- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tongjia Machienry

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

22*2.3*m--42*3.5*3m

-

Power (kW):

-

85

-

Weight:

-

8.5

-

Name:

-

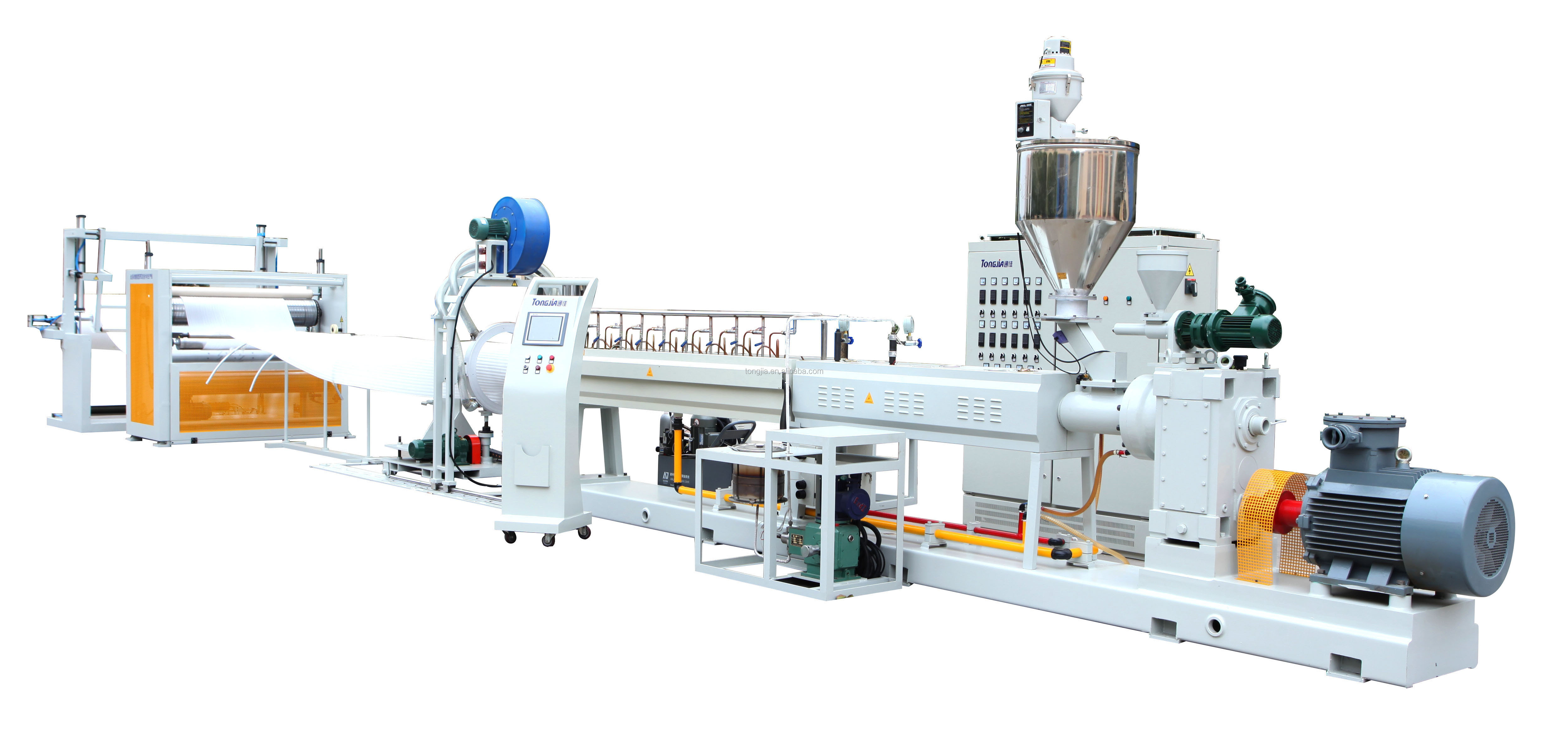

Heat Preservation EPE Foam Board Extruded Machine

-

Installed Capacity:

-

85-385 KW

-

Thickness of board mm:

-

1000-3000 mm

-

Cooling Method:

-

Cooled by Wind and Water

-

Width of product:

-

0.5-30 mm

-

Output(approx):

-

70-850 Kg

-

Foam rate:

-

30-60times

-

Power(W):

-

85-385KW

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

50:1

-

Screw diameter (mm):

-

150 mm

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tongjia Machienry

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

22*2.3*m--42*3.5*3m

-

Power (kW):

-

85

-

Weight:

-

8.5

-

Name:

