- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/220v

-

Power:

-

30kw

-

Dimension(L*W*H):

-

8500*1500*1600

-

Weight (KG):

-

1200

-

Evaporation Capacity(kg/h):

-

30kg/h

-

product name:

-

microwave dryer diagram

-

power:

-

30kw

-

Temperature range:

-

10-300

-

Usage:

-

Drying Wet Materials

-

Advantage:

-

Low Consumption High Efficiency

-

Dryig process:

-

Continuous Feeding

-

heating:

-

Electricity Etc

-

Certification:

-

CE,ISO

Quick Details

-

Type:

-

microwave dryer machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baixin

-

Voltage:

-

380v/220v

-

Power:

-

30kw

-

Dimension(L*W*H):

-

8500*1500*1600

-

Weight (KG):

-

1200

-

Evaporation Capacity(kg/h):

-

30kg/h

-

product name:

-

microwave dryer diagram

-

power:

-

30kw

-

Temperature range:

-

10-300

-

Usage:

-

Drying Wet Materials

-

Advantage:

-

Low Consumption High Efficiency

-

Dryig process:

-

Continuous Feeding

-

heating:

-

Electricity Etc

-

Certification:

-

CE,ISO

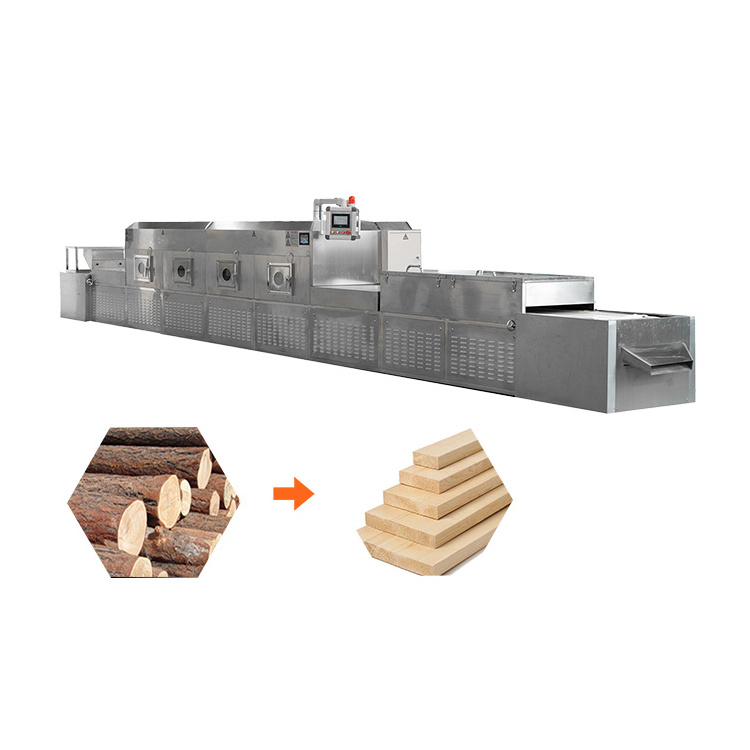

With about more than 10 years of experience on microwave dryer machine, we offer drying system which is designed to operate at low energy consumption with high reliability, smooth operation and little maintenance. Our mesh belt dryer machine is widely used in the application of food industries , and earn a good reputation from our clients.

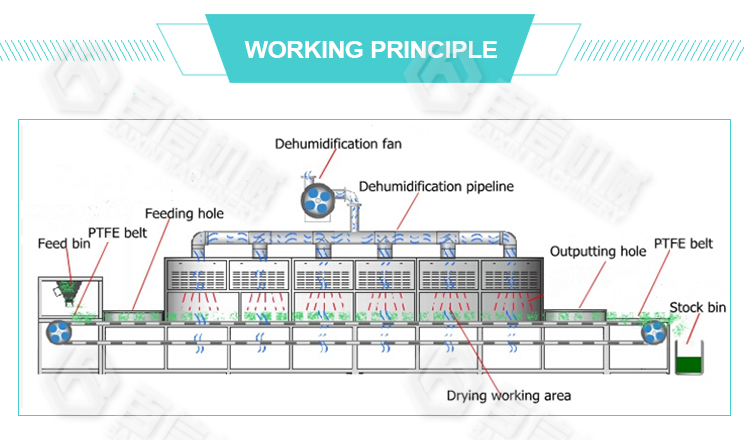

Structure of microwave dryer diagram

The microwave dryer diagram mainly contains: microwave chamber, water tower, PLC control panel, feeding part, monitoring window.

