- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Stainless steel Mixing Liquid Eductors sparger nozzle

-

Thread size:

-

1/4',3/8",1/2",3/4",1",1-1-2".1.5"

-

Thread type:

-

Male thread

-

Material:

-

Plasatic PE PVDF PP, stainless steel .304SS.316SS

-

Operate pressure:

-

0.5-45psi

-

Operating temperature:

-

0-85℃

-

Application:

-

Spare parts washing and cleaning

-

Sample:

-

available

-

After Warranty Service:

-

Video technical support

Quick Details

-

Weight (KG):

-

0.098

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Xinhou

-

Product name:

-

Stainless steel Mixing Liquid Eductors sparger nozzle

-

Thread size:

-

1/4',3/8",1/2",3/4",1",1-1-2".1.5"

-

Thread type:

-

Male thread

-

Material:

-

Plasatic PE PVDF PP, stainless steel .304SS.316SS

-

Operate pressure:

-

0.5-45psi

-

Operating temperature:

-

0-85℃

-

Application:

-

Spare parts washing and cleaning

-

Sample:

-

available

-

After Warranty Service:

-

Video technical support

|

Name

|

Plastic PP PVDF Stainless Steel 304 316 Mixing Liquid sparger tank eductors jet spray nozzle

|

|

|

||

|

Thread size

|

1",1/4',3/8",3/4",1/2",1-1/2".1.5"

|

|

|

||

|

Material

|

Plastic(PP,PE,PVDF);Stainless steel(304SS;316SS)

|

|

|

||

|

Application

|

Automobile,Coating│Painting;Phosphatic Tank

Paint Stirring Tank C.I.P Tanks│Cooling Tower;Anodizing Tank Mixing;Ionic-Exchange Facility |

