The

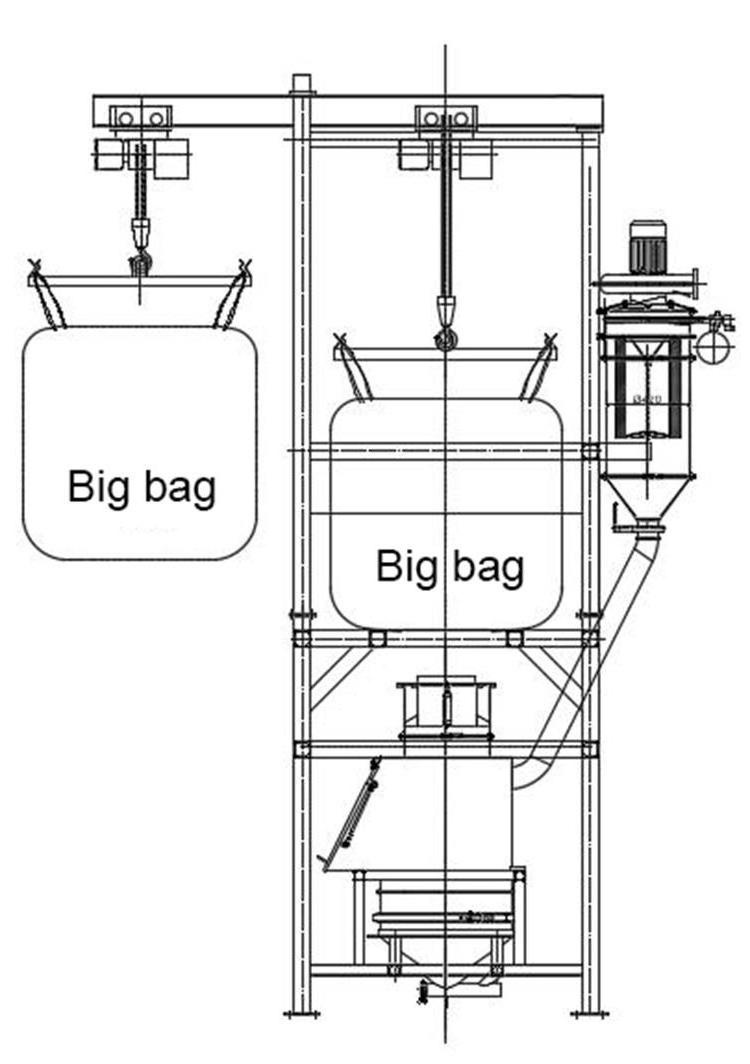

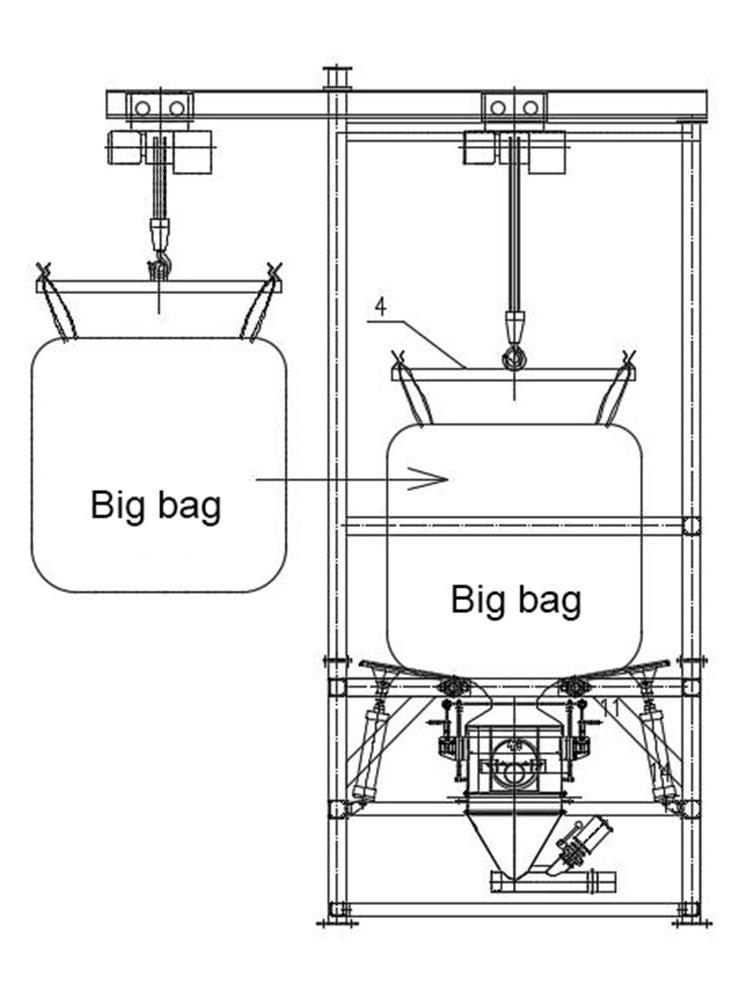

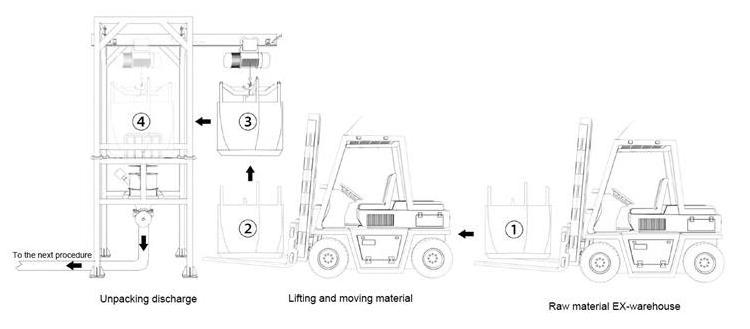

Food Industry Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

lifts the bulk bag to the top of the feeding inlet of the equipment through the electric hoist. The

inner bag of the big bag is manually fixed at the clamping mouth of the equipment, and the big bag is clamped and sealed by the

bag holder to prevent dust overflow. The bag is then manually opened and unloaded, aided by devices such as beaters and vibrators,

to facilitate complete unloading of the material inside the bulk bag. The unloaded material can be directly fed into the equipment

of the next process or used for unpacking and feeding in pneumatic conveying or screw conveying systems.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KARP

-

Product Name:

-

Food Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

-

Application:

-

Bag Unloading

-

Material:

-

Stainless steel 304/316/Mild steel

-

Advantage:

-

Dust free

-

Equipment height:

-

3000mm-5000mm

-

Blanking butterfly valve caliber:

-

150mm-200mm

-

Bag caliber:

-

300mm

-

Capacity:

-

0.1-6ton/h

-

Air consumption:

-

0-0.6L/min

-

Vacuum flow:

-

0-90L/min

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

1000

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KARP

-

Product Name:

-

Food Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

-

Application:

-

Bag Unloading

-

Material:

-

Stainless steel 304/316/Mild steel

-

Advantage:

-

Dust free

-

Equipment height:

-

3000mm-5000mm

-

Blanking butterfly valve caliber:

-

150mm-200mm

-

Bag caliber:

-

300mm

-

Capacity:

-

0.1-6ton/h

-

Air consumption:

-

0-0.6L/min

-

Vacuum flow:

-

0-90L/min

Food Industry Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

Product Description

Brief description:

Food Industry Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

is a specialized equipment designed for feeding and unpacking large packaging bags, specifically addressing issues such as dust overflow and excessive dust emissions during the feeding process. It is primarily used for unpacking and unloading granular and powdered materials contained in bulk bags, including food ingredients, chemical raw materials,

additive, lithium battery industry

, rubber and plastic industries, energy batteries, paint industry, and the coatings industry.