It has the function of thawing, sterilizing, curing and drying. The drying time is fast, continuous and automatic work.

Due to the different characteristic of material, Special design for microwave dryer diagram is a must to ensure the reliable operation, high dehydration capacity and highly economic efficiency.

-No need installation, the whole machine for container-type

-Continuous operation 24/7

-Short drying time, 5-10 mins

- PLC controller, and computer remote control is available

(temperature, humidity, drying time could be showed and adjusted on the screen)

-EU CE certificate is available

-

Stainless steel material for whole dryer

-Optional for air-cooled and water-cooled

-Simple operation, just connect the power.

Work principle of microwave dryer diagram

Microwaves are electromagnetic waves at a frequency of 300 MHz to 300 GHz.The material in the heating medium in the molecules of water is a polar molecule. It is the rapidly changing under high-frequency magnetic field, its polarity orientation will be with the change of external electric field changes, resulting in molecular motion and friction between the effect, this field of the microwave field can be transformed into thermal energy within the medium, the temperature of the material increased, heating and puffing a series of physical processes, to achieve the purpose of microwave heating and drying.

During the equipment is working the microwave generator produces the microwave. The materials enter into the heating chamber by conveyor. At this time, moisture and bacteria inside the material evaporate under the action of microwave energy to achieve unfreeze sterilization ripening fixing drying purpose.

microwave dryer diagram

Max. Capacity: 3000kg/h

Max Power: 300kw

| Microwave dryer technical parameters | ||||||||

| Model | Size | Power | Dewater | Cabinet | Feeding mesh width | Temperature | Controll | Voltage |

| BX-10 | 6300*665*1800mm | 10KW | 10kg/h | 2 | 500mm | 0~400℃ | PLC |

380V/415V /440V/460V |

| BX-15 | 6300*950*1800mm | 15KW | 15kg/h | 2 | 750mm | 0~400℃ | PLC | |

| BX-20 | 8500*1200*1800mm | 20KW | 20kg/h | 4 | 500mm | 0~400℃ | PLC | |

| BX-30 | 8500*1500*1800mm | 30KW | 30kg/h | 4 | 750mm | 0~400℃ | PLC | |

| BX-40 | 10500*1500*1800mm | 40KW | 40kg/h | 6 | 750mm | 0~400℃ | PLC | |

| BX-50 | 10500*2000*1800mm | 50KW | 50kg/h | 6 | 1200mm | 0~400℃ | PLC | |

| BX-60 | 10500*2000*1800mm | 60KW | 60kg/h | 6 | 1200mm | 0~400℃ | PLC | |

| BX-70 | 12500*2000*1800mm | 70KW | 70kg/h | 8 | 1200mm | 0~400℃ | PLC | |

| BX-80 | 12500*2000*1800mm | 80KW | 80kg/h | 8 | 1200mm | 0~400℃ | PLC | |

| BX-90 | 14500*2000*1800mm | 90KW | 90kg/h | 10 | 1200mm | 0~400℃ | PLC | |

| BX-100 | 14500*2000*1800mm | 100KW | 100kg/h | 10 | 1200mm | 0~400℃ | PLC | |

| BX-120 | 16500*2000*1800mm | 120KW | 120kg/h | 12 | 1200mm | 0~400℃ | PLC | |

| BX-150 | 20000*2000*1800mm | 150KW | 150kg/h | 16 | 1200mm | 0~400℃ | PLC | |

| BX-160 | 20000*2000*1800mm | 160KW | 160kg/h | 16 | 1200mm | 0~400℃ | PLC | |

| BX-180 | 22000*2000*1800mm | 180KW | 180kg/h | 18 | 1200mm | 0~400℃ | PLC | |

| BX-200 | 23400*2000*1800mm | 200KW | 200kg/h | 20 | 1200mm | 0~400℃ | PLC | |

| The drying machine can be equipped according to the user's requirement and the production demands. | ||||||||

*If any other capacity and configuration request, also could be achieved. the voltage could be customized .

1. Food:vegetables,pickles, jam,seafood and fruits.

2. Spices:chili powder, ginger powder, garlic powder, aniseed, cinnamon, angelica, cassia bark, fennel etc.

3. Grain and nuts:filbert ,peanut ,nut,almond ,pine nut ,pistachio nut ,melon seeds,grain

4. Worm:black soldier fly larva

5. Drying and sterilizing powder, granular, flakes or colloidal form foods.

6. A variety of small packaging and pet food mildew sterilization preservation.