- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

MAGE

-

Year:

-

2022

-

Voltage:

-

220V--600V

-

Dimension(L*W*H):

-

1450*1000*280

-

Weight (T):

-

5 T

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

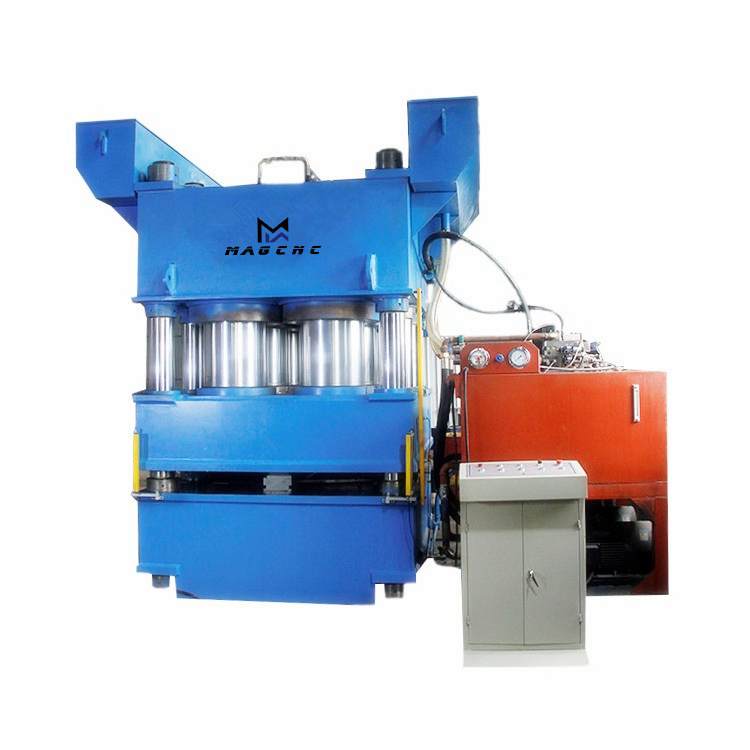

Four Column Hydraulic Press Machine

-

Color:

-

customizable

-

Motor(options,servo motor):

-

Germany Siemens

-

Major electrical components:

-

Siemens of Omron (Optional)

-

Displacement sensor:

-

Giffron, Italy

-

Main oil cylinder:

-

TMINT (TENG MING)

-

Main cylinder seal ring:

-

Japan

-

Keyword:

-

Hydryalic Press

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

300, 500

-

Return Force (kN):

-

400 kN

-

Place of Origin:

-

China

-

Brand Name:

-

MAGE

-

Year:

-

2022

-

Voltage:

-

220V--600V

-

Dimension(L*W*H):

-

1450*1000*280

-

Weight (T):

-

5 T

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

Four Column Hydraulic Press Machine

-

Color:

-

customizable

-

Motor(options,servo motor):

-

Germany Siemens

-

Major electrical components:

-

Siemens of Omron (Optional)

-

Displacement sensor:

-

Giffron, Italy

-

Main oil cylinder:

-

TMINT (TENG MING)

-

Main cylinder seal ring:

-

Japan

-

Keyword:

-

Hydryalic Press

Product Description

Hydraulic Press

1.low noise, noise can be controlled at about 60 decibels.

2.Working position, speed and pressure can be adjusted steplessly.

3.High efficiency and energy saving, energy consumption is 30% -50% less than ordinary motors.

4.Quick response, high pressure and position repeatability.

5.High efficiency, multiple protections inside, extremely low failure rate.

6.12 hours of continuous work does not require cooling oil temperature.

7.European CE standard hydraulic system and electrical safety IP54 level.

1.low noise, noise can be controlled at about 60 decibels.

2.Working position, speed and pressure can be adjusted steplessly.

3.High efficiency and energy saving, energy consumption is 30% -50% less than ordinary motors.

4.Quick response, high pressure and position repeatability.

5.High efficiency, multiple protections inside, extremely low failure rate.

6.12 hours of continuous work does not require cooling oil temperature.

7.European CE standard hydraulic system and electrical safety IP54 level.

1.Quality;

1.1. Appearance: The layout is reasonable (designed by China Design Institute), and the paint adopts export-specific paint througha triple process.

1.2. Weight: The weight of the machine of the same model is much heavier than that of other

1.1. Appearance: The layout is reasonable (designed by China Design Institute), and the paint adopts export-specific paint througha triple process.

1.2. Weight: The weight of the machine of the same model is much heavier than that of other

manufacturers, and the service life is longer.

1.3. Material: use Jinan Iron and Steel Q235 plate and special plate for hydraulic press

2. Process:

2.1. Frame: The tempering kiln is adopted, the structure is more tight, and the load is not deformed.

2.2. Column: using vibration to eliminate internal stress (using forging)

2.3. Hydraulic oil cooling: 1 water cooling 2 air cooling 3 industrial air conditioning refrigeration (optional)

2.4. The noise is low, the national standard is 70 to 100 decibels, and the machine is tested to be 70 decibels

3. Core Competence

3.1. Excellent material, exquisite workmanship, high configuration, simple operation, strong practicability, low maintenance cost and high safety.

