- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

5000 KG

-

Place of Origin:

-

zhumadian

-

Voltage:

-

380V, 50/60Hz

-

Product name:

-

Juice Equipment For Juice Factory

-

Material:

-

SUS304/316

-

Capacity:

-

500-3000bph

-

Filling range:

-

2-50ml 10-150ml 30-300ml 50-500ml 100-1000ml

-

Filling volume:

-

25-250ML. 50-500ML.100-1000ML.250-2500ML

-

Suitable for:

-

Fluid Material (alll Liquid Products)

-

Filling nozzles:

-

2/4/6/8/10/12(customized)

-

Filling Liquid:

-

Easy Foaming Liquid

-

Packing material:

-

Wooden Case Packing

-

After Warranty Service:

-

1 Year Spare Parts

Quick Details

-

Machinery Capacity:

-

500-3000bph

-

Brand Name:

-

zyl

-

Year:

-

2023

-

Weight:

-

5000 KG

-

Place of Origin:

-

zhumadian

-

Voltage:

-

380V, 50/60Hz

-

Product name:

-

Juice Equipment For Juice Factory

-

Material:

-

SUS304/316

-

Capacity:

-

500-3000bph

-

Filling range:

-

2-50ml 10-150ml 30-300ml 50-500ml 100-1000ml

-

Filling volume:

-

25-250ML. 50-500ML.100-1000ML.250-2500ML

-

Suitable for:

-

Fluid Material (alll Liquid Products)

-

Filling nozzles:

-

2/4/6/8/10/12(customized)

-

Filling Liquid:

-

Easy Foaming Liquid

-

Packing material:

-

Wooden Case Packing

-

After Warranty Service:

-

1 Year Spare Parts

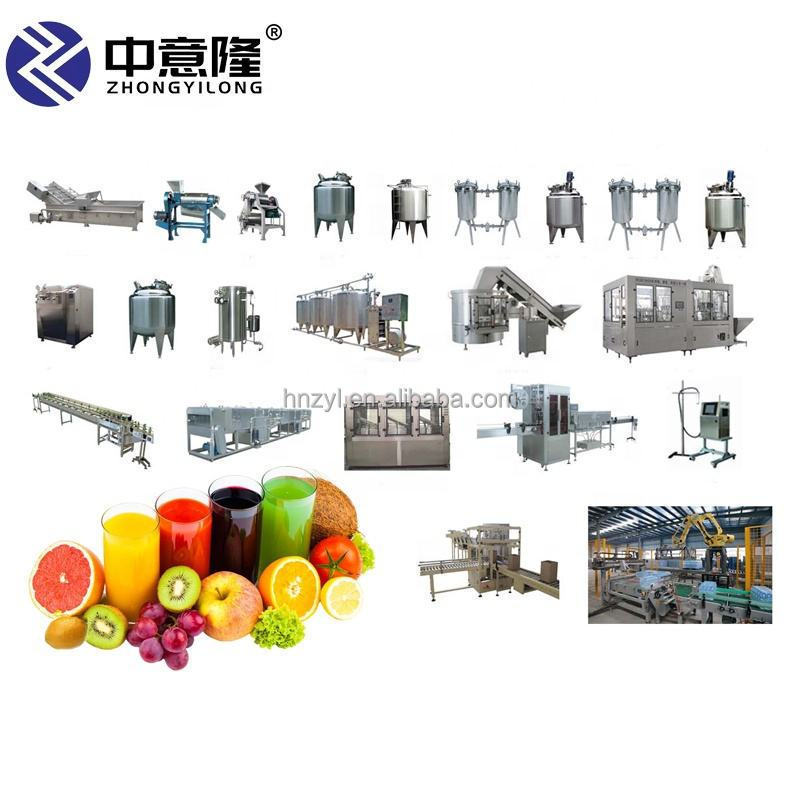

zhongyilong is a professional manufacturer of beverage machinery in China.Our main products have: Water filling production line, juice filling production line, carbonated drinks production line, and also aerosol filling machine, 5 Gallon bottle filling production line, and all other auxiliary equipment. Our engineers are located all over the world and can provide safe and fast service to your beverage production solutions in your country.

Our company is committed to the complete line of the fruit juice production. The whole fruit juice production line is widely applicable to produce apple juice, blueberry juice, orange juice, pineapple juice, orange juice, mango juice, lemon juice, cherry juice, prune juice, cranberry juice, carrot juice, kiwi juice, peach juice, pear juice, and strawberry juice, etc. we provide a comprehensive range of services right from processing and storage to transport and packing of various kinds of shape and style, in order to offering the specific juice with original nutrition, color, and flavor of the fruit.

Features of Fruit Juice Processing Line

* Advanced technology, energy & water saving.

* Advanced technology, energy & water saving.

* SUS304/316L material, high qualified component of world famous brand.

*Semi-automatic and fully automatic system for your choice.

* Customized turn-key solution including installation, commissioning at your side.

* The finished product quality is excellent, beautiful color and tasty.

* High productivity, flexible production, can be customized according to customer demand.

* Complete supervision system, equipped with control room to monitor each processing stage.