|

|

||

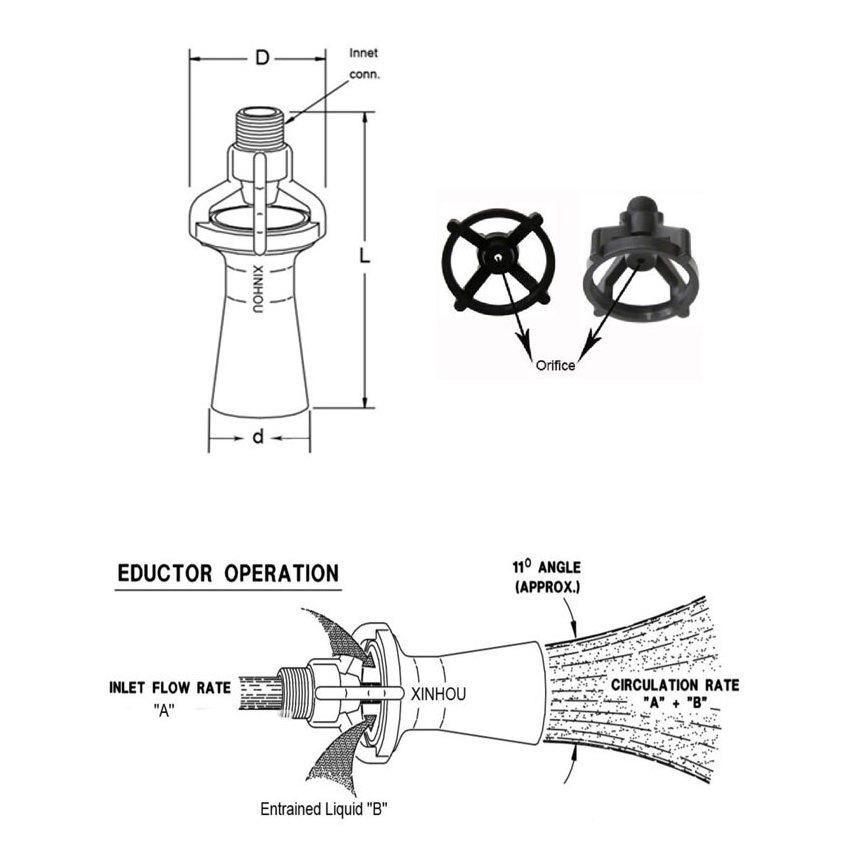

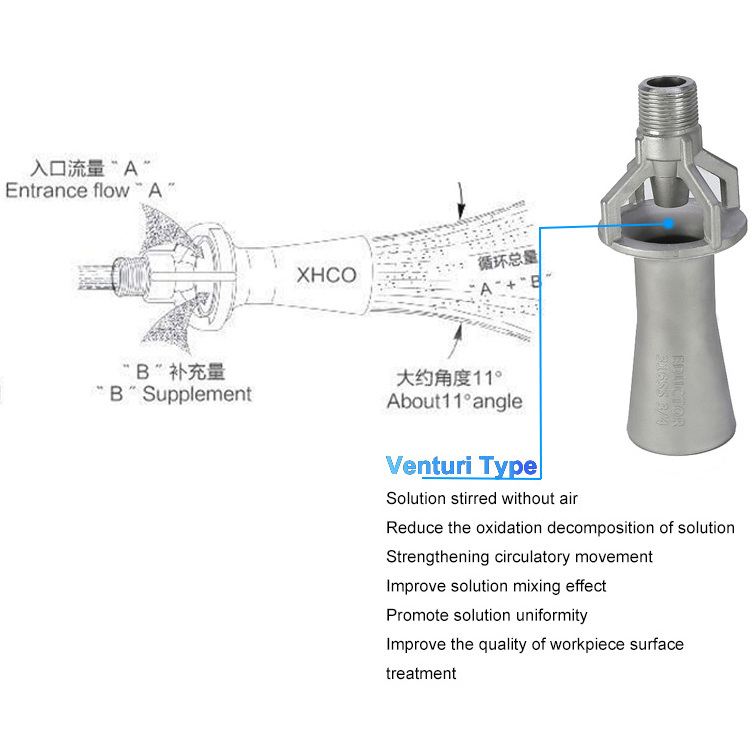

Performance feature

Specially designed nozzle that creates a stirring and circulating effect. This nozzle can mix chemicals, direct the suspended substances to a filter and prevent precipitation.

The eductor design enables the system to increase liquid flowrate by up to five times (by volume) from the tank significantly reducing the energy consumption.

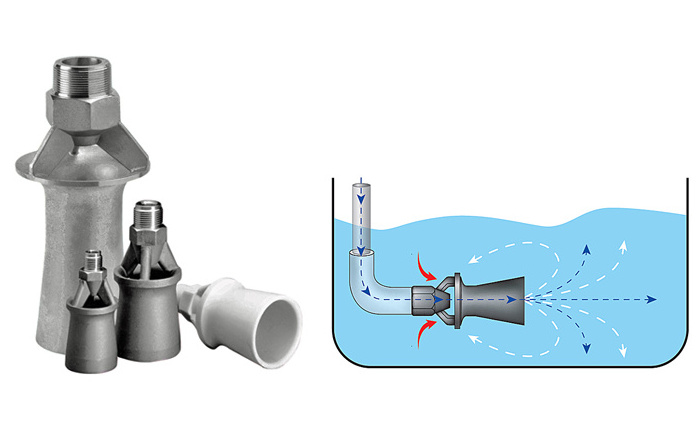

One-piece design for easy and quick installation by hand.

Recommended working pressure:0.5 kg/cm²

Flowrate tolerance:± 5%

Product details

Design Feature

1,Mixing solution without air,reduce oxidation

2,Improve mixing effect

3,Improve evenness of solution and surface processing quality of workpiece.

Material Feature:

M model mixing nozzle adopt high performance material:Carbon filter polypropylece die-casting,and stainless steel,with excellent chemical resistance,ageing resistance,max performance temperature is 120 celsuis.

In a large liquid tank, arranging the nozzles around the liquid tank is better than placing a single nozzle in the middle of the tank, causing a slight agitation below the nozzle level. The nozzles should be arranged as closely as possible and placed at the bottom of the tank, which is conducive to the maximum turnover of the liquid. Here are some typical nozzle layout examples.

The complete eductors nozzle can be connected with clamps nozzle to adjust 45 degree spray angle as blow:

Package:

● Pacakge: Standard exporting cartons or pallets

● Delivery time: Immediate delivery for products in stock

Within 10 days for customized products ( Producing time + transport time )

Delivery:

● Delivery methods: DHL, FEDEX, UPS, TNT, EMS, Air cargo, By sea