- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TSE65-III and so on

-

Dimension(L*W*H):

-

17000*1200*2500 mm

-

Weight:

-

4000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v / 50Hz , etc

-

Power:

-

35kw

-

Application:

-

Warehouse

-

Product name:

-

Breakfast Cereal Production Line

-

main material:

-

stainless steel

-

Screws:

-

38# CrMOAL

-

Food types:

-

extrusion snacks

-

output:

-

100-150 kg/h and so on

-

Usage:

-

Instant Cereal Corn Flakes Machine

-

Certification:

-

CE , ISO9001

Quick Details

-

Machinery Capacity:

-

100kg/h - 500kg/h

-

Brand Name:

-

Sunward

-

Year:

-

2022

-

Model Number:

-

TSE65-III and so on

-

Dimension(L*W*H):

-

17000*1200*2500 mm

-

Weight:

-

4000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v / 50Hz , etc

-

Power:

-

35kw

-

Application:

-

Warehouse

-

Product name:

-

Breakfast Cereal Production Line

-

main material:

-

stainless steel

-

Screws:

-

38# CrMOAL

-

Food types:

-

extrusion snacks

-

output:

-

100-150 kg/h and so on

-

Usage:

-

Instant Cereal Corn Flakes Machine

-

Certification:

-

CE , ISO9001

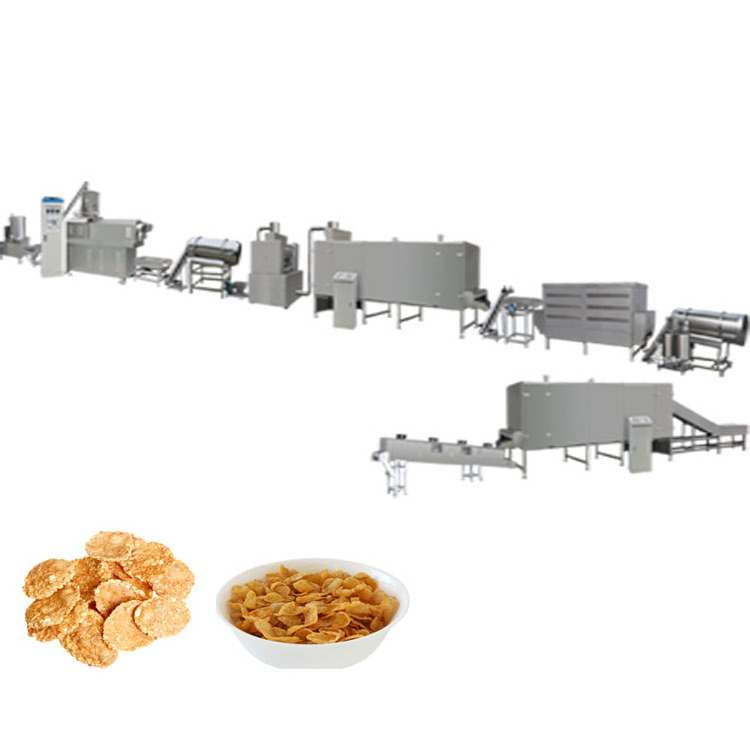

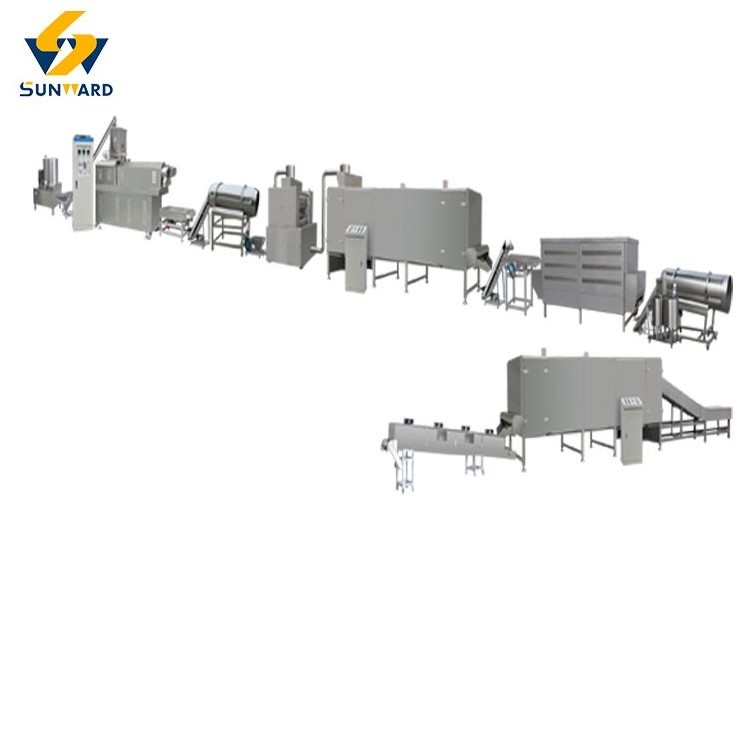

Corn Flakes For Breakfast Cereal Production Line Cocoa Cereal Making Machinery

1. Process of breakfast cereal production line:

Mixing system→ Extruding system→ Drying system→Secondly inflating system →Flavoring system→ Drying system→ Packing system

2. Products of breakfast cereal production line are different shapes of corn flakes,puffed snacks , fried snacks, core filling snacks and so on.

3.Function of breakfast cereal production line: corn flake can be produced by controlling the high temperature and high pressure.

4.Raw materials :

Breakfast cereal production line adopts corn flour, rice powder, wheat flour as main raw materials.

5. Output of breakfast cereal production line can be 100kg/h-150kg/h, 200kg/h-260kg/h, 300kg/h-500kg/h and so on.

6.Voltage :

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

7. All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

Jinan Sunward Machinery Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system,soy nuggets system; as well as pet food/fish food system.

-- Before sale service

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

--Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout

2.Welcome to visit our factory or the domestic clients' factory.

3.Inspect the machine before leaving the factory.

--After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula.

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. 1-2 engineers will be arranged for customer