- Product Details

- {{item.text}}

Quick Details

-

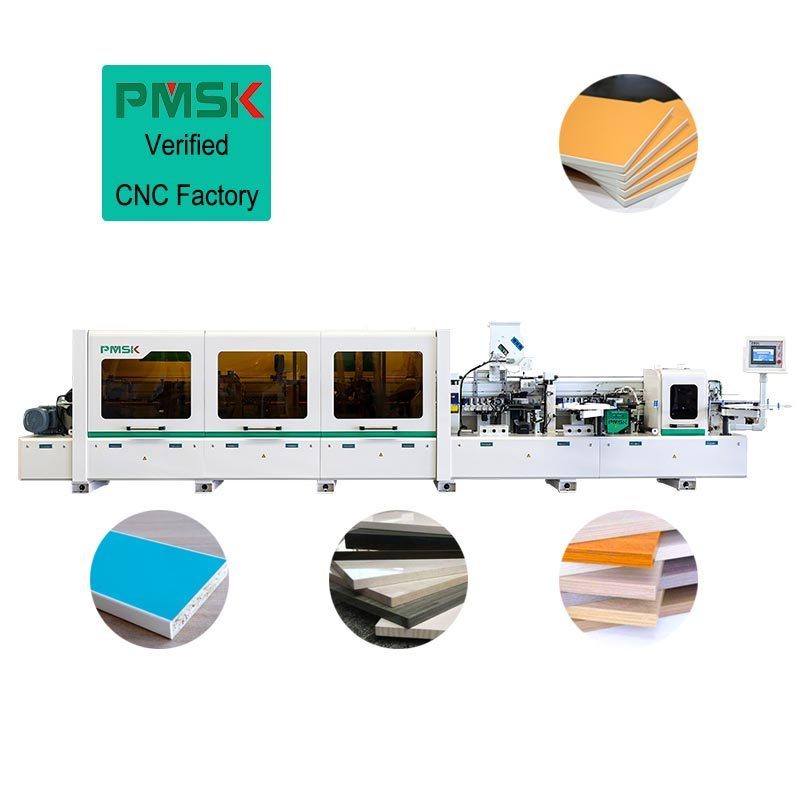

Dimension(L*W*H):

-

6600X1050X1750mm

-

Power (kW):

-

12.5

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

26m/min

-

keywords:

-

Particle Board Production

-

Edge tape width:

-

12-65mm

-

Edge thickness:

-

0.4-3mm

-

Working pressure:

-

0.7mpa

-

Panel Width:

-

10-60mm

-

Belt material:

-

PVC, ABS, WOOD etc.

-

Gluing:

-

EVA and Pur quick soling

-

Customizable function:

-

vertical slot, side hole, bevel edge banding

-

After-Sales Service:

-

Free Replacement Parts

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

pmsk

-

Voltage:

-

AC380V/3PH/50HZ

-

Dimension(L*W*H):

-

6600X1050X1750mm

-

Power (kW):

-

12.5

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

26m/min

-

keywords:

-

Particle Board Production

-

Edge tape width:

-

12-65mm

-

Edge thickness:

-

0.4-3mm

-

Working pressure:

-

0.7mpa

-

Panel Width:

-

10-60mm

-

Belt material:

-

PVC, ABS, WOOD etc.

-

Gluing:

-

EVA and Pur quick soling

-

Customizable function:

-

vertical slot, side hole, bevel edge banding

-

After-Sales Service:

-

Free Replacement Parts

Products Description

Our september expo deals start now

Activity time: September 1 - September 30

Give Back To New And Old Customers

(10%off)

Welcome To Be Our Overseas Agent.

(30%off)

Free Replacement Parts (Within 3 Years)

(100%off)

The machine guarantee is

2 Years

,

24 hours

t

echnical support online.

We have agents all over the world, which can be installed and trained on site .

We have agents all over the world, which can be installed and trained on site .

And so on....