-

Heat Preservation EPE Foam Board Extruded Machine

-

Installed Capacity:

-

85-385 KW

-

Thickness of board mm:

-

1000-3000 mm

-

Cooling Method:

-

Cooled by Wind and Water

-

Width of product:

-

0.5-30 mm

-

Output(approx):

-

70-850 Kg

-

Foam rate:

-

30-60times

-

Power(W):

-

85-385KW

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Marketing Type:

-

Ordinary Product

Products Description

Product Information

Polyethylene foamed sheet/film, also named as pearl cotton, is a kind of new-type packing material with the features of dampproof, shockproofi ng, sound insulation, heat preservation and good plasticity. It is an ideal substitute of traditional packing materials and used widely in the packing of electronic product, daily necessities, glass, pottery, electrical household appliances, spraying, furniture, hardware product, toy, etc.

Main Technical Specification

|

Model

|

Extruder

|

Output (approx)

|

Foam rate

|

Width of product

|

Thickness of product

|

Cooling method

|

Installed capacity (approx)

|

|

JG-FPM90

|

Φ90/55

|

70-90

|

30-60

|

1000-1400

|

0.5-4.0

|

Cooled by wind and water

|

85

|

|

JG-FPM105

|

Φ105/55

|

100-130

|

30-60

|

1000-1600

|

0.5-5.5

|

Cooled by wind and water

|

90

|

|

JG-FPM120

|

Φ120/55

|

140-170

|

30-60

|

1000-1600

|

0.8-6.5

|

Cooled by wind and water

|

115

|

|

JG-FPM135

|

Φ135/55

|

200-220

|

30-60

|

1000-1800

|

1.0-8.0

|

Cooled by wind and water

|

155

|

|

JG-FPM150

|

Φ150/55

|

320-360

|

30-60

|

1000-2000

|

2.0-12.0

|

Cooled by wind and water

|

180

|

|

JG-FPM180

|

Φ180/55

|

450-520

|

30-60

|

1000-3000

|

3.0-16.0

|

Cooled by wind and water

|

260

|

|

JG-FPM200

|

Φ200/55

|

550-650

|

30-60

|

1000-3000

|

3.0-25.0

|

Cooled by wind and water

|

340

|

|

JG-FPM250

|

Φ250

|

600-850

|

30-60

|

1000-3000

|

5.0-30.0

|

Cooled by wind and water

|

385

|

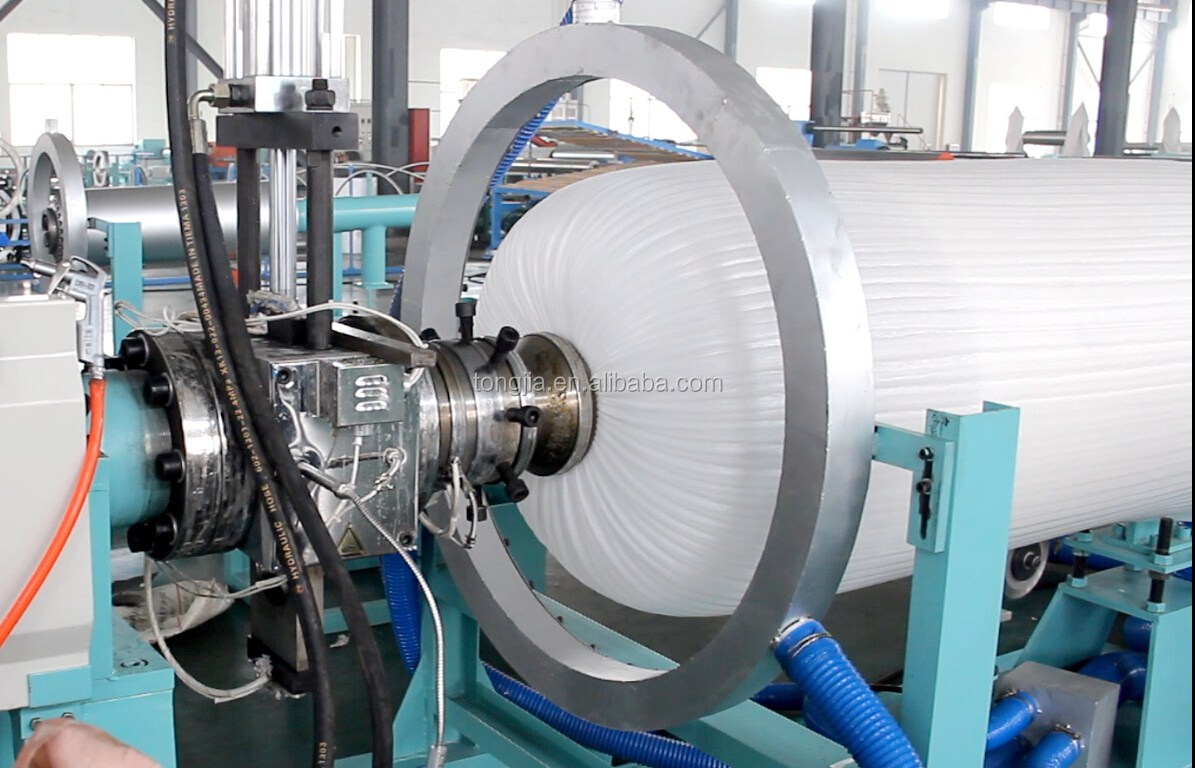

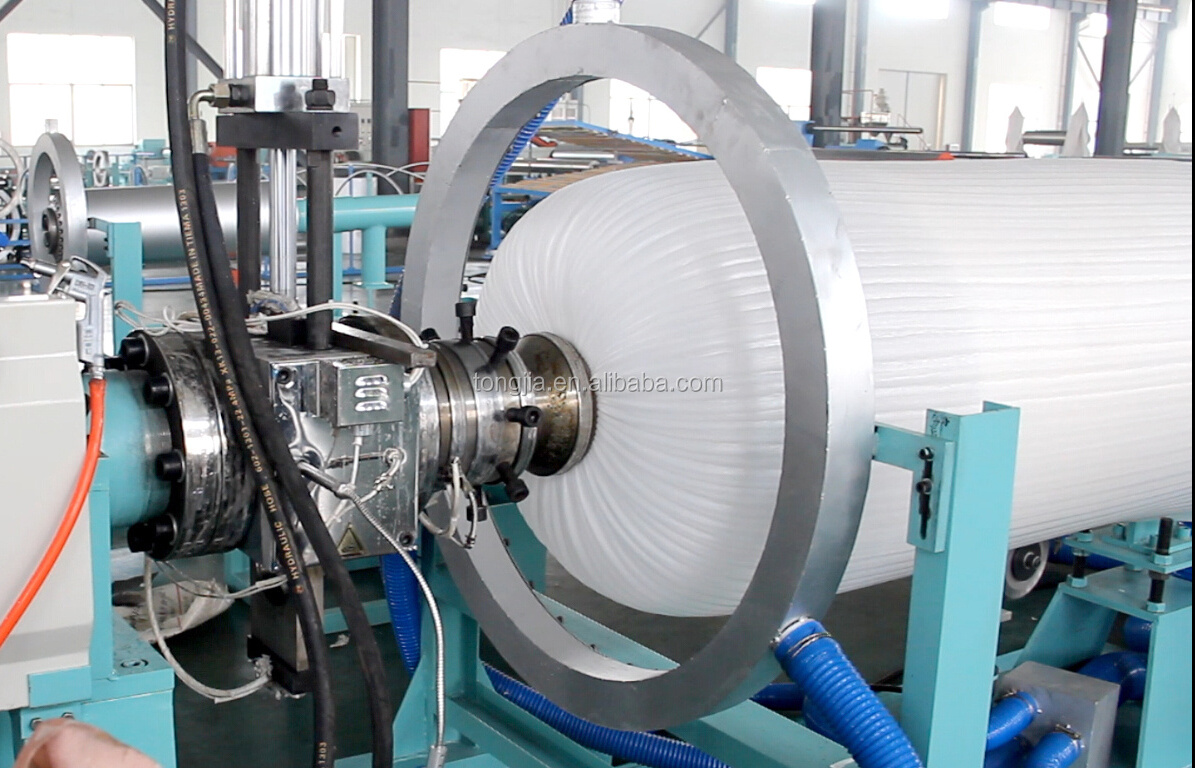

Details Images

Recommend Products

Product packaging

Standard export packaging

1. Apply anti-rust oil to the equipmenteasy rustypart and carry out anti-rust treatment.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-movepart of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

5. Use New Zealand imported bluish pine wood or American Douglas fir wood as the bottom support, 12mm multi-layer plywood for side panels, all wood fumigated. We cooperated withexperienced and professionalexported wooden packaging manufacturing enterprises to make final package.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-movepart of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

5. Use New Zealand imported bluish pine wood or American Douglas fir wood as the bottom support, 12mm multi-layer plywood for side panels, all wood fumigated. We cooperated withexperienced and professionalexported wooden packaging manufacturing enterprises to make final package.

Hot Searches