- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

guangmao machinery

-

Voltage:

-

380v/50hz/3phase

-

Power:

-

700kw

-

Dimension(L*W*H):

-

12.44m*7.3m*5.7m

-

Weight:

-

60tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

color:

-

optional

-

design:

-

newest technology

-

material:

-

stainless steel

-

experience:

-

36 years

-

raw material:

-

virgin pulp, waste paper

-

spare parts:

-

free

-

control method:

-

PLC

-

bearing:

-

NSK,INA,FAG available

-

Application:

-

paper Industry

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United States, Viet Nam, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

Other

-

Processing Type:

-

paper product making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

guangmao machinery

-

Voltage:

-

380v/50hz/3phase

-

Power:

-

700kw

-

Dimension(L*W*H):

-

12.44m*7.3m*5.7m

-

Weight:

-

60tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

color:

-

optional

-

design:

-

newest technology

-

material:

-

stainless steel

-

experience:

-

36 years

-

raw material:

-

virgin pulp, waste paper

-

spare parts:

-

free

-

control method:

-

PLC

-

bearing:

-

NSK,INA,FAG available

-

Application:

-

paper Industry

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United States, Viet Nam, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

ISO9001:2008

China paper mills 2800mm soft tissue toilet paper making machine, cotton pulp towel manufacturing production line for sale

I . Technical parameter:

1. Raw material: waste paper, virgin pulp

2. Output paper style: toilet paper,tissue paper

3. Output paper weight: 15-30gsm (can be adjusted)

4. Net paper width: 2800mm;

5. Capacity:10tons per day (24 hours)

6. Width of cylinder mould: 3200mm;

7. Bearing center-center: 3700mm;

8. Design speed: 180m/min

9. Working speed: 82-165m/min

10. Drive way: Alternating current, frequency conversion, speed control, section drive;

II

.

Structure and characteristic of main part :

1. Cylinder section: φ 1800mm stainless steel cylinder mould 1 set, φ 550mm couch roll 1 set, coated by rubber, rubber shore hardness 38 ± 2.

2. Dryer section: φ 3000mm dryer can1 set, φ 600mm touch roll 1 set, coated by rubber, rubber shore hardness 90 ± 2.

3. Drive way: Alternating current, frequency conversion, speed control, section drive;

5. Pneumatic compression device

.

III .Paper making machinery and power list:

| No. | Item | Power(kw) | Qty(set) | Total power(kw) |

| Pulp making production line (total power is 513.9kw) | ||||

| 1 | High consistency hydrapulper | 110kw | 1 | 110kw |

| 2 | F1 pulp pump | 7.5kw | 8 | 60kw |

| 3 | φ750 Thruster | 7.5kw | 7 | 52.5kw |

| 4 | Fiber separator | 22kw | 1 | 22kw |

| 5 | white water pump | 30kw | 1 | 30kw |

| 6 | R1 pulp pump | 37kw | 2 | 74kw |

| 7 | D1 pulp pump | 11kw | 1 | 11kw |

| 8 | SG-A1 pulp pump | 4kw | 1 | 4kw |

| 9 | Pressure screen | 30kw | 1 | 30kw |

| 10 | Vibrating screen | 3kw | 1 | 3kw |

| 11 | High speed pulp washer | 7.5kw | 1 | 7.5kw |

| 12 | φ380 Double-disc refiner | 37kw | 2 | 74kw |

|

13 |

Pulp concentration control instrument | 2.2kw+0.2kw | 1 | 2.4kw |

| 14 | 0.6 Model pressure screen | 7.5kw | 1 | 7.5kw |

| 15 | M1 pulp pump | 11kw | 1 | 11kw |

| 16 | Hot water pump | 7.5kw | 1 | 7.5kw |

| 17 | Multi-stage pulp pump | 7.5kw | 1 | 7.5kw |

| Paper making production line (total power is 165.3kw) | ||||

| 1 | Dryer part | 90kw | 1 | 90kw |

| 2 | Reeling machine | 11kw | 1 | 11kw |

| 3 | Exhaust fan | 0.2kw | 4 | 0.8kw |

| 4 | Axial-flow ventilator | 7.5kw | 2 | 15kw |

| 5 | Vacuum pump | 15kw | 2 | 30kw |

| 6 | Air compressor | 18.5kw | 1 | 18.5kw |

Toilet tissue paper workshop for our client: Cylinder Mould Part + Dryer Can Part + Exhaust Hood + Reeling Part + Chemical Tank + Electric Control Cabinet

