- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Rotexmaster

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2600*1300*2300mm

-

Weight (KG):

-

5800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Kenaf

-

Capacity:

-

1-1.5t/h

-

Pellet size:

-

4-12mm

-

Motor:

-

SIEMENS Brand

-

Power(W):

-

90kw

-

Weight:

-

5.5T

Quick Details

-

Pellet Diameter (mm):

-

6 - 8

-

Output (kg/h):

-

1000 - 1500 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rotexmaster

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2600*1300*2300mm

-

Weight (KG):

-

5800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Kenaf

-

Capacity:

-

1-1.5t/h

-

Pellet size:

-

4-12mm

-

Motor:

-

SIEMENS Brand

-

Power(W):

-

90kw

-

Weight:

-

5.5T

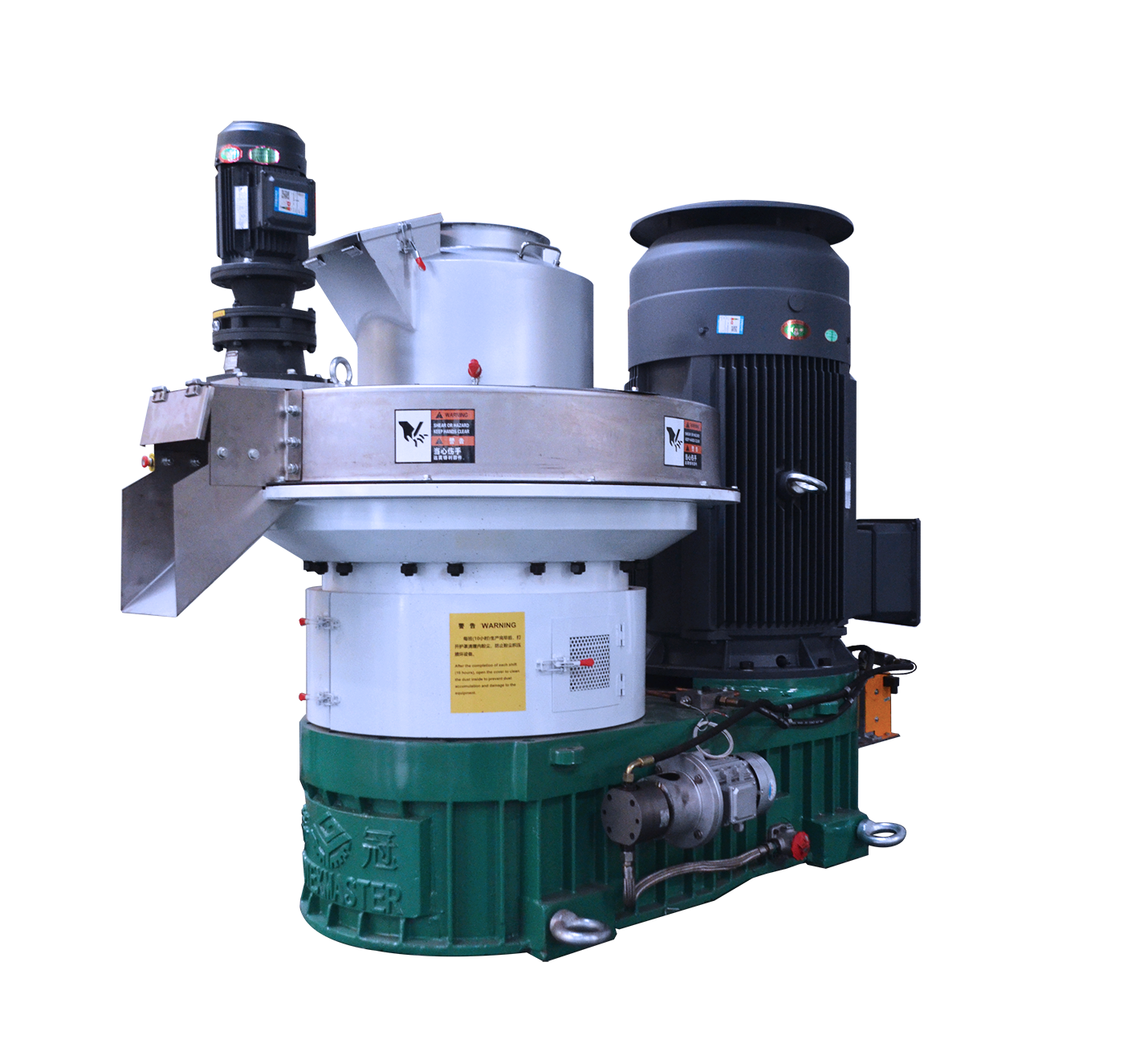

vertical ring die YGKJ560 Rotexmaster wood pellet machine ,

1. its main power 90kw ,have fan blower 0.37kw, reducer 0.55kw, fan blower :1.5kw, outlet click disc 1.5kw ,equiped with simens beide motor , not easy to broken when current burnden

2. capacity 1-1.5t/h, with power 90kw, capacity is partly decided by raw material , the wood pellets density ≥1.1, 1.1 -1.3kg/m^3 ,

pellet daimeter 4-12mm, ,usual 6mm and 8mm , pellet moisture :8%-10%

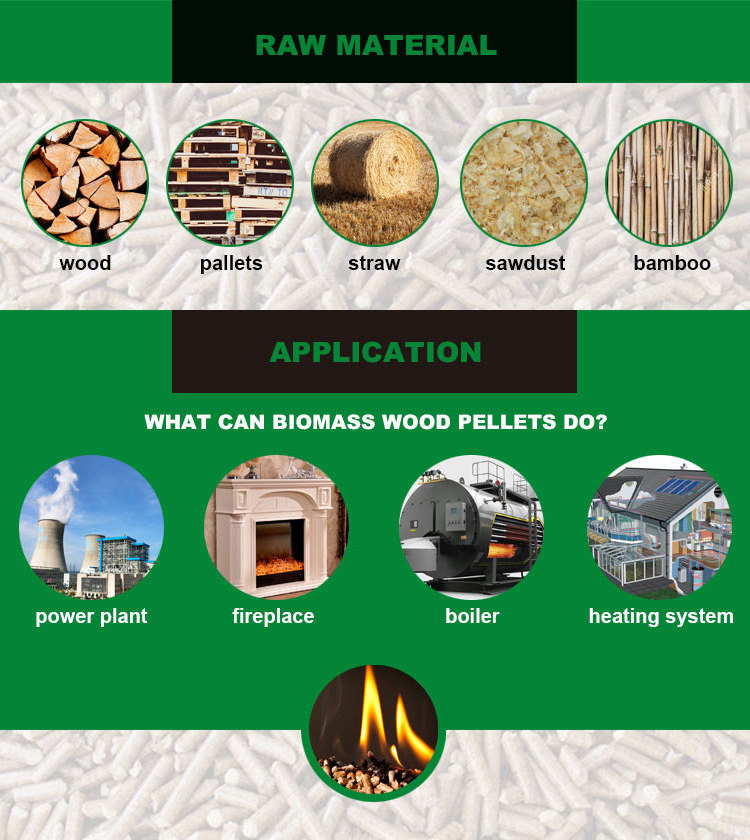

3.. Th e raw materials for pellet machine are easy to obtain, like groundnut shell, sawdust, paddy straw, wheat straw, efb palm husk, rice husks, etc and many other agro and forestry wastes , wood waste , olive waste ,also can mix the material together .

Wood pellet making machine parameter

|

Model |

Power KW |

Pellet Diameter mm |

Output kg/h |

Dimension mm |

Weight t |

|

YGKJ560 |

90+1.5+0.37+1.5 |

4-12 |

1-1.5 |

2600*1300*2300 |

5.8 |

|

YGKJ680 |

160+1.5+0.37+1.5 |

4-12 |

1.5-2.5 |

3300*1500*2300 |

8.5 |

|

YGKJ850 |

220+3+0.37+2.2 |

4-12 |

2.5-3.5 |

3800*1830*3080 |

15 |

1. Vertical feeding directly in place. centrifugual force is enoug h , Never ouccur materail block without wrong operation and the bearings in the main shaft is wear-resistant,avoid the bearing break because of over press.

2 . Die static, roller rotating, materials centrifugal, Evenly distributed around. make wood pellets more smooth surface

3.Double-layer dies, up and down dual-use, reduce the cost, enhance the efficiency, can be dual-use, high capacity, energy saving. our stainless steel die service life is 1000-1500hrs

4.Ring die, vertical structure, and cooling system -fan blower good for cooling the pelletizing room.

5.Independent and frequency conversion discharge device, to ensure that the rate of pellet formation

6 .Automatic lubrication system , lubricate the bearings without stop , make our wood pellet machine can work at least 20 hrs , work 24hrs , but we recommend operate 20hrs .

7 .Superior equipment : Siemen Beide motor , Harbin Standard bearing

More wood pellet plant cases

some questions about wood pellet machine .

Q1: what is the raw material to make wood pellet , if any requirements for the raw material?

A1: raw material ca be wood waste , shells, tree branch , straw, stalk, bamboo, etc including fiber the raw material is no limitation , but the direct material to make wood pellet is wood powder ()not more than 8m), and mositure is 12%-20%,

so if your material is not wood powder and moisture is more than 20%,u need other machines, such as wood crusher ,wood hammer mill and dryer etc

Q2: if your wood pellet machine can make EN plus standard pellet ?

A2:yes, our veertical ring die wood pellet machine can make density 1.3kg/m^3 wood pellet , mositure is 8% , ash <1%(decided by raw material)

Q3: will u install the wood pellet line overseas ?

A3: yes, we have 6 installation teams, they have experience in installation in overseas