- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Type:

-

Hard Cover Maker

-

Place of Origin:

-

Zhejiang, China

- Product Description

Item Name: HL - M450A/550A/600A Full automatic Hard cover Making Machine

Description:

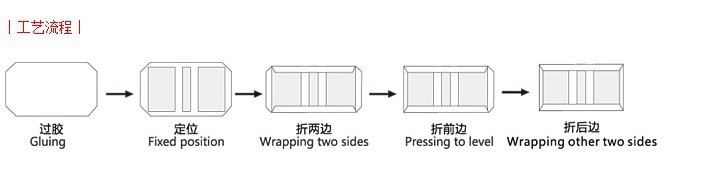

This machine is equipped with automatic feeder and paperboard automatic positioning device, ultrasonic double-sheet detection and pneumatic control pressure angle function, desktop stack transport and discharge, and the operation is quick and convenient. It is the latest equipment for making hardcover book cases, notebooks, covers, calendars, folders, and more.

1. The feeder of this machine adopts the automatic paper feeding structure and it is fully pneumatically controlled. The structure is simple and reasonable.

2. The width adjustment of the stacking platform and the paper-feeding platform adopts center concentric adjustment, and the operation is simple and error-free.

3. The newly designed copper scraper is used in the gluing section to effectively prevent paper-rolling and ensure the normal operation of the machine.

4. It adopts imported ultrasonic double-sheet detection device, which has simple operation setup and effectively prevents double-sheets feeding.

5 The cardboard feeder uses linear guides and is accurate.

6. There is cardboard automatic stop device in the cardboard feeding table if there is a lack of paper, reducing the product scrap rate.

7. The conveyor belt adopts high-power suction fan to make the paper transport more stable and accurate.

8. The paper conveying and positioning system adopts imported high-precision photoelectric control device to make the positioning of paper and paperboard more accurate and reliable.

9. The rear automatic edge folding machine adopts a unique automatic crimping and pressing mechanism to ensure the qualified rate of finished products.

10. The receiving platform adopts a desktop stack for feeding and discharging, which makes it easier to receive materials.

Detailed Data:

|

Model No. |

HL- M450A |

HL- M540A |

HL- M600A |

|

paper sheet size(A×B) |

MIN: 130×230mm MAX: 480×830mm |

MIN: 130×230mm MAX: 570×1030mm |

MIN: 130×230mm MAX: 630×1030mm |

|

P aper thickness |

100~200g/m 2 |

100~200g/m 2 |

100~200g/m 2 |

|

C ardboard thickness(T) |

1~3mm |

1~3mm |

1~3mm |

|

finished product size(W×L) |

MIN: 100×200mm MAX: 450×800mm |

MIN: 100×200mm MAX: 540×1000mm |

MIN: 100×200mm MAX: 600×1000mm |

|

spine(S) |

10mm |

10mm |

10mm |

|

Folded paper size ( R ) |

10~18mm |

10~18mm |

10~18mm |

|

M ax quantity of cardboard |

6pieces |

6pieces |

6pieces |

|

P recision |

±0.50mm |

±0.50mm |

±0.50mm |

|

S peed |

25sheets/min |

25sheets/min |

25sheets/min |

|

M otor power |

5kw/380v 3phase |

5kw/380v 3phase |

5kw/380v 3phase |

|

H eater power |

6kw |

6kw |

6kw |

|

W eight |

3000kg/3200kg |

3500kg/3900kg |

3700kg/4200kg |

|

M achine dimension |

L8200 * W2200 *H1600 mm x |

L9000 * W2300 *H1600 mm |

L9000 * W2400 *H1600 mm |