- Product Details

- {{item.text}}

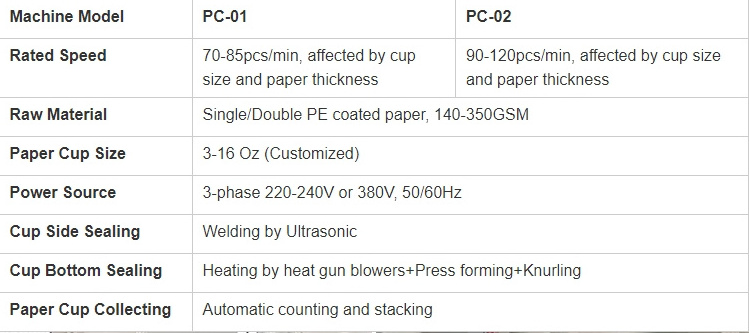

Quick Details

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

5kw

-

Dimension(L*W*H):

-

3400*1650*1400mm

-

Weight:

-

1400 kg

-

Product name:

-

paper cup machine

-

Raw material:

-

single and double PE coated paper

-

Working speed:

-

70-150pcs/min

-

Paper cup size:

-

3 ~ 16 Oz

-

Cup welding way:

-

ultrasonic welding

-

Cup bottom sealing:

-

hot press sealing

-

Cup collecting:

-

automatic

-

After-sales Service Provided:

-

Spare Parts Video Technical Support

-

Certificate:

-

CE, ISO

Quick Details

-

Production Capacity:

-

120 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

5kw

-

Dimension(L*W*H):

-

3400*1650*1400mm

-

Weight:

-

1400 kg

-

Product name:

-

paper cup machine

-

Raw material:

-

single and double PE coated paper

-

Working speed:

-

70-150pcs/min

-

Paper cup size:

-

3 ~ 16 Oz

-

Cup welding way:

-

ultrasonic welding

-

Cup bottom sealing:

-

hot press sealing

-

Cup collecting:

-

automatic

-

After-sales Service Provided:

-

Spare Parts Video Technical Support

-

Certificate:

-

CE, ISO

Product Description

2023 new design high speed automatic paper cup making machine disposable paper cup making machine low prices in India

High speed paper cup forming machine comes with two turnplate, open intermittent indexing cam mechanism and gear transmission, longitudinal axis structures.The machine comes with PLC control system, sensorfailure detecting, and can stop working automatically. If the machine has any problem, it can greatly improve operation safety and reducing labor cost.The machine can finish the whole process including paper feeding,side sealing, cup bottom punching& feeding, heating, knurling, cup-top curling, cup stacker. It is the best choice for making paper cups.

Specification

Details

1.

This paper cup automatic forming machine has the advantages of high performance, high efficiency and high quality.

2.

The indexing of the station plate adopts an open cam, and the advanced high-precision cam drive and gear. transmission make the forming of each station accurate.

3

.The maintenance and lubrication are more convenient and simpler than the closed splitter. The transmission parts in the machine have large space, easy to operate and maintain, and are superior to similar products on the market in all aspects.

4.

Servo tracking bottom feeding paper ensures the size of the cup bottom paper, ensures the size of the cup bottom paper and effectively saves raw materials.

5.

The human-machine interface PLC system controls the stable operation of the whole machine for a long time.

6.

The reasonable setting of automatic counting cup collection table can replace the busy work of manual work.

7.

This paper cup automatic forming machine has over cup detection, cup tube forming detection, and automatic

shutdown alarm for faults. The process flow of the equipment is as follows: suction sheet → cup tube bonding → upper cup tube → upper cup bottom → preheating 1 → preheating 2 → bottom folding → knurling → curling → lower cup → receiving material.

shutdown alarm for faults. The process flow of the equipment is as follows: suction sheet → cup tube bonding → upper cup tube → upper cup bottom → preheating 1 → preheating 2 → bottom folding → knurling → curling → lower cup → receiving material.

Packing & Delivery

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

2. Polystyrene foam plate wrapped around.3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Hot Searches