- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

300kg-9500kg

-

Size:

-

different as each model

-

Power:

-

different as each model

-

Weight (KG):

-

1000 kg

-

Product name:

-

POLYMER DOSING SYSTEM

-

Function:

-

auto polymer preparation

-

OEM:

-

New

-

Application:

-

Manufacturing Plant,Printing Shops,Wastewater Treatment

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Water Master, Water Master

-

Material:

-

Plymood Csase

-

Weight:

-

300kg-9500kg

-

Size:

-

different as each model

-

Power:

-

different as each model

-

Weight (KG):

-

1000 kg

-

Product name:

-

POLYMER DOSING SYSTEM

-

Function:

-

auto polymer preparation

-

OEM:

-

New

-

Application:

-

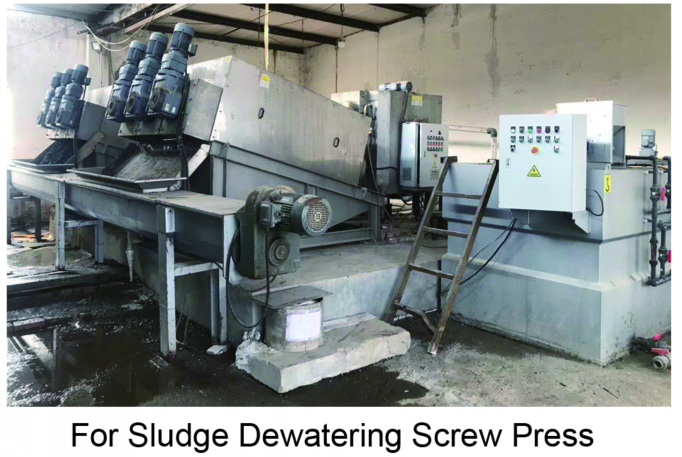

Manufacturing Plant,Printing Shops,Wastewater Treatment

-

After Warranty Service:

-

Video technical support

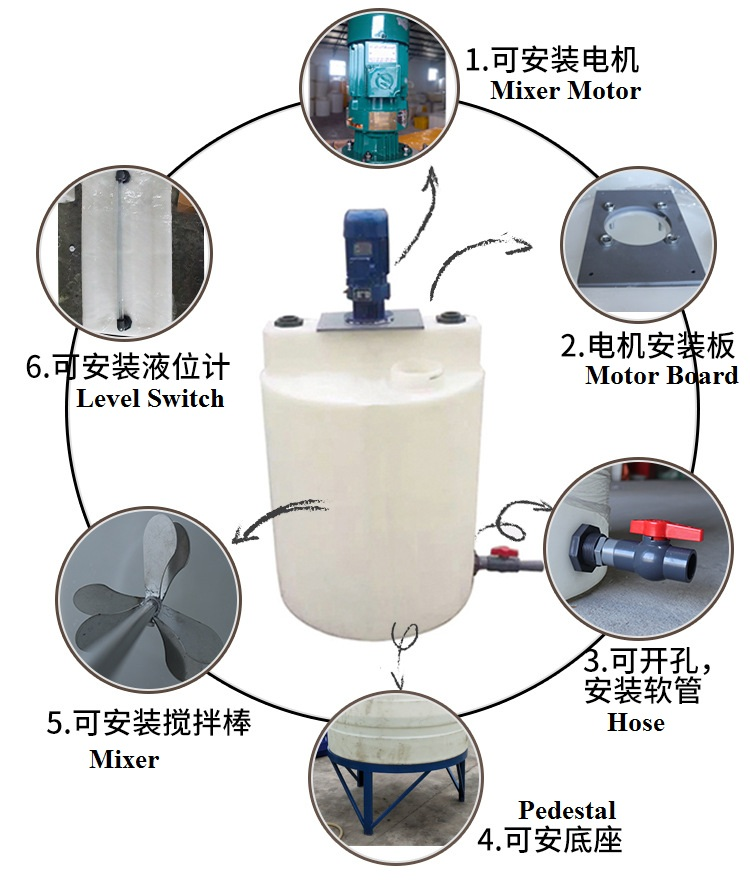

Products Description

Dosing Sysetm is widely used in water treatment for mixing, dissolving and storing various chemicals, and then adding the liquid chemicals to each dosing point through a metering pump or a water ejector. The shape of the dosing tank could be square and round, and the material is polyethylene (PE). It is formed by rotomolding technology at one time. The installation position of the metering pump and the mixer is preset on the upper part. The mixer, the dosing tank and the metering pump are three in one. It is very convenient to use.

Product Paramenters

|

Tank Volume

|

Size

|

Impeller&Shaft Material

|

Shaft Dia.

(mm) |

Shaft Length

(mm) |

Mixer

|

|

200L

|

Φ550*900

|

SS304/CS+Epoxy painted/SS316L

|

Ф200

|

L=700

|

BD09-11-0.75kW

|

|

300L

|

Φ650*960

|

SS304/CS+Epoxy painted/SS316L

|

Ф200

|

L=800

|

BD09-11-0.75kW

|

|

500L

|

Φ800*1100

|

SS304/CS+Epoxy painted/SS316L

|

Ф200

|

L=900

|

BD09-11-0.75kW

|

|

1000L

|

Φ1030*1250

|

SS304/CS+Epoxy painted/SS316L

|

Ф300

|

L=1000

|

BD09-11-0.75kW

|

|

1500L

|

Φ1200*1500

|

SS304/CS+Epoxy painted/SS316L

|

Ф300×2

|

L=1200

|

BD09-11-0.75kW

|

|

2000L

|

Φ1300*1700

|

SS304/CS+Epoxy painted/SS316L

|

Ф300×2

|

L=1300

|

BD10-11-1.1kW

|

|

3000L

|

Φ1500*1800

|

SS304/CS+Epoxy painted/SS316L

|

Ф400×2

|

L=1600

|

BD10-11-1.5kW

|

|

5000L

|

Φ1760*2200

|

SS304/CS+Epoxy painted/SS316L

|

Ф600×2

|

L=1900

|

BD11-17-2.2kW

|

|

6000L

|

Φ1800*2600

|

SS304/CS+Epoxy painted/SS316L

|

Ф600×2

|

L=2400

|

BD11-17-2.2kW

|

Features

1. Continuously working with 3-tank integration design

2. With powdered or liquid state (optional) dual feed design to meet different needs.

3. With uniform and moderate concentration to reduce the agglomeration causing by the improper manual allocation. Blocking of pipe or pump,

4. Powder feeding hopper with anti-condensation, heating and insulation function can avoid the agglomeration or deterioration

5. Unique design of automatic intermittent operation and cross mixing function at stand-by time makes the uniform solution always working in the best condition

Working Principle

Application

Product packaging

Hot Searches