

Ganzhou Eastman Technology Co, Ltd

.

is a privatization enterprise, which focuses on mining equipment R&D,manufacturing and sales, the main products include sand and stone making equipment ,new type dry technology cement producing equipment,limestone producing equipment etc.

1. High productivity, high reliability and stable performance with small noise.

2. Energy-saving and low equipment operation cost.

3. Professional technical supports and design, sales service and after-sales service.

4.Simple structure and easy maintenance.

5.Competitive price.

factory

Our factory has an area of 10000 square meters, USD 1000 million fixed assets.Our engineer and technical personnel covering 15% of the total staff.

FAQ

Questions customers asked

1.Q:How is the quality of your products?

A: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Q:How about the Guaranteed?

A : All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.Q:How about price?

A: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Q:How about the service and payment terms?

A: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

A: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Q:How about the Guaranteed?

A : All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.Q:How about price?

A: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Q:How about the service and payment terms?

A: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches