- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FKM Rubber O-Ring Seals

-

Material:

-

Fluororubber/Silicone/VMQ/NBR/Nitrile/FKM/EPDM/PU/PTFE

-

O-Ring Sample:

-

Free of Charge

-

Feature:

-

Resistant to heat, fatigue, aging,UV and friction

-

Certificate:

-

RoHS, ISO 9001:2005,REACH

-

Working Temperature:

-

-50℃~+300℃

-

Keyword:

-

Rubber Seal O Ring

-

Hardness:

-

30 Shore A - 95 Shore A

-

Dimension:

-

AS568 or Custom O Ring Seal

-

Forming Method:

-

Compression Molding O-ring Seal

-

OEM / ODM:

-

Available

Quick Details

-

Size:

-

Standard and Custom O-Ring Seal

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

SWKS OR CUSTOM LOGO

-

Model Number:

-

FKM Rubber O-Ring Seals

-

Material:

-

Fluororubber/Silicone/VMQ/NBR/Nitrile/FKM/EPDM/PU/PTFE

-

O-Ring Sample:

-

Free of Charge

-

Feature:

-

Resistant to heat, fatigue, aging,UV and friction

-

Certificate:

-

RoHS, ISO 9001:2005,REACH

-

Working Temperature:

-

-50℃~+300℃

-

Keyword:

-

Rubber Seal O Ring

-

Hardness:

-

30 Shore A - 95 Shore A

-

Dimension:

-

AS568 or Custom O Ring Seal

-

Forming Method:

-

Compression Molding O-ring Seal

-

OEM / ODM:

-

Available

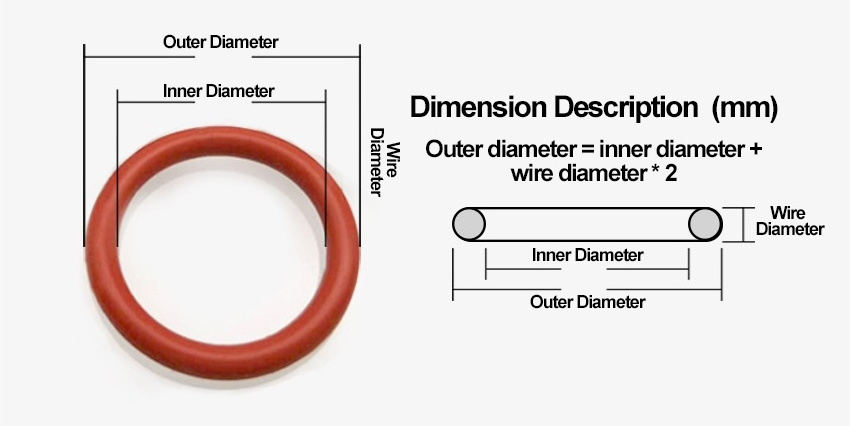

An o-ring is a simple and versatile ring-shaped packing or sealing device with a circular cross section (from which the “O” in its name is derived). The purpose of using O-ring seals is to prevent leakage and loss of liquids or gases. They simplicity,convenience, and small installation space. As long as the groove design and material selection are correct, and the operating conditions are within the temperature range of the rubber material, the seal can have a long-term sealing effect in the static or dynamic seal.

Rubber o rings SWKS can supply

a) Metric o rings standard or non-standard sizes

b) AS568 o ring standard sizes

c) Japanese JIS O-Rings

d) British BS O-Ring

e) Custom o rings,any color or durometer hardness,specialty bagging, labeling, marking or inspection.

|

Product Name

|

Custom 60 - 95 Duromter FKM O-Rings Seals, Fluororubber Oring, Rubber O Rings

|

|

|

|

|||

|

Dimensions

|

AS 568, BS 4518 standard sizes and various customized sizes.

|

|

|

|

|||

|

Material

|

HNBR, NBR, FKM, Silicone,VMQ, EPDM,Nylon,Polyurethane,Nitrile and so on.

|

|

|

|

|||

|

Tolerance Standard

|

ISO2768-M or ISO3302-1:2014 CLASS M2

|

|

|

|

|||

|

Color

|

Blue, Green, Red, Yellow or other colour as customer need

|

|

|

|

|||

|

Brand

|

SWKS, or custom's brand

|

|

|

|

|||

|

Hardnesss

|

30 Shore A to 95 Shore A

|

|

|

|

|||

|

Feature & Advantage

|

Resistance to oil,chemical corrosion, high temperature,deformation and wear.

|

|

|

|

|||

|

Price Tip

|

1. The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order qty, package request, etc.

2. Our price is not the lowest one, but compared with the same quality level product, ours is the best one.

|

|

|

|

|||

FKM o-ring(Fluorocarbon)

Temperature Range: -20℃ to 250℃

Durometer:50 - 90 Shore A

Color:Black/Brown/Green other color can customize

Application:Oil resistance, chemical resistance, wear resistance, acid and alkali resistant, high temperature resistance

Silicone Rubber o-ring (VMQ)

Temperature Range: -70℃ to 300℃

Hardness: 25 - 90 Shore A

Color:Red/Transparent(Clear)/White,etc.

Advantage:Heat resistance, coldresistance,lubrication oil resistance,waterresistance.

NBR O-ring(Nitrile rubber oring)

Temperature Range: -40℃ to 150℃

Hardness: 50-90 Shore A

Color:Black/Orange/Green other color can customize

Use:Oil and Chemical resistance, Wear resistance,Acid and alkali resistant,High temperature resistance.

HNBR O-ring(Hydrogenated Nitrile Butadiene)

Temperature Range: -40℃ to 180℃

Hardness: 50-90 Shore A

Color: Black,Green other color can customize

Advantage:Excellent ozone resistance, Heat resistance, Mechanical strength,Ozone resistance batter than NBR

CR O-ring (Neoprene Rubber Oring)

Temperature Range:-40℃ to 120℃

Hardness:60-90 Shore A

Color:Black,other color can customize

Advantage:Excellent Mechanical strengthand Fatigue resistance.

EPDM o-ring(Ethylene Propylene Rubber)

Temperature Range:-50

℃

to 150

℃

Hardness:40-90 Shore A

Color:Black,White other color can customize Advantage:Excellent Ozone resistance, Heat resistance, Steam resistance,Cold resistance.

Product size,materials, quantity, price,payment terms,shipping terms and others can be negotiated.We can produce any size and shape according to your drawing. Give us idea, we make it done in reality.

Tianjin SWKS is a global manufacturer for custom rubber parts and components. Our capabilities includes mold making, injection molding, compression molding,parts assembly. Our products material range from plastic, rubber to metal, covering industries such as automotive, agriculture, food&beverage, consumer electronics, medical equipment, etc.

We strictly follow the needs of each customer: quality, specification, size and quantity to arrange processing and production. When you choose SWKS, you get an expert partner through the entire production cycle, taking your product from concept to reality.

We have the trade department,engineer deparment, production deparment and after-sales service department. There are more than 60 QC staff to control the quality.Every product will be 100% checked before shipping.If the order goods have problem, we will solve it within 24 hours, and we will replace the product for you without any cost.

TESTING EQUIPMENT

Many rubber material for you choose

Nitrile ( Buna-N) (NBR) General industrial use material for oil, grease and solvent resistance.

Silicone Excellent material for resistance to aging, heat, sunlight, many oils, and chemicals.

Fluroelastomer (FKM) Excellent resistance to oils, fuels and solvents at higher temperature ranges.

EPDM Excellent resistance to heat aging, ozone, acids, and alkalines.

Neoprene General industrial material used with non-aromatic petroleum oils and greases.

Choose materials according to the usage, please find rubber properties chart bellow.

Any questions please contact

Suzy Wei

to get more details

SWKS produces products following IOS9001:2005 strictly,the quality conforms to European Union RoHs standards.We have implemented quality and management systems that measure up to the toughest standards. We test every batch of material to verify that its key physical properties are conforming. Every molding press is computer controlled to ensure consistency and to optimize productivity. Trust you'll like our quality and price.

Cooperating customer from more than 30 countries. Received unanimous praise.

If you want custom service,please kindly send us the detail information(material,finish,size,etc).It would be better if you can send us CAD/3D drawing or picture for our understanding or you can send us samples,we will manufacture the products 100% according to your samples.

Hot Searches