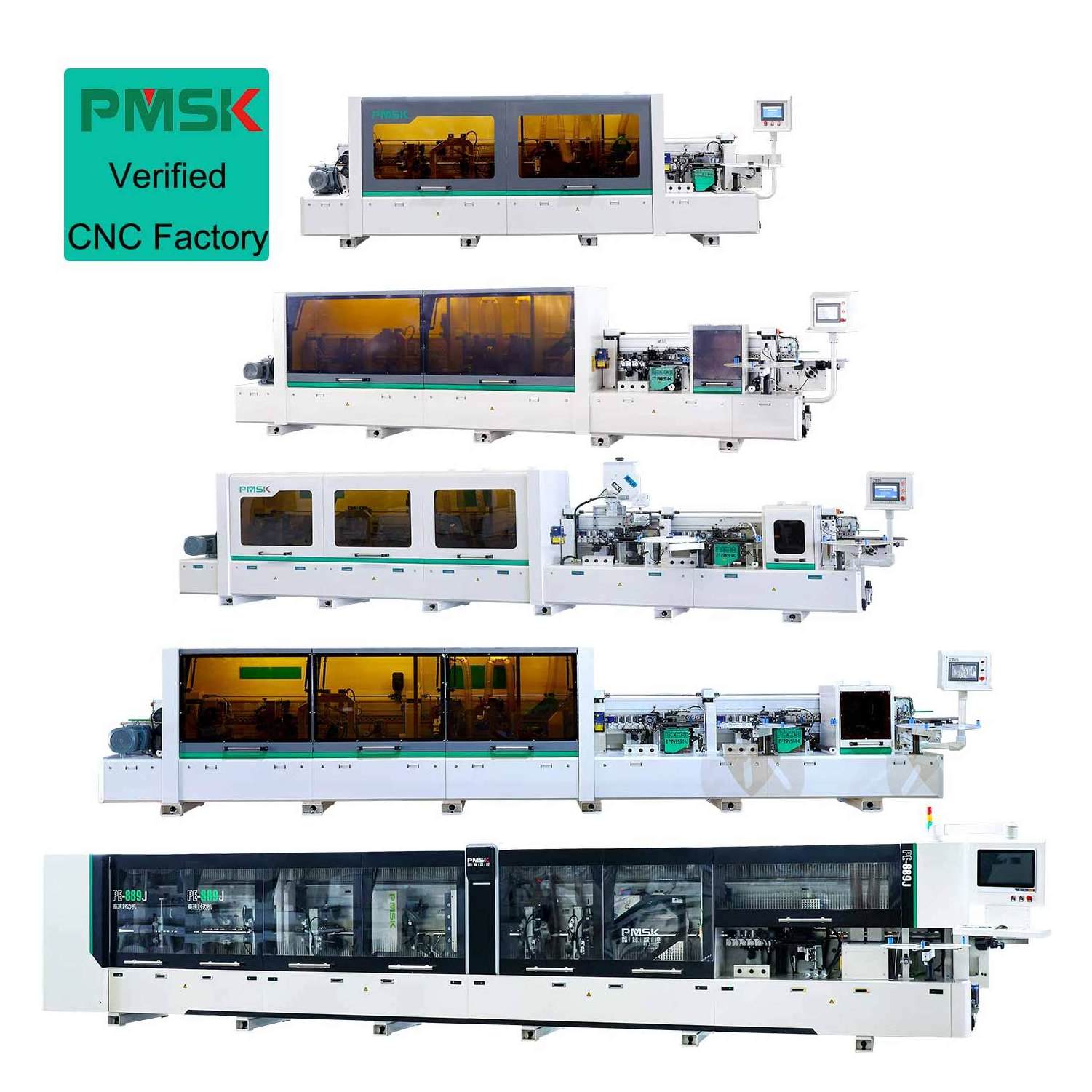

We are a factory. There are many models for you to choose from, and we can also customize them according to your requirements.

Examples: vertical slot, side hole,

bevel

edge

banding

and so on.

Please contact us now.

Pe668 (9 Functions)

1 Pre-milling, 2 Gluing, 3 Cutting start and end points, 4 Roughing finishing, 5 Fine finishing, 6 Rounded corner , 7 Scraping, 8 Cleaning agent, 9 Polishing.

Pe668j (11 functions)

1 Separating agent, 2 Pre-milling, 3 EVA glue, 4 Multi-wheels pressing, 5 Cutting start and end points, 6 Rough trimming, 7 Fine trimming , 8 Corner trimming, 9 Scraping , 10 Cleaning agents, 11 Polishing

Pe668j-1 (14 functions)

1 Separating agent, 2 Pre-milling, 3 EVA glue, 4 Multi-wheels pressing, 5 EVA gluing device, 6 Multi-wheels pressing, 7 Cutting start and end points, 8 Rough trimming, 9 Fine trimming , 10 Corner trimming, 11 Scraping , 12 Cleaning agents, 13 Polishing one, 14 Polishing two.

Pe669 (14 functions)

1 Infrared baking lamp, 2 Separating agent, 3 Pre milling, 4 Quick soling, 5 Multi wheels pressing, 6 Front and end cutting, 7 Rough trimming, 8 Pneumatic fine trimming, 9 4 Heads corner trimming, 10 Double pneumatic scraping, 11 Off-cut, 12 Flat scraping, 13 Cleaning agent, 14 Double pneumatic Buffing.

