Boron carbide powder from China B4C F400 F500 F600 F800 microns

-

Transport Package:

-

25kgs per bucket

-

Specification:

-

F400-F800

-

Trademark:

-

HAIXU ABRASIVES

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

China

-

Natural Abrasive Type:

-

Other

-

Artificial Abrasive Type:

-

Other

-

Application:

-

Machinery Metal Parts

-

Function:

-

Surface Finish

-

Source:

-

Artificial Abrasives

-

Particle Size:

-

Abrasive Ultrafine

-

Hardness:

-

Conventional Abrasive 9.2-9.3

-

Mohs Hardness:

-

9.2-9.3

-

Payment:

-

L/C T/T Paypal

-

Export Port:

-

Tianjin

-

Output:

-

200 Tons per year

-

Model NO:

-

F400-F800

Quick Details

-

Mohs Hardness:

-

9.2-9.3

Products Descripition

Boron carbide powder from China B4C F400 F500 F600 F800 microns

Boron carbide or B4C is an excellent wear-resistant and high-temperature resistant synthetic material. Boron carbide is produced by high-temperature smelting of boric acid and carbides into blocks, followed by crushing and sorting. It has high hardness, moderate grinding force, low specific gravity, and strong neutron shielding ability against radiation substances. Therefore, it can not only be used for wear-resistant materials and grinding media, but also as one of the main raw materials for boron carbide wear-resistant ceramics and nuclear industry protective materials.

