- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

300kw

-

Weight:

-

50T

-

Dimension(L*W*H):

-

22.4*10*26m

-

Warranty:

-

1 year

-

Color:

-

Green

-

Name:

-

100 ton per day industrial corn flour mill machine

-

Type:

-

Automatic

-

Raw material:

-

Wheat Maize Corn

-

Application:

-

Institutes

-

Final products:

-

maize grits, maize flour

-

Capacity:

-

100T/D

-

place of origin:

-

Henan, China

-

Product name:

-

industrial corn mill

-

Certification:

-

ISO, CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TAIXING, TAIXING

-

Production Capacity:

-

100TPD

-

Voltage:

-

380V

-

Power:

-

300kw

-

Weight:

-

50T

-

Dimension(L*W*H):

-

22.4*10*26m

-

Warranty:

-

1 year

-

Color:

-

Green

-

Name:

-

100 ton per day industrial corn flour mill machine

-

Type:

-

Automatic

-

Raw material:

-

Wheat Maize Corn

-

Application:

-

Institutes

-

Final products:

-

maize grits, maize flour

-

Capacity:

-

100T/D

-

place of origin:

-

Henan, China

-

Product name:

-

industrial corn mill

-

Certification:

-

ISO, CE

Product Description

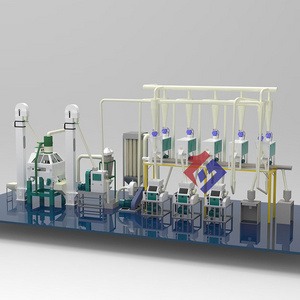

100 ton per day industrial corn mill machine/maize milling machine:

The 100T/Day maize flour Production Line Corn Flour Mill grain Crusher cereal grinding machine consisits of corn seeds cleaning,peeling, degerming, crushing, gentle milling, sifting and flour bagging. Using dry peeling and degerming technology, it can produce different sizes of corn gritd and flour simultaneously . Corn grits size can be customized as different customers' need in order to meet various of needs such as brewery, snack food, glucose, sugarhouse.

Features of 100 ton per day industrial corn mill machine/maize milling machine:

1. The automatic pneumatic wheat flour milling machine adopts the whole pneumatic control, has the advantages of highsensible action, neat and tidy, no polution to the environment; It can be operated both in separately and centralizedly.

2. The feeding system adopts double and tilting grinding rollers, together with the drive to achieve stablity and reliablity; The automatic pneumatic wheat flour milling machine also has a feeding servo system that makes the feeding equal.

3. The automatic pneumatic wheat flour milling machine has one sensible impulser that can control the quantity change of materials to achieve self-control feeding together with the servo system.

4. The automatic pneumatic wheat flour milling machine has a shock pad that can control exclude the vibration when flour grinding.

5. The automatic pneumatic wheat flour milling machine has one set of special roller handling tools to make the process safe, convenient, time-saving, and labour-saving.

6. The automatic pneumatic wheat flour milling machine is with the advantages of novel structure, discharging equal, less noise, good stability, easy operation, convenient maintenance, etc.

2. The feeding system adopts double and tilting grinding rollers, together with the drive to achieve stablity and reliablity; The automatic pneumatic wheat flour milling machine also has a feeding servo system that makes the feeding equal.

3. The automatic pneumatic wheat flour milling machine has one sensible impulser that can control the quantity change of materials to achieve self-control feeding together with the servo system.

4. The automatic pneumatic wheat flour milling machine has a shock pad that can control exclude the vibration when flour grinding.

5. The automatic pneumatic wheat flour milling machine has one set of special roller handling tools to make the process safe, convenient, time-saving, and labour-saving.

6. The automatic pneumatic wheat flour milling machine is with the advantages of novel structure, discharging equal, less noise, good stability, easy operation, convenient maintenance, etc.

Specification

|

Capacity

|

Power(kW)

|

Workshop area (M)

|

Final product

|

|

10T/24h

|

40

|

8.4x3.4x3.8

|

Corn flour

|

|

30T/24h

|

100

|

15x7x4.5

|

Corn flour,corn girts

|

|

50T/24h

|

160--200

|

26.4x7x7.5

|

Corn flour,corn girts

|

|

100T/24h

|

250--300

|

22.4×10×26

|

Corn flour,corn girts

|

|

200T/24h

|

530

|

35×11×26

|

Corn flour,corn girts

|

Packaging & Shipping

Service:

1.Design according to your special requirement.

2.Free repair within 1 year.

3.Engineer could work to your country

4.we are responsible for installation, test running and trainning local workers for you.

Hot Searches