Two models are available:

1. D-TL-1

Suitable for big bag (larger than 1 ton) unloading

Working principle:

2. D-TL-2

Suitable for big bags and small bags unloading

Working principle:

D-TL-2 series big bag handling and discharge system added the feeding function of small bag packaging materials based on D-TL-1 Big bag unloading station. When unpacking big bags, it is equivalent to D-TL-1. When unpacking small bags, the dust collection fan of the dust collection box can avoid the material dust flying everywhere. When the material is unpacked and poured into the next process, it only needs to be manually unpacked directly into the system. When the material passes through the vibrating screen, the big size material and foreign matter can be intercepted, so as to ensure the removal of particles which are unqualified.

Main features:

1. Meet GMP certification and food hygiene certification standards. Applicable field: food, chemical, additive, lithium battery industry and other

industries.

2. According to different materials it is made of mild steel, stainless steel 304, stainless steel 316, Ti steel, etc.

3. Simple structure, easy operation, enclosed and no dust flying. Improve the working environment, sealing well, no leakage, less

residue.

4. According to the variety of packaging

specifications, bag filling rate and material characteristics, etc., it can be designed according to customer requirements.

5. It can work with vacuum feeder, screw conveyor, vibrating feeder and other conveying machines to transfer the material into next production equipment, such as mixer, silo, reactor, packing machine, vibrating screen, etc.

Specification

|

Basic parameters for Food Industry Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

|

|

|

|

|||

|

Equipment height

|

[3000mm, 5000mm]

|

Air consumption

|

(0L/min, 0.6L/min)

|

|||

|

Bag caliber

|

300mm

|

Vacuum flow

|

(0L/min, 90L/min)

|

|||

|

Air source pressure

|

6bar

|

Vacuum pressure

|

(-92.5kpa, 0kpa)

|

|||

|

Equipment weight

|

[1000kg, 5000kg]

|

Throughput (capacity)

|

(0.1T/h, бТ/h)

|

|||

|

Blanking butterfly valve caliber

|

[150mm, 200mm]

|

Item restrictions

|

Sticky material

|

|||

|

Applicable Material Properties

|

|

|

|

|||

|

Material Type

|

Powder

|

Granule

|

Liquid

|

|||

|

Material temperature

|

[-10℃, 70℃)

|

[-10℃, 70℃)

|

/

|

|||

|

Material Humidity

|

(0%RH, 20%RH)

|

(0%RH, 20%RH)

|

/

|

|||

|

Material particle size

|

(0.2um, 10mm)

|

(0.2um, 10mm)

|

/

|

|||

Product Show

Unloading hopper

Dust remover

Big Bag Unloading Station made of contacting material SS304

Bag unloading station with small bag dumping station, suitable for unloading big and small bags

Carbon steel full enclosed big bag unloader

FIBC Discharger works with vacuum conveyor

Big bag unloading station works with screw conveyor

Application

Food Industry Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

is

mainly used for unpacking and unloading big bags of granular and powdery materials in food industry, chemical industry

, additive, lithium battery industry, rubber and plastic industry, energy batteries industry, paint industry, etc.

1. All dry, well-flowing materials, such as fertilizers, animal feed, flakes, cereals, sugar, metallurgical concentrates, wood

pellets, floor screeds, cement, circulating products, soil, peat, etc.

2. Plastic resins and food additives and other dry powder and granular materials.

3. Flavors and fragrances, monosodium glutamate, adsorbents, catalysts, graphite, rouge, blush, polyethylene, polypropylene,

polyoxyethylene, fertilizers, feed, premixes, additives, laundry powder, salt, monosodium glutamate, chicken

essence, sugar, seeds and other materials.

4. Bulk bag packaging materials with poor fluidity, easy moisture absorption and caking.

Hot-selling product

Packing & Delivery

Packing for

Food Industry Jumbo Bag Unloading Machine Bulk Ton Big Bag Unloader Station

.

Outside package: standard export wood box.

Inner package: stretch film for machine, accessories in carton.

Optional shipping type: Support Sea freight

Hot Searches