3.2. According to customer needs: adopt a fully automatic production line or install a fully automatic production line later.

1.3. Material: use Jinan Iron and Steel Q235 plate and special plate for hydraulic press

2. Process:

2.1. Frame: The tempering kiln is adopted, the structure is more tight, and the load is not deformed.

2.2. Column: using vibration to eliminate internal stress (using forging)

2.3. Hydraulic oil cooling: 1 water cooling 2 air cooling 3 industrial air conditioning refrigeration (optional)

2.4. The noise is low, the national standard is 70 to 100 decibels, and the machine is tested to be 70 decibels

3. Core Competence

3.1. Excellent material, exquisite workmanship, high configuration, simple operation, strong practicability, low maintenance cost and high safety.

3.2. According to customer needs: adopt a fully automatic production line or install a fully automatic production line later.

Specifications

|

Project

|

|

315T

|

400T

|

500T

|

630T

|

800T

|

1000T

|

1250T

|

2000T

|

|

|

Normal force (kn)

|

|

3150

|

4000

|

5000

|

6300

|

8000

|

10000

|

12500

|

20000

|

|

|

Maximum working pressure of liquid

|

|

28

|

26

|

28

|

28

|

25

|

25

|

25

|

25

|

|

|

Oil cylinder maximum trip

|

|

600

|

700

|

900

|

900

|

900

|

900

|

900

|

900

|

|

|

Maximum opening (mm)

|

|

1100

|

1200

|

1500

|

1500

|

1500

|

1500

|

1600

|

1600

|

|

|

Table effective area (mm)

|

right and left

|

1260

|

1400

|

1400

|

1600

|

1500

|

1500

|

1700

|

2000

|

|

|

|

forward and backward

|

1160

|

1250

|

1400

|

1600

|

1500

|

1500

|

1600

|

2000

|

|

|

Fast forward speed (mm/s)

|

|

130

|

130

|

130

|

130

|

100

|

80

|

80

|

80

|

|

|

Feeding speed (mm/s)

|

|

8-13

|

8-32.5

|

12-26

|

12-26

|

5-12

|

6-10

|

6-10

|

6-10

|

|

|

Return speed (mm/s)

|

|

60

|

70

|

70

|

70

|

60

|

50

|

45

|

40

|

|

|

Motor power (kw)

|

|

15

|

18.5

|

15*2

|

18.5*2

|

37*2

|

37*2

|

37*2

|

37*2

|

|

|

Bottom cylinder pressure (kn)

|

|

630

|

1000

|

1000

|

1000

|

1250

|

1250

|

2000

|

2500

|

|

|

Bottom stroke (mm)

|

|

300

|

300

|

300

|

300

|

350

|

350

|

450

|

450

|

|

Product details

Grating protection standard configuration

Rexroth valve set

PLC control system optional

Siemens electric standard configuration

Special power tank

Siemens servo motor optional

Factory Workshop

Certificate showing

Customer and Packaging

FQA

Q:Are you a manufacturer or a trader?

A: Our company is A large manufacturing enterprise with the headquarters in Anhui and three production bases.

A: Our company is A large manufacturing enterprise with the headquarters in Anhui and three production bases.

Q:What if we can't

operate your machine?

1. Provide overseas engineer services

2. Support online video operation teaching

3. Provide installation and operation teaching videos.

Q: How about your machine quality?

1. The main parts of the machine adopt international brands

2. Adopt advanced welding technology, the weld is firm and smooth.

3. The machine frame adopts high strength steel, and adopts advanced technology finite element analysis and tempering

kilntreatment. Long service life of the structure.

Q:What's your delivery time?

A: Generally 25 to 35 Working days, if urgently order, pls contact our sales in advance.

Q:Why do you choose our company?

1. Rigorous Have a serious and responsible attitude towards everything, keep improving

2. Provide a full range of after-sales service, use to buy the machine without worries.

operate your machine?

1. Provide overseas engineer services

2. Support online video operation teaching

3. Provide installation and operation teaching videos.

Q: How about your machine quality?

1. The main parts of the machine adopt international brands

2. Adopt advanced welding technology, the weld is firm and smooth.

3. The machine frame adopts high strength steel, and adopts advanced technology finite element analysis and tempering

kilntreatment. Long service life of the structure.

Q:What's your delivery time?

A: Generally 25 to 35 Working days, if urgently order, pls contact our sales in advance.

Q:Why do you choose our company?

1. Rigorous Have a serious and responsible attitude towards everything, keep improving

2. Provide a full range of after-sales service, use to buy the machine without worries.

Hot Searches