* Daily output can be clearly record.

|

Raw material

|

Pure water / fruit juice/ concentrated juice

|

|

|

|

|||

|

Final products

|

Energy drinks/ carbonated juice drinks/ fruit juice/ juice beverage

|

|

|

|

|||

|

Products packaging

|

Plastic bottle , glass bottle, cans, pouch

|

|

|

|

|||

|

Capacity

|

300-5000L/H

|

|

|

|

|||

|

Plant area required

|

500-2000㎡

|

|

|

|

|||

|

Loss rate

|

Not more than 3%

|

|

|

|

|||

|

Equipment production cycle

|

About 40 days

|

|

|

|

|||

Product Description

Description of Fruit Juice Processing Line

1. Almost all seasonal fruits and vegetables can be processed to fruit juice and drinks.

1. Almost all seasonal fruits and vegetables can be processed to fruit juice and drinks.

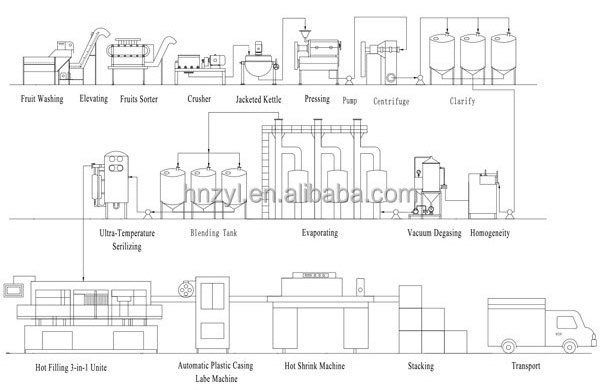

2. The fruit juice processing line mainly includes: washing and sorting system, juice extracting system, enzymatic hydrolysis and filtration system, mixing and blending system, sterilizing system, finished product filling and packing system, auxiliary energy system.

3. Fruit juice processing line capacity can be customize from 60 tons/day~480 tons/day.

4. Filling speed: about 2000~32000 bottles/cans per hour, packages can be customized on your target market.

.

Product details

Fresh Juice Filling Machine Production Line

This filling machine production line is consisted with RO water treatment system,fruit cleaning machine,

juice extractor, vibrating filter

,

steam kettle, s

terilization machine,

bottle washing machine,

filling machine, capping machine, automatic labeling machine.

This filling machine production line is suitable for fresh juice (apple,

pineapple,orange,

mango) making and filling, tomato paste or ketchup making and filling, and so on.

All machines in the production line can be customized according to the customer's requirements.

RO Water Treatment System

The purification of pure water directly affects the quality and taste of products. The water purification rate of our water treatment equipment is as high as 99.7%, and all the equipment are made of food grade stainless steel with long service life. RO membrane uses imported hydergic membrane.

Vacuum degassing equipment and homogenizer

Vacuum

degassing equipment

adopts vacuum system to remove the smelly and oxygen in the juice.This equipment is composed of degassing part, condensing part, vacuum pump, etc; It is widely used in juice industry.

The high pressure homogenization machine is the special equipment for the homogeneous refinement and high pressure transportation of liquid materials.

Juice mixing system

Food grade stainless steel, with heating jacket and liquid level gauge, with operating platform, can customize all kinds of mixing paddles and motors. It is mainly used for mixing juice, sugar and other additives, and for quantitative addition of water.

Ultra high temperature sterilization machine

Ultra high temperature instantaneous sterilization machine temperature at 115°C-135°C.

Sterilization before product filling ensures product quality and extends shelf life. The equipment automatically controls sterilization temperature and duration. Materials flow in a closed-loop space to avoid secondary pollution.

Automatic Labeling Machine

There is different labeling machines according to your bottles and sticker position ,1 such as round bottle labeling machine, square bottles single side labeling machine , two sides labeling machine , top and sides labeling machine ,feeding and capping machine and so on.

There is different labeling machines according to your bottles and sticker position ,1 such as round bottle labeling machine, square bottles single side labeling machine , two sides labeling machine , top and sides labeling machine ,feeding and capping machine and so on.

Automatic printing machine

You can choose the hot ribbon printer , inkjet print ,laser printer and so on

You can choose the hot ribbon printer , inkjet print ,laser printer and so on

Why Choose Us

All of our filling lines have CE certifications , 1 year warranty ,free accessories ,online operation guide

If you are interested in this Filling lines,please contact us.

Related Products

About us

Thanks for your inquiry on Alibaba. ZHONGYILONG Machienry have been specializing in food&beverage processing line for over 20 years and successfully set up 300 factories for demestic and international customers.

we are a high-tech manufacturing enterprise focusing on automatic packaging production equipment for food, beverage. We can customize beverage production line process and formula according to customer's demand.

Our business scope covers dairy products, carbonated beverages, wine, beer, fermented beverages tomato paste, porridge, mixed juice drinks, vitamin functional drinks, pure water.cooking oil production lines, etc.

We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

We look forward to your inquiry and exchange cooperation.

To generally understand your requirement and facilitate our further communication, we'd like to know from you:

1.Will this be your own business or you are trading company?

2.what will be the scale of this project: home-scale ,commerical-scale or government procurement?

3.By which process: you already have process flowchart or we design for you?

4.what's the final products?

package and product specification detail

5.what's the estimated capacity?

input of raw material or output of final products, how much, by hour/daily or annual?

6.What's stage of this project are you in?

gathering information for future inspection

or want to finish this project in half or one year?

Please kindly understand that we will work very closely with you to offer an turn key solution.So firstly we should fully comprehend your situation in order to make out a reasonable project scheme with affordable cost.

Looking forward to your early response.

Thanks&best regards

Customer Photos

FAQ

Q1: Where is your factory? How can I visit your factory?

A: Our factory is located in Henan Province. If you have a travel plan, we warmly welcome you to visit our factory.

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine.

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine.

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, Money Gram and cash payment .

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine.

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine.

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, Money Gram and cash payment .

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Hot Searches