- Product Details

- {{item.text}}

Quick Details

-

Structure:

-

Vertical or Horizontal

-

Control System:

-

Auto & Manual

-

Operation:

-

PLC Touch Screen

-

Technology:

-

Multi Arc + Sputtering

-

Process:

-

Green

-

Color:

-

Gold, Rose Gold, Blue, Gray, Black, Rainbow

-

Working Way:

-

Pumping to Coat

-

Machine Size:

-

Custom Made

Quick Details

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Chamber Material:

-

Stainless Steel 304

-

Structure:

-

Vertical or Horizontal

-

Control System:

-

Auto & Manual

-

Operation:

-

PLC Touch Screen

-

Technology:

-

Multi Arc + Sputtering

-

Process:

-

Green

-

Color:

-

Gold, Rose Gold, Blue, Gray, Black, Rainbow

-

Working Way:

-

Pumping to Coat

-

Machine Size:

-

Custom Made

Foshan Foxin Vacuum Technology Company is focusing on vacuum coating equipment manufacture. We are committed to providing high quality vacuum equipment, central technical support, personalized solutions and considerable after-sales service.

Main products: Stainless Steel Tableware Coating Machine, Sanitary Ware Coating Machine, Glass Mosaic Coating Machine, Ceramic Tile Coating Machine, Hardware Coating Machine, Large Furniture Frame Coating Machine, Stainless Steel Sheet Coating Machine, etc. Our equipment is widely used in building materials, large hardware, clock, cell phone, aerospace, electron, toy, computer components, automobile decoration, etc. In addition, we provide technical supports to our customers, and also we serve various kinds of accessories and consumables.

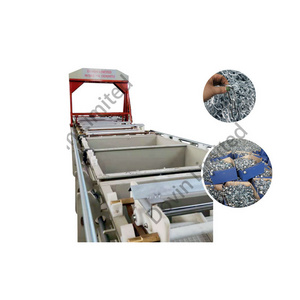

Motorcycle Rims Chrome Plating/Chrome Plating Machine for Wheels/Hard Chrome Plating Equipment

Working Principle: Cathodic arc deposition or Arc-PVD is a physical vapor deposition technique in which an electric arc is used to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film. The technique can be used to deposit metallic, ceramic, and composite films.

We can custom made machine size and configuration according to customer’s request.

Technical Parameters:

|

FOXIN-IP Series Parameters |

||||||

|

Model |

IP-1010 |

IP-1012 |

IP-1212 |

IP-1412 |

IP-1413 |

IP-1215 |

|

Chamber Size(mm) |

D1000xH1000 |

D1000xH1200 |

D1200xH1200 |

D1400xH1200 |

D1400xH1300 |

D1200xH1500 |

|

Pumping System |

Rough Pump + Roots Pump + Diffusion Pump(Turbo Pump) + Hold Pump |

|||||

|

Measurement |

1 set pirani, 1 set cold cathode, 1 set diaphragm gauge |

|||||

|

Arc Source |

6 |

8 |

12 |

12 |

12 |

14 |

|

Arc Power Supply |

200A |

|||||

|

Magnetron Target |

DC or MF, Plane or Cylinder |

|||||

|

Magnetron Power Supply |

DC or MF, 30 or 40 kW |

|||||

|

Bias Power Supply |

30 kW |

|||||

|

Gas |

Ar, N2, C2H2, O2 |

|||||

|

Cooling |

Water cooling circulation, equip with industrial cooling tower or industrial water chiller(refrigerating machine)

|

|||||

|

Vacuum Index |

Extract time (no load cold state): from atmosphere to 9.9×10 -3 Pa≤10min |

|||||

|

Ultimate Vacuum |

Superior to 5.0x10 -4 Pa |

|||||

|

Pressure Rising Rate |

New machine cold state air leaking rate≤0.5Pa/h |

|||||

|

Running Power(kW) |

According to specific configuration |

|||||

|

Output Frequency |

Custom made |

|||||

|

Occupation Space(m2) |

8 |

10 |

12 |

12 |

12 |

12 |

|

Accessory Equipment |

Oven, Water Tower, Water Pump, Air Compressor, Jig Rack, Water Tank or Pool |

|||||

|

Remark |

All configuration can be custom made |

|||||

Here you can find details of our machines.

Whole Process of PVD Vacuum Coating Machine

Inspection: Ultrasonic leak detector, certain vacuum index, trial coating

Our machines offer popular colors like gold, rose gold, silver, blue, gray, black and rainbow, here you can see some samples coated by our machines. Also we can coat green, pink color.

Customers visit our factory and discuss cooperation matters

O ur factory

Our certifications

S ome exhibitions we have attended

After Sales Service: If you have any after sales problem, we will solve by phone, wechat, whatsapp, QQ such chatting tools; If still, we will send engineer to your factory to fix the problem .

One stop solution: We will offer all consult service about setting up a PVD coating plant.

PVD coating is total green plating process and it is future trend in surface treatment industry.

You may send us your inquiry. Hope to cooperate with you!