CNC Woodworking Machines MANUFACTURER 10 YEARS

For more functional customization, please contact us.

|

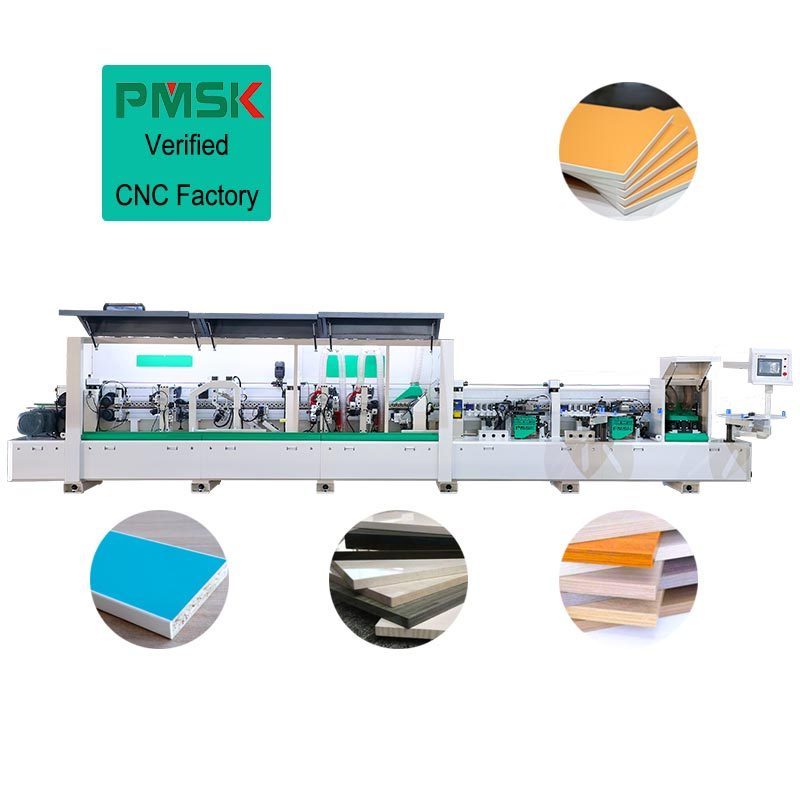

Model

|

pe-668 Edge Banding Machine

|

|

Edge tape thickness

|

0.4-3mm

|

|

Edge tape width

|

12-65mm

|

|

Panel thickness

|

10-60mm

|

|

Feeding speed

|

0-23m/min

|

|

working air pressure

|

0.7Mpa

|

|

Total power

|

12.5kw

|

|

equipment weight

|

2500kg

|

|

Dust extraction

|

∅100mm *5 pieces

|

|

overall size

|

6600*1050*1750mm

|

What Is An Edge Banding Machine?

An edge banding machine is an automated woodworking machine that carries out pre-milling, gluing, end trimming, rough trimming, fine trimming, corner trimming, scraping, cleaning separation for cabinets and furniture making. The automatic edge bander is designed for straight edge banding and trimming of MDF (medium density fiberboard), blockboard, solid wood board, particle board, polymer door panel, melamine, and plywood.

Feature:

In addition, we can also customize: vertical slot, side hole, bevel edge sealing and so on.

FAQ

1,I need a CNC router,can you give me some suggestions?

A,Sure,we will give suggestions of the most suitable machine,Before that,we need to know some information,such as effective processing area,materials,etc.,to getermine the main parameters. in addition,Our machines can be customized according to buyers’ request.

2,Which kind of materials can be processed on this machine?

A:Wood,mdf,stone,acrylic,glass,plastic,foam,aluminium,copper,and almost all kinds of non-steel materials.We have free training online. If there is big trouble with your machine in the warranty time, we can repair it.

3,Are you a factory or trading company?

A:We are the manufacturer and we have 15 years factory experience.As only the machine made by ourself,the quality can be tursted,and the most important thing is that we can do better after-sales service.We know how to fix the problem of every part easliy,so welcome to visit to our factory.

4,How should i pay for my order?

A:You need to pay 30% as prepayment at first,then we will start to make production.When the machine is completed,we will send pictures or videos to you,and then you need to pay the balance.We will ship the machine to you after we receive your full payment.

5,How long is the delivery time?

A:For standard machines,it will be 1-3 days;For non-standard machines and customized machines according to client' specific requirements,it will be 10 to 15 days.

Hot Searches