Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TEREK

-

Model Number:

-

LDD Series

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

100MPA

-

Cable Length:

-

hydraulic hose

-

Outlet Size:

-

1/2 NPT

-

Power:

-

0, Pneumatic

-

Theory:

-

Reciprocating Pump

-

Standard or Nonstandard:

-

Standard

-

Product name:

-

Air driven liquid pressurize pump

-

Material:

-

Stainless Steel 304

-

Feature:

-

High Flow

-

Type:

-

Self-priming Pump

-

Fuel:

-

Air driven

Quick Details

-

Application:

-

Automotive Industry, Industrial Utilities, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry

-

Pressure:

-

100MPA, High Pressure

-

Voltage:

-

0

-

Brand Name:

-

TEREK

-

Model Number:

-

LDD Series

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

100MPA

-

Cable Length:

-

hydraulic hose

-

Outlet Size:

-

1/2 NPT

-

Power:

-

0, Pneumatic

-

Theory:

-

Reciprocating Pump

-

Standard or Nonstandard:

-

Standard

-

Product name:

-

Air driven liquid pressurize pump

-

Material:

-

Stainless Steel 304

-

Feature:

-

High Flow

-

Type:

-

Self-priming Pump

-

Fuel:

-

Air driven

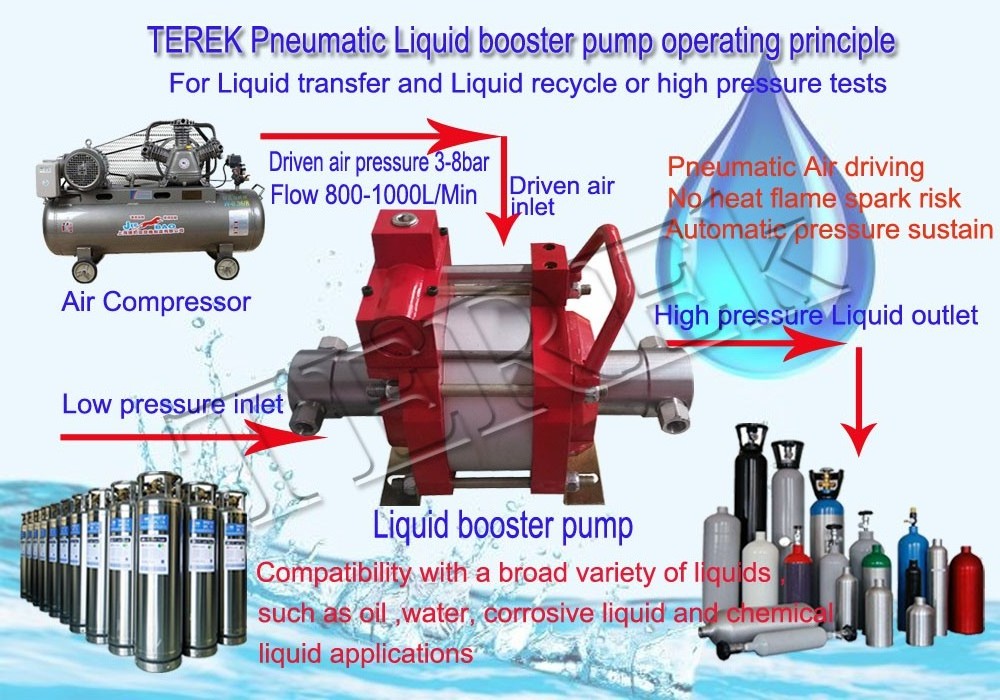

Maximum 6400 bar high pressure pneumatic grease pump for liquid/chemical/water/oil

TEREK pump adopt aluminum alloy and stainless steel materials , We offer the most complete range of models in the industry measured Such as :Capability of ultimate pressure, flow or output horsepower. Compatibility with a broad variety of liquids ,such as oil ,water, corrosive liquid and chemical liquid applications. High quality seals, long service life available.. LDD Series are double acting and single driven head type. They have less pulsations and deliver approx 50% more flow than the single acting LKD pumps The diameter of drive plunger is 160mm

TEREK pumps are self priming. In general it is not necessary to use an air line lubricator. The liquid to be pumped flows into the suction chamber by the up-stroke of the drive piston. By this suction effect, the inlet check valve is opened and the outlet check valve is closed. The down-stroke generates the pressure at the liquid side. The inlet check valve is closed and the outlet check valve is opened by the generated pressure. Liquid pumps cycle automatically, As the pressure increases, the cycle slows down., The pump stops automatically when the output pressure forces are equal. The pump restarts with a slight drop in the outlet pressure or an increase in the air drive pressure. Pump performance can be affected by a number of conditions, such as freezing of muffler or pilot valves (which is caused by moisture in air lines), Insufficient gas pressure in air inlet and dirty filers.

TEREK pump adopt aluminum alloy and stainless steel materials ,which depends on different medium liquid. Materials of stainless steel, make them an excellent choice of water application. High quality seals, long service life available. Compatibility with variety of liquids, such as oil, water and Other corrosive chemical liquids applications.

Obtain the maximum outlet pressure when the air drive pressure is 8bar/116Psi.

The rate of flow based on the air driven pressure is 6Bar (87psi) and the outlet pressure is 0 Bar. (It is approximate flow value.)

Approximate flow expect the air driven pressure is 6bar and an out pressure is 0bar.

Product advantages

1.Compressed Air driven - no electricity required

In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

2. High output pressure, No airline lubricator required

3. The pressure of the output liquid is easy to adjust, just adjust the input pressure.

4.Wide range of models with different ratios

5.Easy to install, operate and maintenance.

6. High quality seals, long life service available

Applications include

1,Hydrostatic pressure tests and blasting test for valves, pipe and tubes, pressure vessels, pressure switches, tanks, hoses, pipes and tubing, pressure gauges, cylinders and etc.

2.Safety valve and water pressure testing.

3.Automobile brake system and nozzle test.

4.Injection of chemical reagents in a pipe or other instruments

5. Pressure testing of high pressure liquid systems and instruments.

6. Performance test and calibration of instrument and meter.

How to Select Air Driven Liquid Boosters/Systems?

In order to choose the accurate and appropriate booster pump or systems for you,

Please kindly reply us the following questions:

1. What is the current pressure of the liquid ? ( )bar

2. What kind of liquid needs to be pressurized ? Such as oil ,water, corrosive liquid and chemical liquid ?

3.What is the output pressure of the liquid you want?( )bar

4.What is the driven air pressure ( Your air compressor) you can provide ?( )bar,

Because our booster pump is completely air driven and no need any electricity

5.How much of the outlet liquid flow rate do you need?( )L/min

6. What is its purpose or application field you used it? Thanks

1.Q : Are you manufacturer ?

A: Yes, We are the manufacturer with continuous and improved R&D. Production, Quality Check and service supply.

2.Q : Can I get your price list ?

A: Yes, Sure. In order to send you our available offered price. Please choose the products and let us know the product model and requirement in detail.

3.Q : Do you have stock for all items?

A:In general, we have some stock, while if you need a bulk order, we still need time to produce it. Of course, we will inform all details you before your payment.

4.Q : What is payment terms ?

A: Sample order : 100% full payment before start to production;

Large order : 30% deposit first, 70% pay after see the BL copy ;

5.Q: Can give free sample ?

A : Free : if small spare parts and the cost not too much is ok ;

Not Free : the cost expensive and all the machine can not be free ;

6.Q : How long can be finished the goods ?

Delivery date: 5-30 working days after deposit paid

Two years warranty, when the products reach to destination.