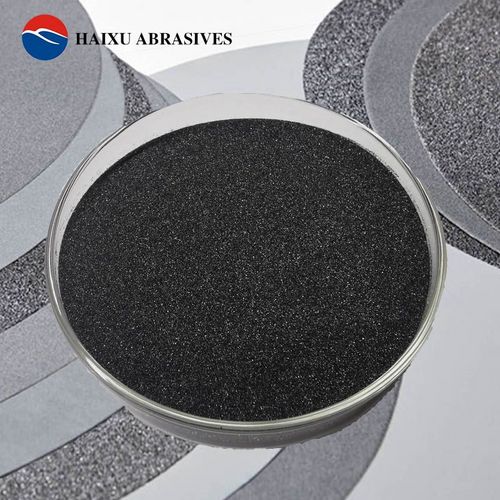

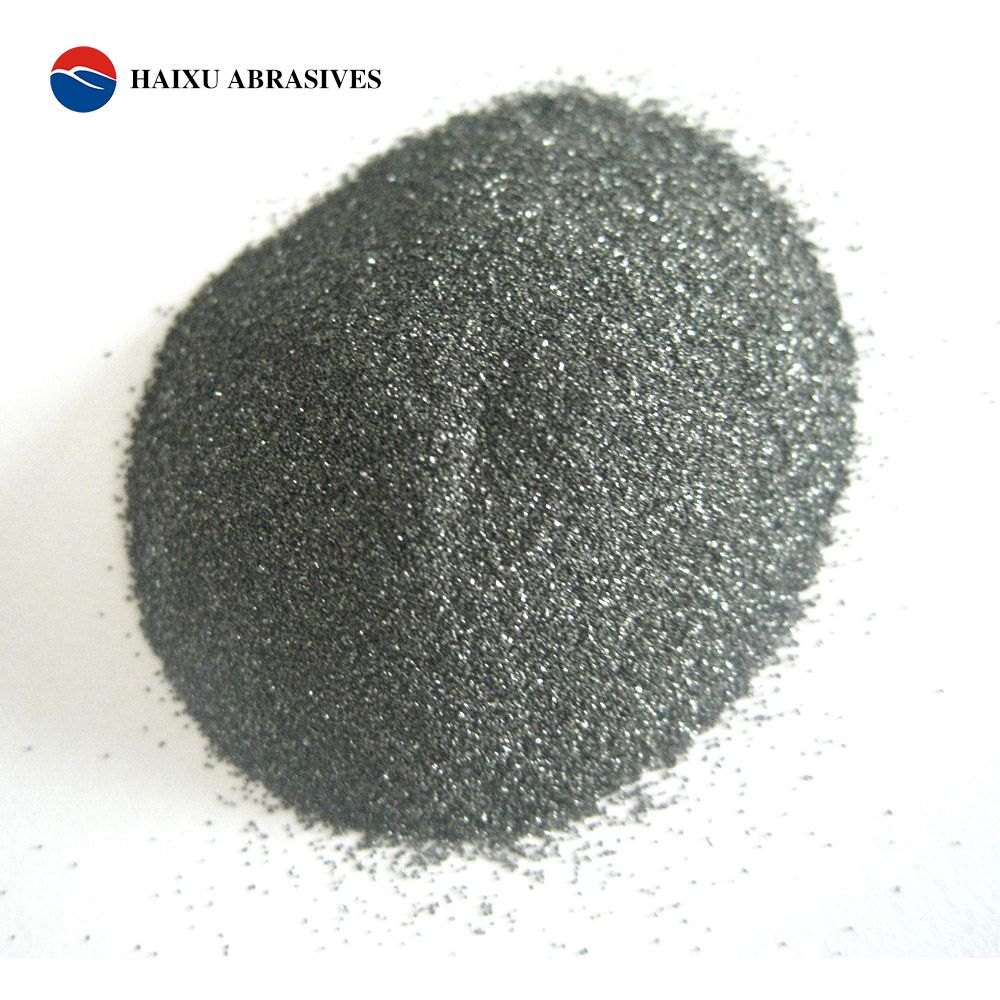

Product Image

Advantage Introduction

Boron carbide powder from China B4C F400 F500 F600 F800 microns properties

1. High strength and good fracture toughness.

2. Low density and low specific gravity.

3. Excellent fire resistance performance.

4. High temperature hardness and good wear resistance.

5. Chemical stability, able to withstand the erosion of acidic and alkaline substances.

6. Strong thermal conductivity.

Product Index

Technical index:

| Appearance | Black grain or powder |

| Molecular Weight)(g/mol.) | 55.25515 |

| Specific Heat(cal-mol-c) | 12.5 |

| Elastic modulus | 450-470 Gpa |

| Knoop hardness | 2750 kg/mm2 |

| Mohs hardness | 9.3 |

| Micro Hardness | 4950 KGF/mm2 |

| Density | 2.52g/cm |

| Melting point | 2350℃(2623.15K) |

| Boiling point | >3500℃(>3773.15K) |

| conductivity | 140 s/cm |

| thermal conductivity | 30 - 42 W/M·K |

| thermal neutron absorption cross section | 600 barn |

| Solubility in water | Insoluble |

| Crystal structure | Rhombohedral |

| CAS NO. | 12069-32-8 |

Chemical composition:

| Chemical | Standard Value | Typical Value |

| Total Boron (BT) | 75-80 % | 78.18 % |

| Free Boron(BF) | ≤0.5 % | 0.1 % |

| Boron Oxide(B2O3) | ≤1.0 % | 0.09 % |

| Total Carbon (CT) | 17-21.5% | 19.71 % |

| Free Carbon (CF) | ≤2.0 % | 1.24 % |

| Iron Oxide(Fe2O3) | ≤0.5 % | 0.16 % |

| Boron Carbide(B4C) | 93-97 % | 96.55 % |

| BT+CT | 93-98% | 97.89 % |

Specification

Available sizes:

