7.High cost performance, withCNC routerand curing platform,The processing technology is simple and machine is easy to operate. It is a basic equipment for processing channel letter and outdoor sign and software is easy to learn.

- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

Roller-Bending Machine

-

Raw Material:

-

Sheet / Plate Rolling

-

Power:

-

CNC

-

Extra Services:

-

Slotting & Notching

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

machine:

-

led letter sign making bender machine

-

keyword:

-

sign making machine

-

the width of sheet:

-

20-100mm

-

working thickness:

-

0.6 mm

-

suitable materials:

-

trimless aluminum sign making

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DRIVE cnc

-

Weight (KG):

-

280

-

Machine Type:

-

Roller-Bending Machine

-

Raw Material:

-

Sheet / Plate Rolling

-

Power:

-

CNC

-

Extra Services:

-

Slotting & Notching

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

machine:

-

led letter sign making bender machine

-

keyword:

-

sign making machine

-

the width of sheet:

-

20-100mm

-

working thickness:

-

0.6 mm

-

suitable materials:

-

trimless aluminum sign making

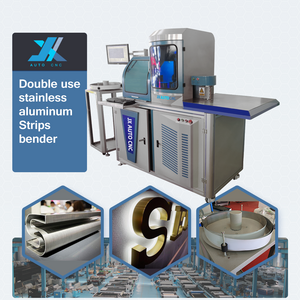

CNC Channel Letter Flanging Bending Machine

Aluminum and Stainless Steel Letter Bending Machine

|

MODEL

|

A-200

|

|

Function

|

Automatic feeding,slotting and bending

|

|

Applicable Materials

|

Folded alu , flat alu , profile alu and profile with PVC and foam

|

|

Material Width

|

20-200mm

|

|

Materials Thickness

|

0.5-1.2mm

|

|

Feeding system

|

Rolling -typed continuous feeding system

|

|

Slotting system

|

Milling cutter double side arbitrary angle slotting system

|

|

Bending system

|

Double roller bearing extruding bending system

|

|

Accuracy

|

±0.1mm

|

|

Bending Radius

|

≥7 mm

|

|

Input file format

|

PLT,DXF,AI,

|

|

Power

|

AC 220V/50HZ/ 3KW

|

|

Air supply

|

0.6MPA

|

|

Control system

|

Leetro CBS4

|

|

Weight

|

350kgs

|

|

Packing size (mm)

|

L2150*W650*H1500

|

|

MODEL

|

B-130

|

|

Function

|

Automatic feeding,slotting and bending

|

|

Applicable Materials

Alu= aluminum |

Folded alu , flat alu

|

|

Material Width

|

20-130mm

|

|

Materials Thickness

|

0.5-1.2mm

|

|

Feeding system

|

Rolling -typed continuous feeding system

|

|

Slotting system

|

Milling cutter double side arbitrary angle slotting system

|

|

Bending system

|

Double roller bearing extruding bending system

|

|

Accuracy

|

±0.1mm

|

|

Bending Radius

|

≥7mm

|

|

Input file format

|

PLT,DXF,AI,

|

|

Power

|

AC 220V/50HZ/ 3KW

|

|

Air supply

|

0.6MPA

|

|

Control system

|

ADT

|

|

Weight

|

150kgs

|

|

Packing size (mm)

|

L1650*W700*H1150

|

|

Hardware

|

Feeding system

|

Precision screw transmission and mechanical arm alternatively feeding structure (closed loop self-test system)

|

|

|

Slotting system

|

Hard alloy planer

|

|

|

Notching structure

|

Notching by air cylinder

|

|

|

Flanging structure

|

Pneumatic flanging by air cylinder

|

|

|

Bending system

|

Double -pole alternate part-arc institution and patented alternative arc-extrusion structure

|

|

|

Driving motor

|

Servo motor 3 set; stepper motor 1 set

|

|

|

Weight

|

800kg

|

|

|

Dimensions

|

Body:L2140mm*W700mm*H1560mm;Feeding tableL500mm*W500mm*H1100mm

|

|

Performance

|

Material category

|

Flat aluminum /Stainless steel / Galvanized plate (height: 20-180mm)

|

|

|

Material thickness

|

Flat aluminum :0.6 -1.5 mm/ SS : 0.3-1.2mm / Galvanized sheet: 0.4-1.2mm

|

|

|

Flanging thickness

|

Flat aluminum 0.8mm

|

|

|

Notching angle

|

30° / 120°

|

|

|

Flanging width

|

10mm

|

|

|

Support format

|

Al / PLT / DXF / NC

|

|

|

Feeding accuracy

|

Length j+0.1mm Radius > 4mm

|

|

Software

|

Control card

|

Leetro Four -axis motion control card

|

|

|

Software system

|

Auto drive / CBS4 auto bending system

|

|

|

Input voltage

|

220V 50Hz 3Kw

|

|

|

Air pressure

|

0.6-0.8Mpa

|

|

Hardware

|

Feeding system

|

Rolling continuous feeding mechanism

|

|

|

Slotting system

|

Planner tool

|

|

|

Bending system

|

Double axis coupling bending system

|

|

|

Driving motor

|

Two -phase stepper motor 2 set

|

|

|

Equipment weight

|

50 KG

|

|

|

Dimensions

|

L1360*W510*H780mm

|

|

Performance

|

Material category

|

Flat aluminum (20-100mm)

|

|

|

Material thickness

|

0.6 mm

|

|

|

Support format

|

PLT / DXF

|

|

|

Feeding accuracy

|

Length + 0.1mm Radius > 10mm

|

|

Software

|

Control card

|

Four -axis motion control card

|

|

|

Software system

|

Auto drive bending system

|

|

|

Input voltage

|

220V 50Hz 500KW

|

|

|

Air pressure

|

0.6-0.8Mpa

|

1. Whole machine is made of stainless steel metal sheet , there is no special condition about work place. It is especially suitable for s

mall store and sign factory

mall store and sign factory

2. Using planer tool slotting structure, the single-sided slotting efficiency is higher. Compared with the double-sided slotting, it can effectively protect the paint surface of material and maintain the appearance of the processed shell

3.Rollingcontinuous feeding structure, fast response speed, closed-loop self-test system, using high-quality encoder, it will make sure that feeding system is right all the time.

4.Material height scale, which can help you quickly positioned when you need to change another material to process,It will make sure

that cutting straightness of the material during machine working

that cutting straightness of the material during machine working

5. Single rail pneumatic lifting slotting structure,ensure the stability and straightness of the planer cutting. At the same time, it has low noise during machine processing , which is conducive to get a good working environment.

6.

Double-axis linkage arc bending structure, which has fast bending speed and good bending forming effect

Packing & Delivery

wooden case

Hot Searches