Raw material for making toilet tissue paper: waste paper, virgin pulp

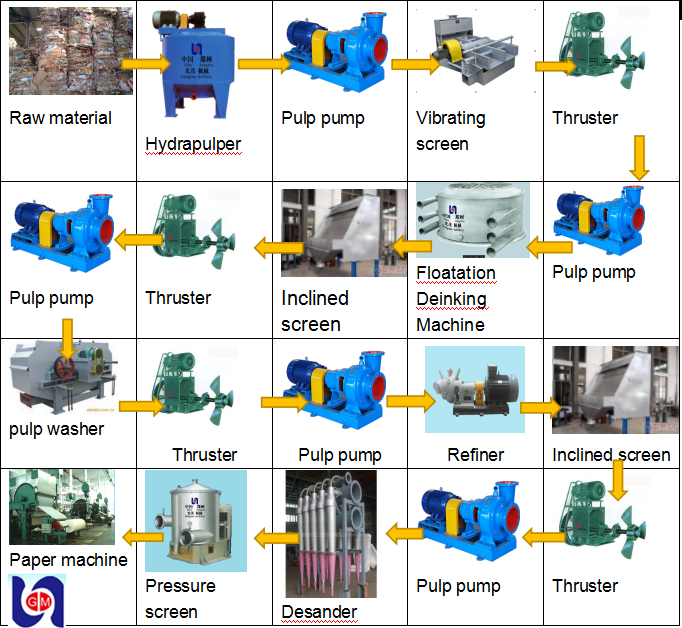

Toilet tissue paper making process:

Pulp making equipments: Hydrapulper, Vibrating Screen, Pulp Refiner, Pulp Bleaching Machine, Propeller, Desander, Pulp pump.

Paper making machinery spare parts: Main frame, Foundation plate, Cyliner mould, Net cage, Dryer cylinder and exhaust hood, Boiler, Guide roll, Couch roll, Electric control cabinet.

Toilet tissue paper processing machinery: jumbo roll rewinding machine, slitting machine, napkin folding machine, cutting machine, packing machine etc.

Toilet tissue paper products: small toilet roll, napkin tissue, kitchen towel. (the paper can be colored, embossed and perforated)

Packaging

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipments

1 sea transportation is from qingdao seaports or other ports.

2 the delivery time is decided by your needed machines or machine parts. But it also follows your needs.

How to get your suitable machine and production lines?

1.inquiry:contact us by email,phone,fax,skype,MSN etc.

2.negotiation:after getting our quotation,you confirm the paper machine model and specify the items you desire.

3.contract:place order and signing the agreement files.

4.production:as soon as we received first payment,we will start to produce machines.we will notify client to book the ship 15days in advance.

5.delivery: all the machines will be shipped according to contracted items.

6.installation:we will send engineers/technicians to install the whole production line.

After-sales service

1. Our company view adhering to the "excellent quality, customer satisfaction" service concept, to provide you with excellent products and perfect service.

2. Our company keep the contract and reputation. Quality first, products guarantee a year, as it is quality problem, free replacement.

3. For every purchase of our company's products, the company can send technicians to guide the installation and debugging, and can undertake the design of process and equipment installation.

4. Our company ensure that supply of parts discount all the year round.

Detailed design for the whole production line:

1.Chain conveyor

2.Hydraupulper, D-type hydraupuler, Drum type hydraupulper

3.High density de-slagging machine

4.Vibrating screen, mid consistency pressure screen, paper machine pressure screen, UV-flow pressure screen, inflow pressure screen,external flow pressure screen, center section energy saving pressure screen,fiber fractionating screen,light rejects screen,double drum pressure screen, coarse screen , fine pulp screen etc.

5.PZ series reject separator, Single-effect separating machine,, single fiber separating High Quality Heavy Impurity Cleaner/waste paper recycling processing machine/paper pulp making machines machine etc.

6.Pulp pump

7.Double disc refiner, high taper fine grinding machine, double disc pulp grinding machine, conical refiner etc.

8.High taper helical propeller, square pulp pool stirrer

9.Other paper recycling machines such as grapple, cutter,drum unpacker., disc thickener, sludge dewatering machine etc.