F-macrogrit F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220

F-microgrit F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000

Fine powder:-100#,-200#,-325#,60-150#,25um-0,10um-0,3um-0

1. F-macrogrit

| Grit Size | Mean diameter in um |

| F40 | 438 |

| F46 | 370 |

| F54 | 310 |

| F60 | 260 |

| F70 | 218 |

| F80 | 185 |

| F90 | 154 |

| F100 | 129 |

| F120 | 109 |

| F150 | 82 |

| F180 | 69 |

| F220 | 58 |

2. F-microgrit

| Grit Size | Mean grain size ds50-value in μm |

| F 230 | 53.0 ± 3 |

| F 240 | 44.5 ± 2 |

| F 280 | 36.5 ± 1.5 |

| F 320 | 29.2 ± 1.5 |

| F 360 | 22.8 ± 1.5 |

| F 400 | 17.3 ± 1 |

| F 500 | 12.8 ± 1 |

| F 600 | 9.3 ± 1 |

| F 800 | 6.5 ± 1 |

| F 1000 | 4.5 ± 0.8 |

| F 1200 | 3.0 ± 0.5 |

| F 1500 | 2.0 ± 0.4 |

| F 2000 | 1.2 ± 0.3 |

3. Fine powder:

| Specification | Particle size |

| 100mesh | +150 um ≤10% |

| 200mesh | +75 um≤10% |

| 325mesh | +45 um≤10% |

| 25um-0 | +25 um≤10% |

| 10um-0 | +10 um≤10% |

| 3um-0 | +3 um≤10% |

*Other customized sizes are available upon request.

Usage

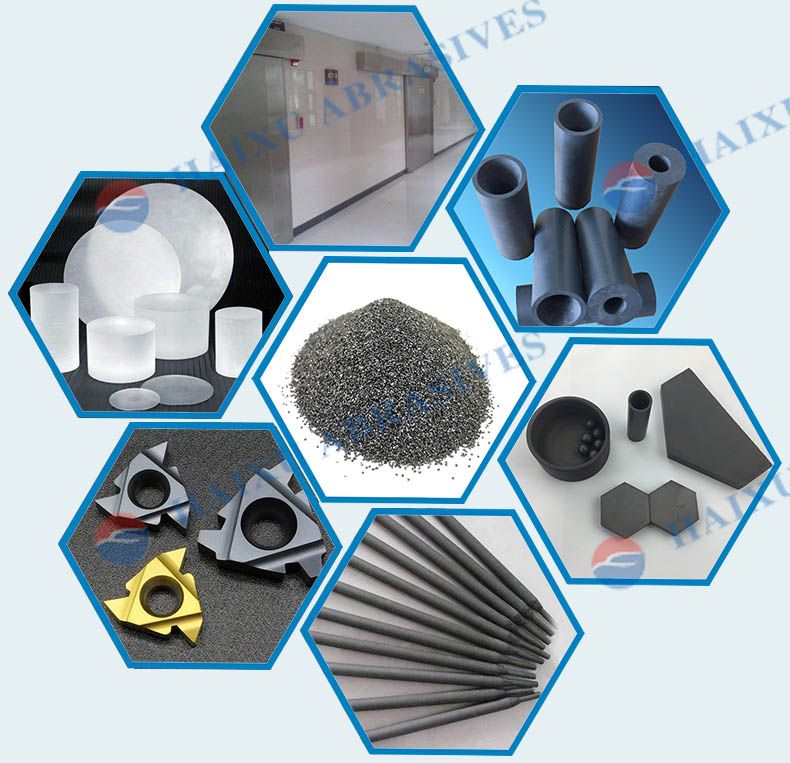

Product Usage:

1. Grinding and polishing of sapphire crystals, optical crystals, window panels, gemstones, and other materials.

2.SiC-B4C composite wear-resistant ceramics. For example, ceramic nozzles, ceramic plates, ceramic sheets, armor, etc.

3. Wear resistant and impact resistant coating.

4. Neutron absorption shielding materials for the nuclear industry. For example, pouring concrete for nuclear reactors, neutron absorbing refractory bricks, etc.

5. Radiation resistant building materials in the field of medical equipment such as polyethylene Neutron Shielding.

6. Hard alloy powder with wear-resistant materials added.

7. Special wear-resistant electrode core.

8. Wear resistant materials such as brake pads.

9. Wear resistant and impact resistant additives for alloy powder and metallurgical materials.

Packaging&Shipping

Package: